Conjugated thin polymer film solar cell and method for producing same

A technology of conjugated polymers and solar cells, applied in the field of solar cells, can solve the problems of low energy conversion efficiency, achieve the effect of reducing the electron output potential barrier and increasing the short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

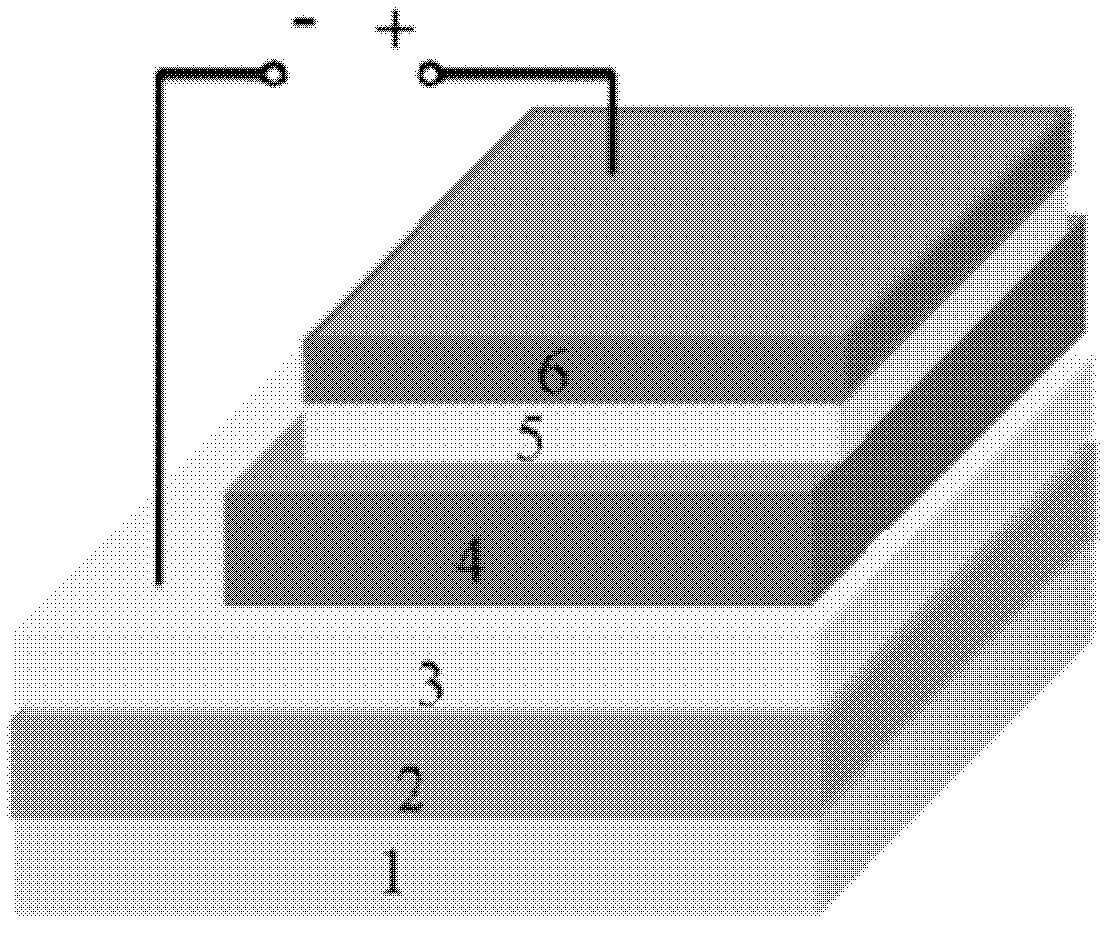

[0032] The present invention also provides a preparation method of a conjugated polymer thin film solar cell, comprising the following steps:

[0033] (1) forming a cathode layer on the substrate;

[0034] (2) vapor-depositing a compound of molybdenum trioxide-aluminum on the above-mentioned cathode layer to form a cathode interface buffer layer;

[0035] (3) On the above-mentioned cathode interface buffer layer, a blend composed of a conjugated polymer and a fullerene derivative is coated to form a photosensitive layer;

[0036] (4) An anode interface buffer layer and an anode layer are sequentially vapor-deposited on the photosensitive layer to obtain a conjugated polymer thin film solar cell.

[0037] The substrate is glass or a flexible substrate, the cathode layer is indium tin oxide (ITO), the cathode interface buffer layer is a composite of molybdenum trioxide-aluminum, and aluminum in the composite of molybdenum trioxide-aluminum The mass percentage is 25%-83%, prefera...

