Multi-stage utilization system for transferring exhaust afterheat energy of power station boiler

An energy transfer, power station boiler technology, applied in preheating, feed water heaters, lighting and heating equipment, etc., can solve the problems of limited increase in flue gas temperature, limited increase in air temperature, loss of cold source, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

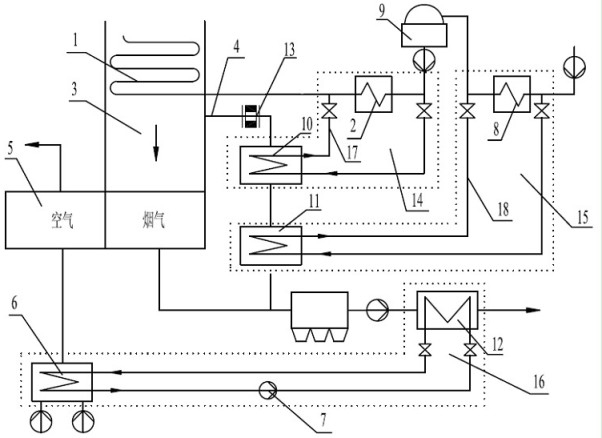

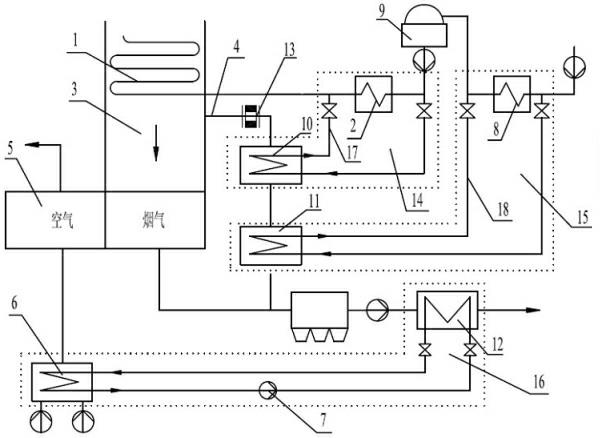

[0034] The best embodiment of the present invention is illustrated below in conjunction with accompanying drawing:

[0035]When the present invention works, the low-temperature flue gas flowing out from the air preheater 5 enters the third-stage flue gas cooler 12 to release heat and reduce the outlet temperature of the flue gas. This part of the flue gas waste heat is used to heat the independent circulating medium of the third-stage flue gas cooler. After its temperature is increased, it enters the boiler heater 6 to heat the cold air entering the air preheater 5, so that the air entering the air preheater 5 The cold air temperature increases. Adjust the flue gas regulator 13 to gradually increase the amount of flue gas passing through the bypass flue 4, and this part of high-temperature flue gas flows through the first-stage flue gas cooler 10 and the second-stage flue gas cooler 11 in sequence to release heat. The temperature of the flue gas at the outlet decreases, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com