Electric lubricating grease and preparation method thereof

A technology of lubricating grease and electric power, which is applied in the field of electric lubricating grease and its preparation, can solve problems such as poor electrical conductivity, achieve the effects of reducing contact resistance, improving electrical conductivity and protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

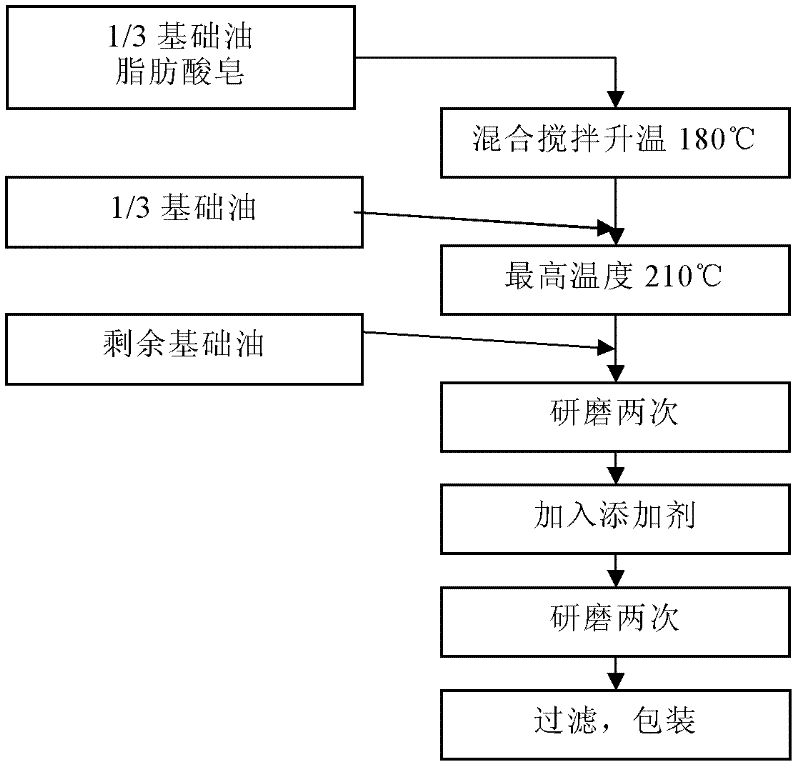

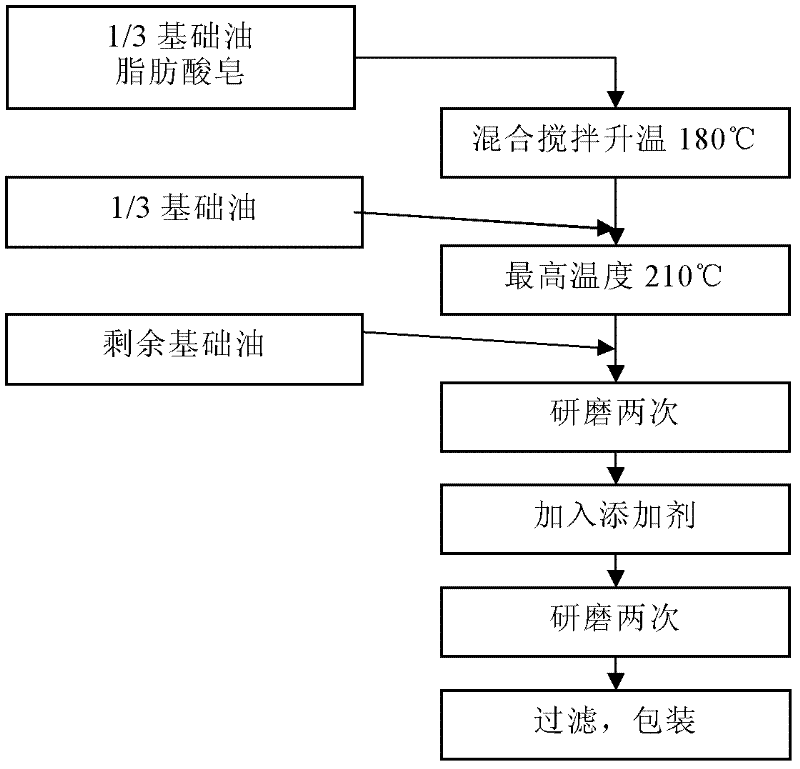

Method used

Image

Examples

Embodiment 1

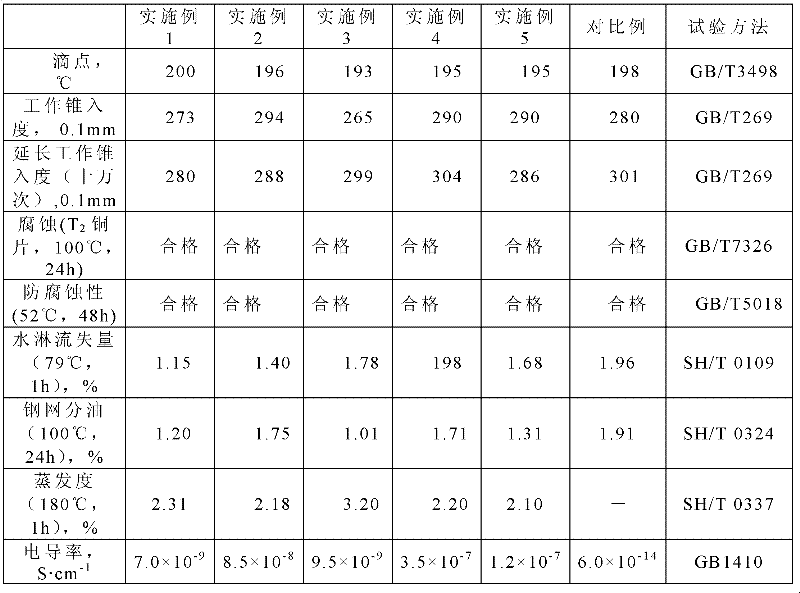

[0024] Mix 20 parts of type II mineral oil and 9.0 parts of lithium lauryl hydroxystearate soap, raise the temperature to 180, add 20 parts of type II mineral oil, raise the temperature to 210, add 20 parts of type II mineral oil, grind twice and then add 0.15 1 part of diisooctyl diphenylamine, 0.15 part of benzotriazole, 0.30 part of barium dinonyl naphthalene sulfonate, 30 parts of metal copper powder, 0.40 part of T1501 additive, stirred and ground twice, filtered and packaged to obtain grease finished product. The physical and chemical indicators are shown in Table 1.

Embodiment 2

