Thermal-radiation internal-circulation power generation device

A power generation device and internal circulation technology, applied in solar thermal power generation, machines/engines, and mechanical power generation with solar energy, etc., can solve the problems of traditional backward mode, low heat conversion efficiency, easy heat dissipation, etc., and achieve no scale, boiling point, etc. High, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

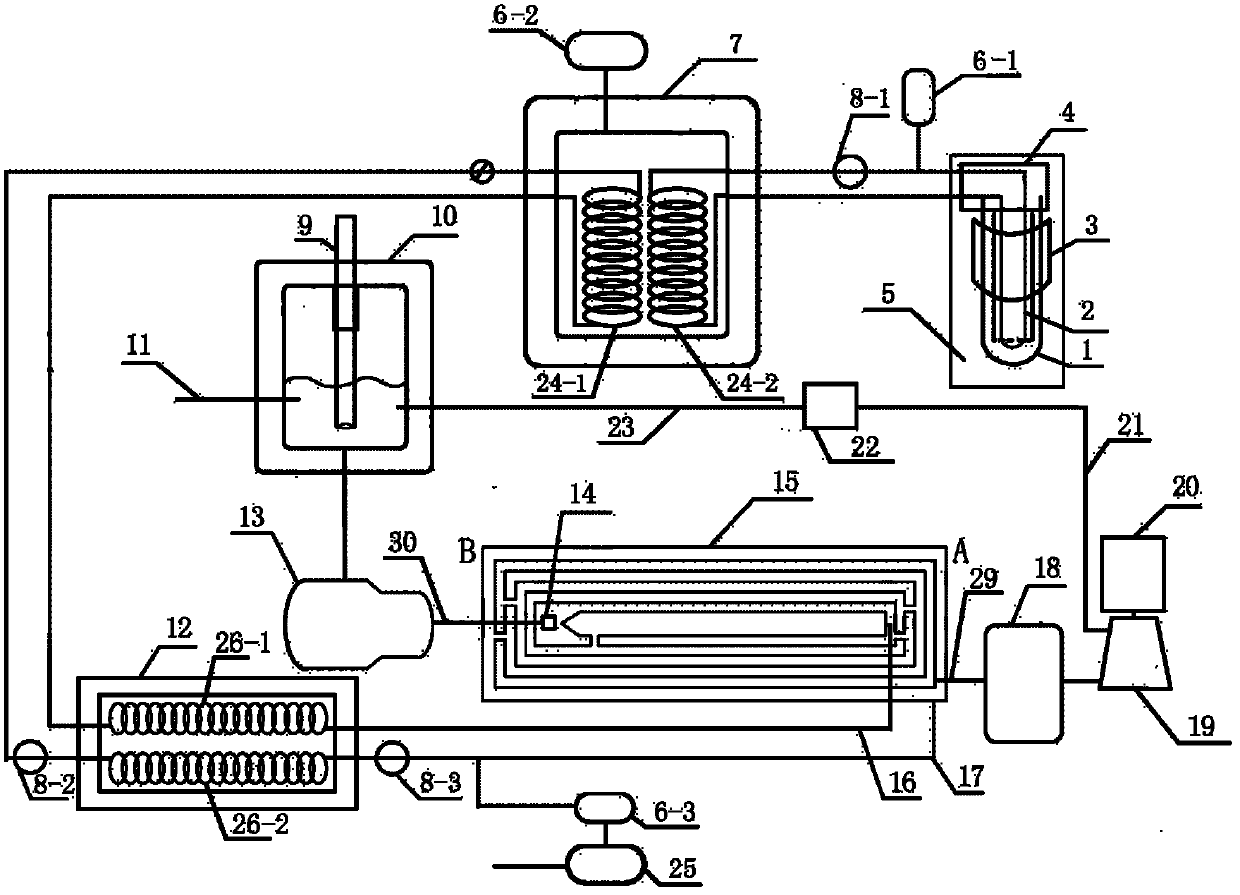

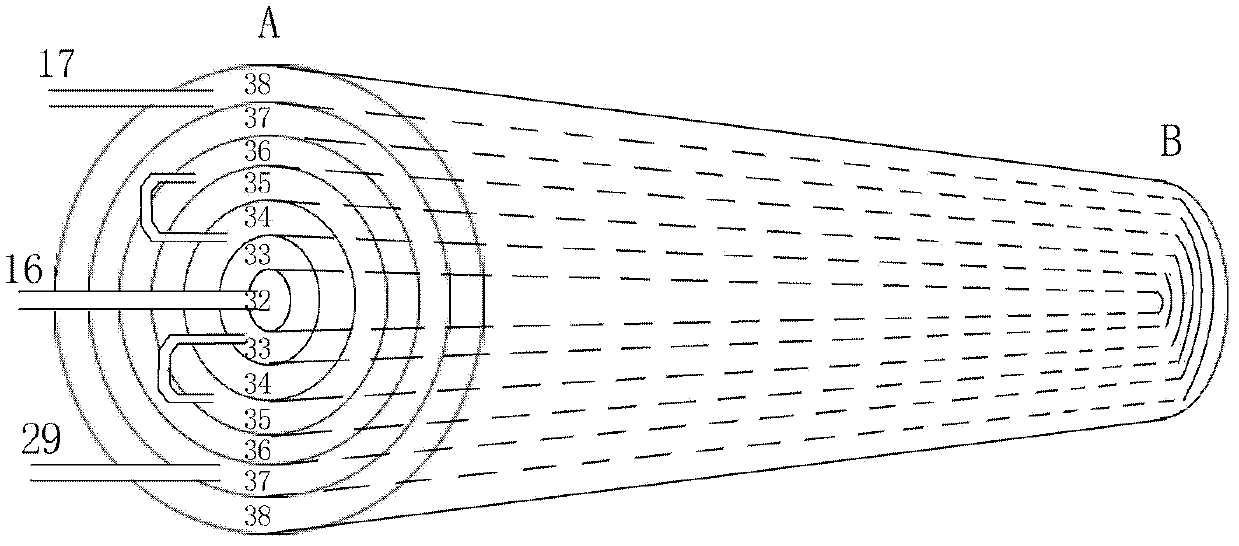

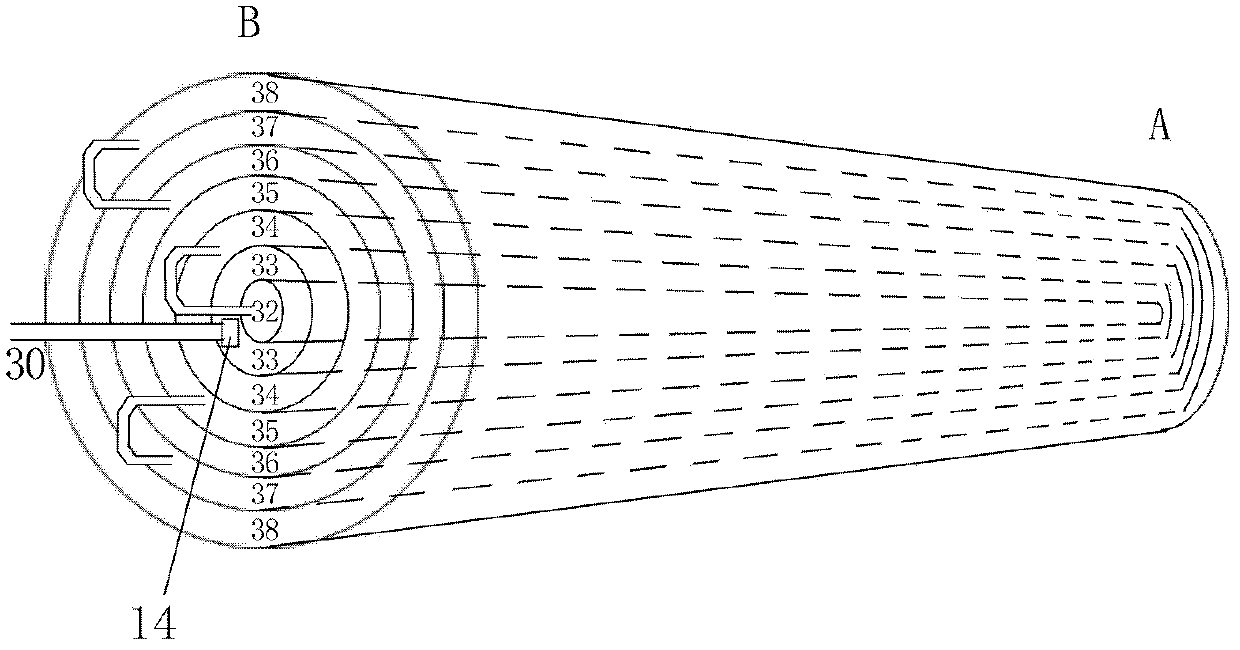

[0032] Tube heat radiation internal circulation power generation device: when the sun is sufficient, such as figure 1As shown, the solar tube 5 is connected to the first heat conduction coil 24-2 in the energy storage tank 7 through the inlet and outlet through two pipes in the connection box 4 . The energy storage tank 7 has an insulation layer and is connected with the high-level expansion tank 6-2, and the inside of the tank body is empty for containing saline solution. One of the pipelines connecting the energy storage tank 7 and the solar tube 5 is equipped with a circulating pump 8-1 and is connected to the high-level expansion tank 6-1. The heat conduction coil 24-1 in the energy storage tank 7 is connected to the inlet oil pipe of the third heat conduction coil 26-1 of the constant temperature furnace 12 through an outlet pipeline, and a circulation pump 8-2 is housed on this pipeline; There are expansion and contraction devices 9 and soft water replenishment pipes 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com