Method for determining water content in glyceryl triacetate

A technology of triacetin and moisture, applied in measurement devices, material separation, analysis of materials, etc., can solve the problems of irregularity, large influence of environmental temperature and humidity, single method, etc., achieve good linear correlation, improve sensitivity, repeatability, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

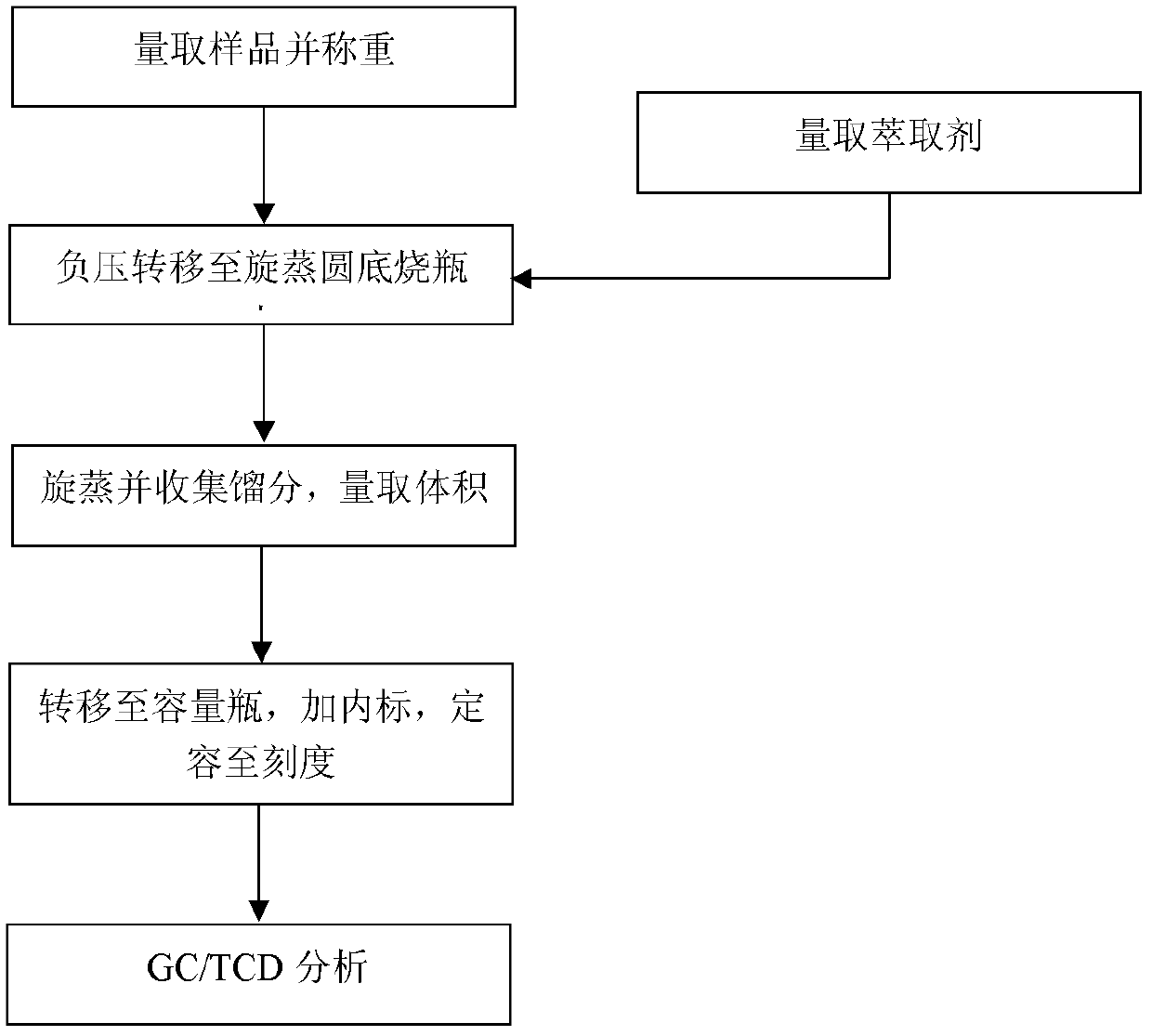

[0029] Determination of moisture content in glycerol triacetate (determination method flow chart is as figure 1 shown):

[0030] 1. Preparation of internal standard solution: pipette 25mL ethanol (chromatographically pure) into a 100mL volumetric flask, dilute to the mark with isopropanol and mix to obtain an ethanol internal standard solution with a volume ratio concentration of 25% for later use. The internal standard solution was sealed and stored in a refrigerator at 4°C, and the validity period was 3 months.

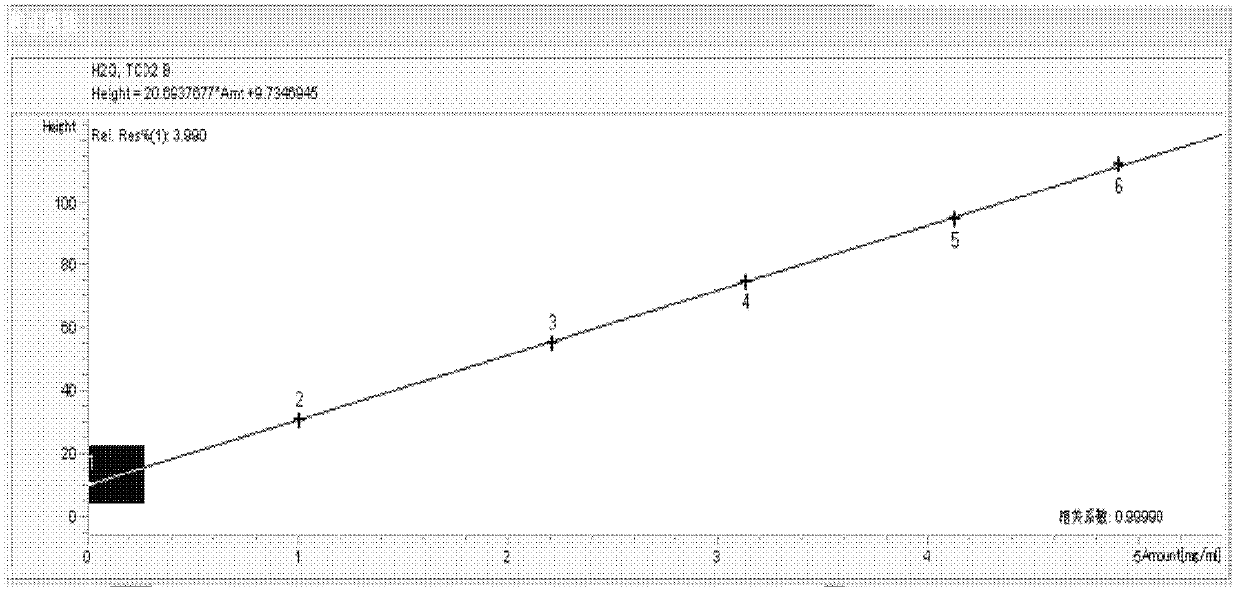

[0031] 2. Preparation of standard working solution: Accurately weigh 0, 50, 110, 160, 200, 250mg of pure water in a 50mL volumetric flask, then add 1mL, 25% ethanol internal standard solution (volume ratio concentration), use Dilute the volume of isopropanol to the mark and mix evenly to obtain standard working solutions with 6 concentration levels. The standard working solutions need to be prepared and used immediately. As shown in Table 1:

[0032] Table 1 Work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com