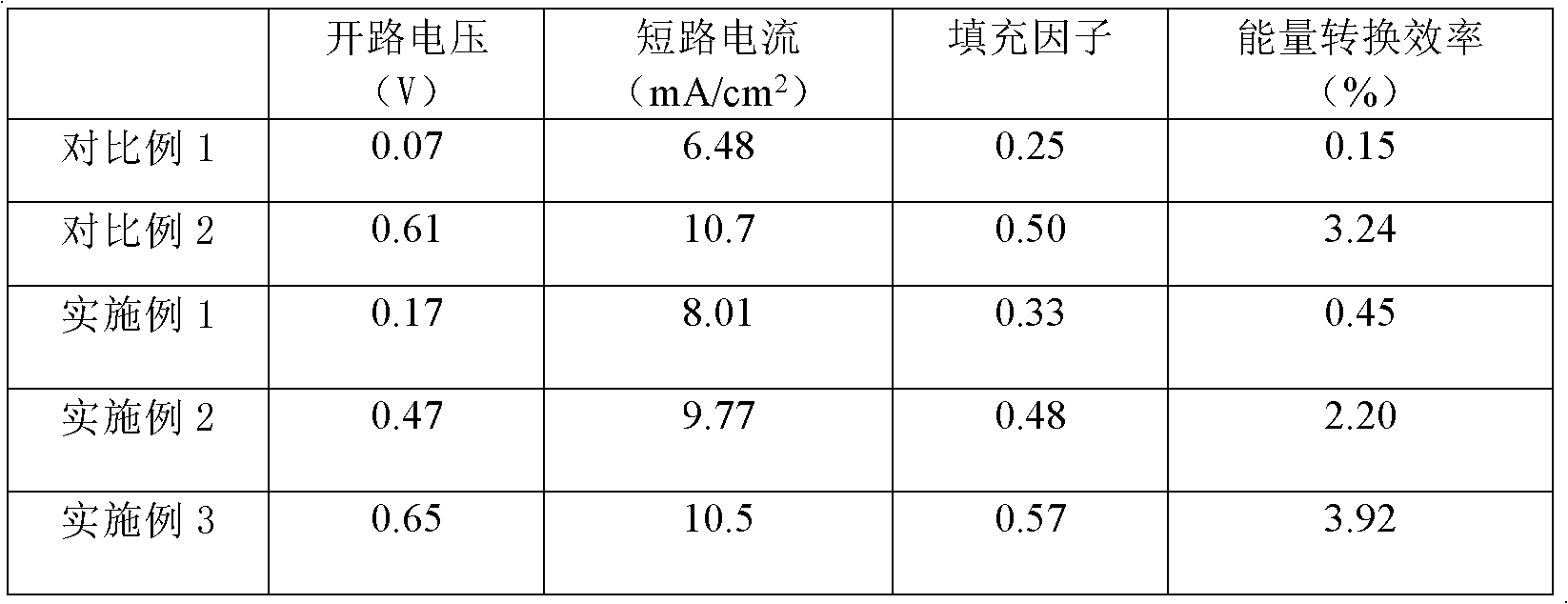

Embodiment 1

[0044] In an inert atmosphere glove box, 4 mg of poly[nitrogen-(1-octylnonyl)-2,7-carbazole-alternate-5,5-(4′,7′-bis-2-thienyl-2 ', 1', 3'-benzothiadiazole)] (PCDTBT) with 16 mg of [6,6]-phenyl C71 butyric acid methyl ester (PC 70 BM) was dissolved in 1 ml of o-dichlorobenzene, and stirred magnetically for 12 hours at 40° C. to obtain a mixed solution, the concentration of PCDTBT being 4 mg / ml; PC 70 The BM concentration was 16 mg / ml.

[0045] On the glass substrate, etch the indium tin oxide anode layer with a thickness of 120 nanometers into thin strips with a width of 4 mm, clean the etched thin strips of ITO glass, put them in an oven, and dry them at 120 ° C. Put the above-mentioned cathode layer into a vacuum coating machine to evacuate, when the vacuum degree reaches 4×10 -4 Evaporate 10nm cathode interface buffer layer MoO at Pascal 3 -Al, wherein the mass percentage of Al is 25%, the above with MoO 3 -The substrate of the Al cathode interface buffer layer is trans...

