Method for preparing chalcopyrite thin-film solar cells

A solar cell, chalcopyrite-based technology, applied in circuits, electrical components, final product manufacturing, etc., can solve the problem of high cost and achieve the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

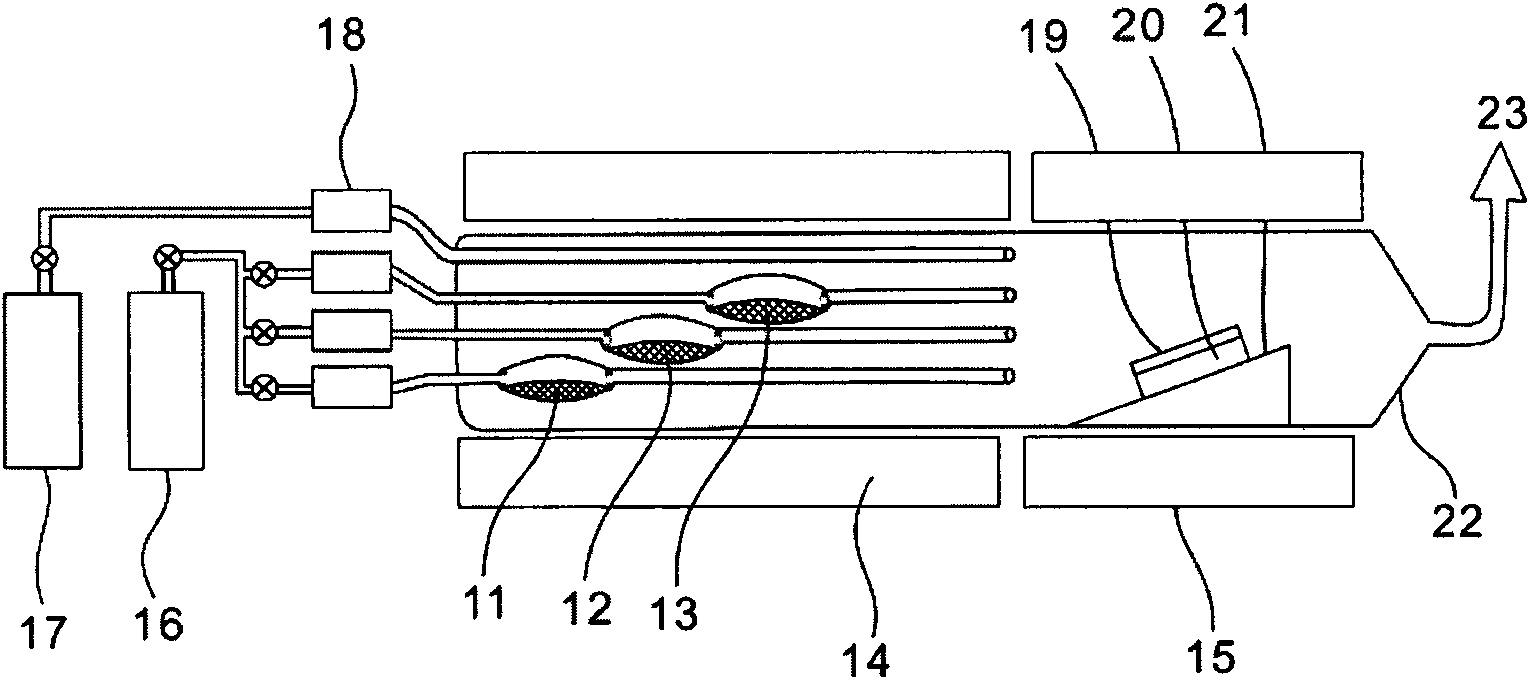

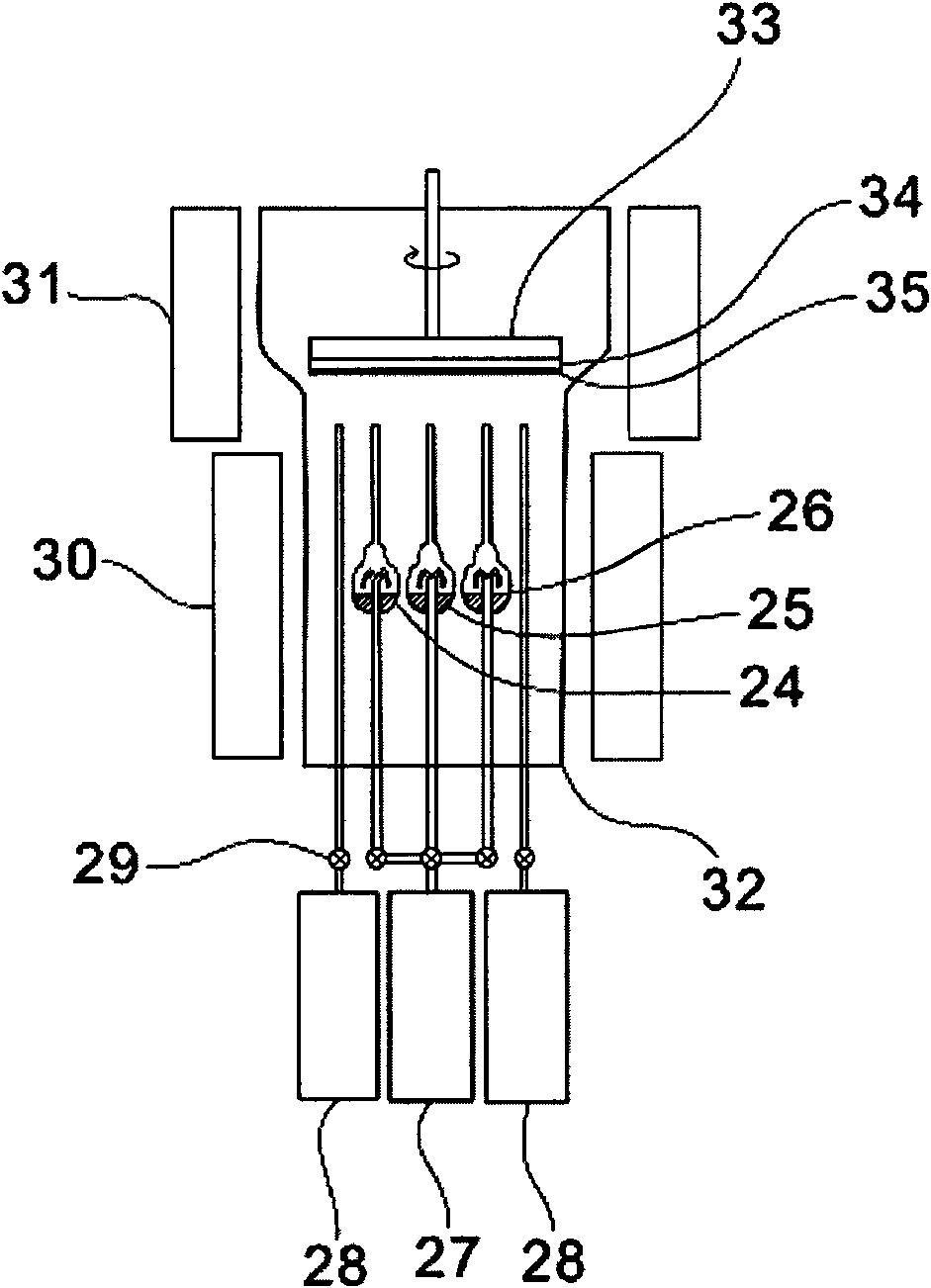

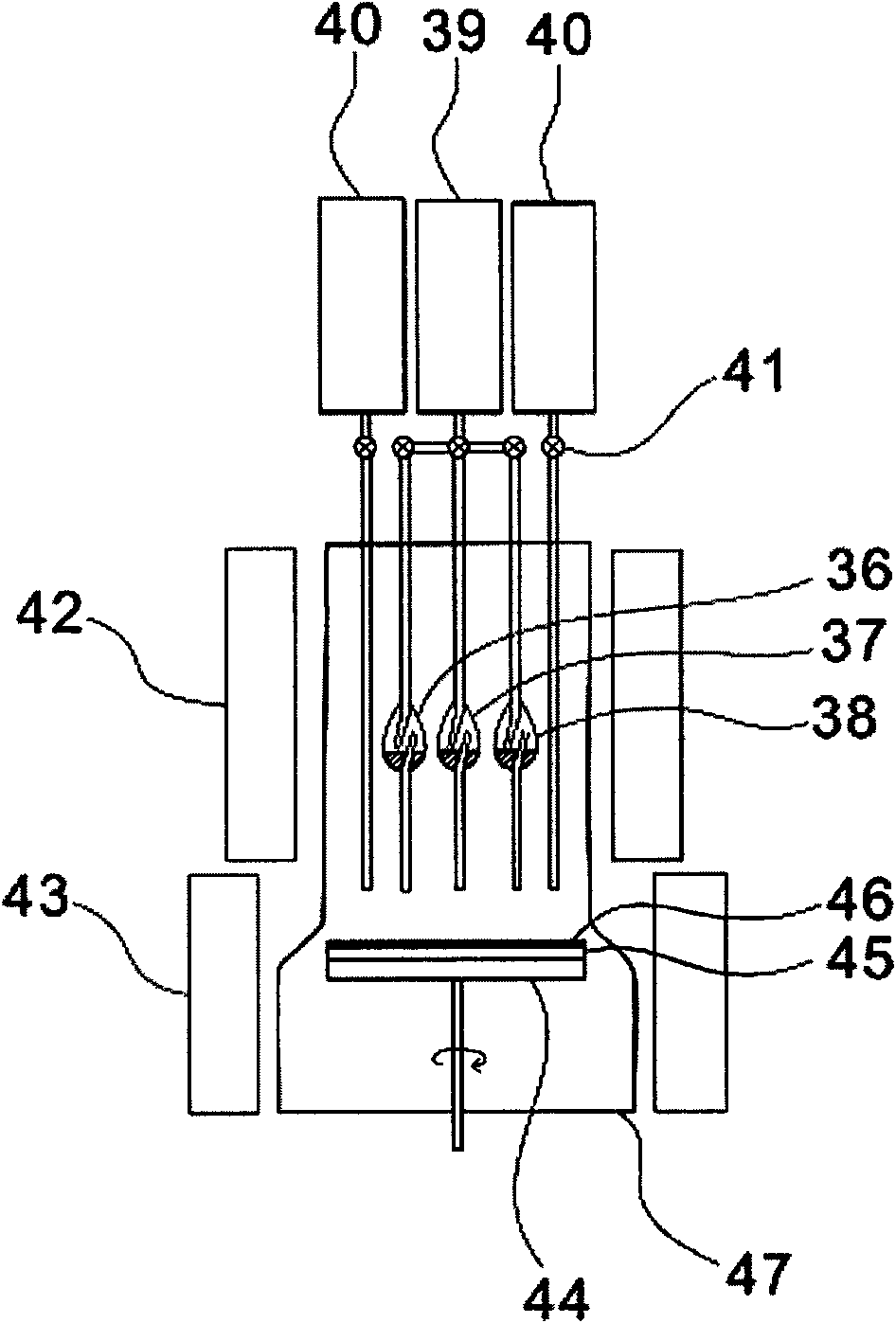

[0027] The invention relates to a preparation method of a chalcopyrite-based thin-film solar cell. The method uses in-situ generation of reaction precursors and cooperates with vapor phase epitaxy growth technology to prepare selenium / copper indium gallium sulfide series and selenium / copper zinc-tin sulfide series. Light-absorbing layer of thin-film solar cells. Among them, in the step of in-situ generation of reaction precursors, metals such as copper, indium, gallium, or copper, zinc, and tin are placed in a crucible heated to 400 degrees Celsius to 1,000 degrees Celsius, and hydrogen chloride or chlorine gas is used to generate copper, zinc, and tin in situ. The reaction precursors of metal chlorides such as indium, gallium or copper, zinc, tin, etc., the reaction formula is as follows:

[0028] (1) Copper (Cu) → copper chloride (CuCl)

[0029] 2Cu+2HCl→2CuCl+H 2

[0030] 2Cu+Cl 2 →2CuCl

[0031] (2) Indium (In) → indium chloride (InCl, InCl 3 )

[0032] 2In+2HCl→2In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com