[0026] Mix 20 parts of polyalphaolefin synthetic base oil, 7.0 parts of lithium lauryl stearate soap and 2.0 parts of tertiary lithium stearate soap, raise the temperature to 180, add 10 parts of polyalphaolefin synthetic base oil and 10 parts of type II Mineral oil, heat up to 210, add 20 parts of type II mineral oil, grind twice and add 0.15 parts of diisooctyl diphenylamine, 0.15 parts of benzotriazole, 0.30 parts of barium dinonyl naphthalene sulfonate, 20 parts of metal Copper powder, 10% metal nickel powder, 0.40 part of T1501 additive, after stirring, grind twice, filter and pack to obtain the finished lubricating grease. The physical and chemical indicators are shown in Table 1.

Embodiment 3

[0028] Mix 20 parts of ester synthetic base oil, 7.5 parts of lithium lauryl stearate soap and 1.5 parts of calcium lauryl stearate soap, raise the temperature to 180, add 10 parts of synthetic ester base oil and 10 parts of type II mineral Oil, heat up to 210, add 20 parts of type II mineral oil, grind twice and add 0.15 parts of diisooctyl diphenylamine, 0.15 parts of benzotriazole, 0.30 parts of dodecenylsuccinic acid, 30 parts of metal zinc Powder, 0.40 parts of T1501 additive, stirred and ground twice, filtered and packaged to obtain finished grease. The physical and chemical indicators are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com