Embodiment 2

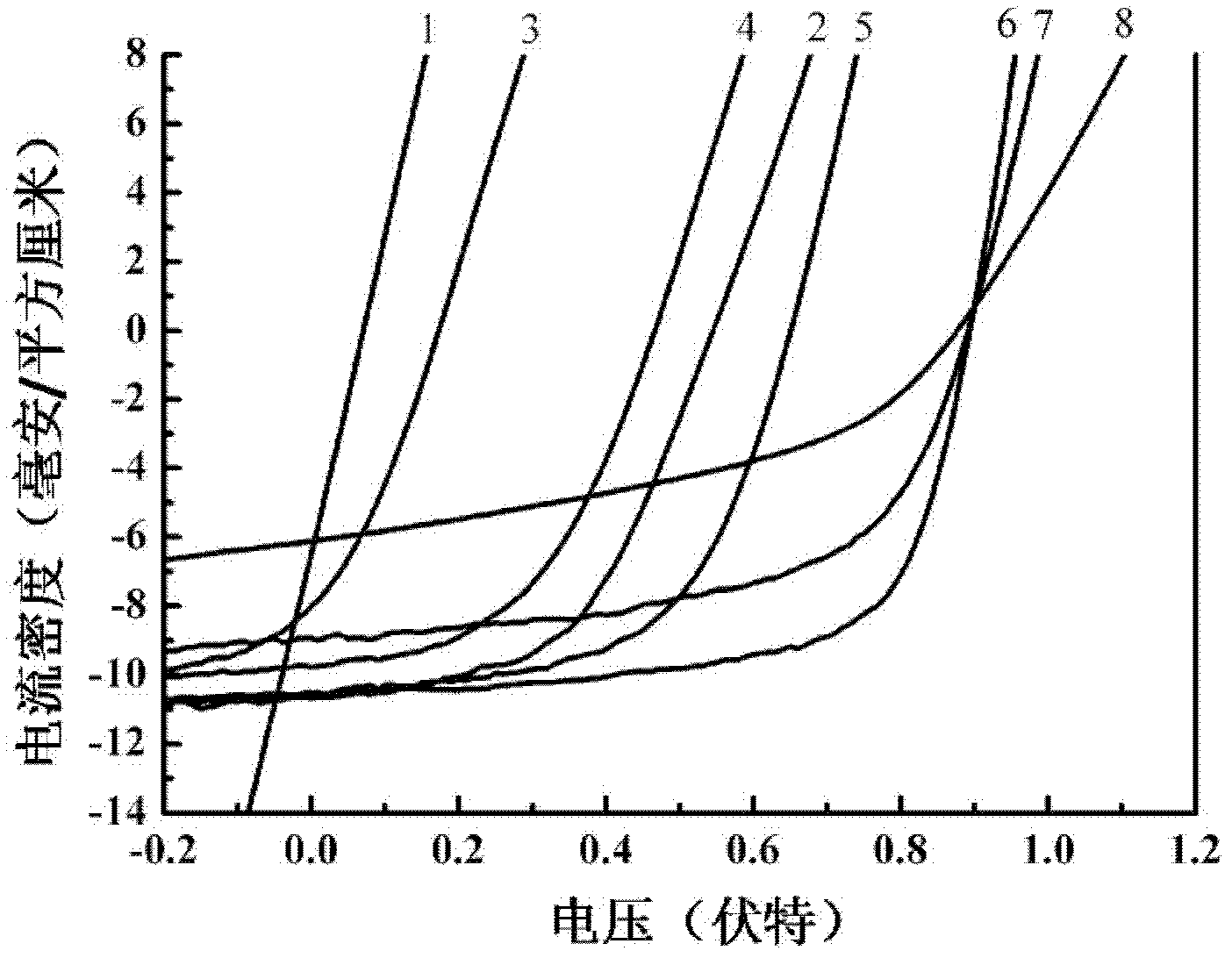

[0047] The device structure and preparation method of the conjugated polymer thin film solar cell are the same as in Example 1, except that the buffer layer MoO at the cathode interface 3 -In Al, the mass percentage of Al is 33%, and the structure is ITO (120nm) / MoO 3 -Al(33%, 10nm) / PCDTBT: PC 70 BM(70nm) / MoO 3 (6nm) / Al(80nm) conjugated polymer thin film solar cells. The performance parameters of the conjugated polymer thin film solar cell prepared in this embodiment under the AM 1.5G simulated sunlight with an intensity of 100 mW / cm2 are shown in Table 1, and the current-voltage characteristic curves tested under this condition are as follows figure 2 Shown in curve 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com