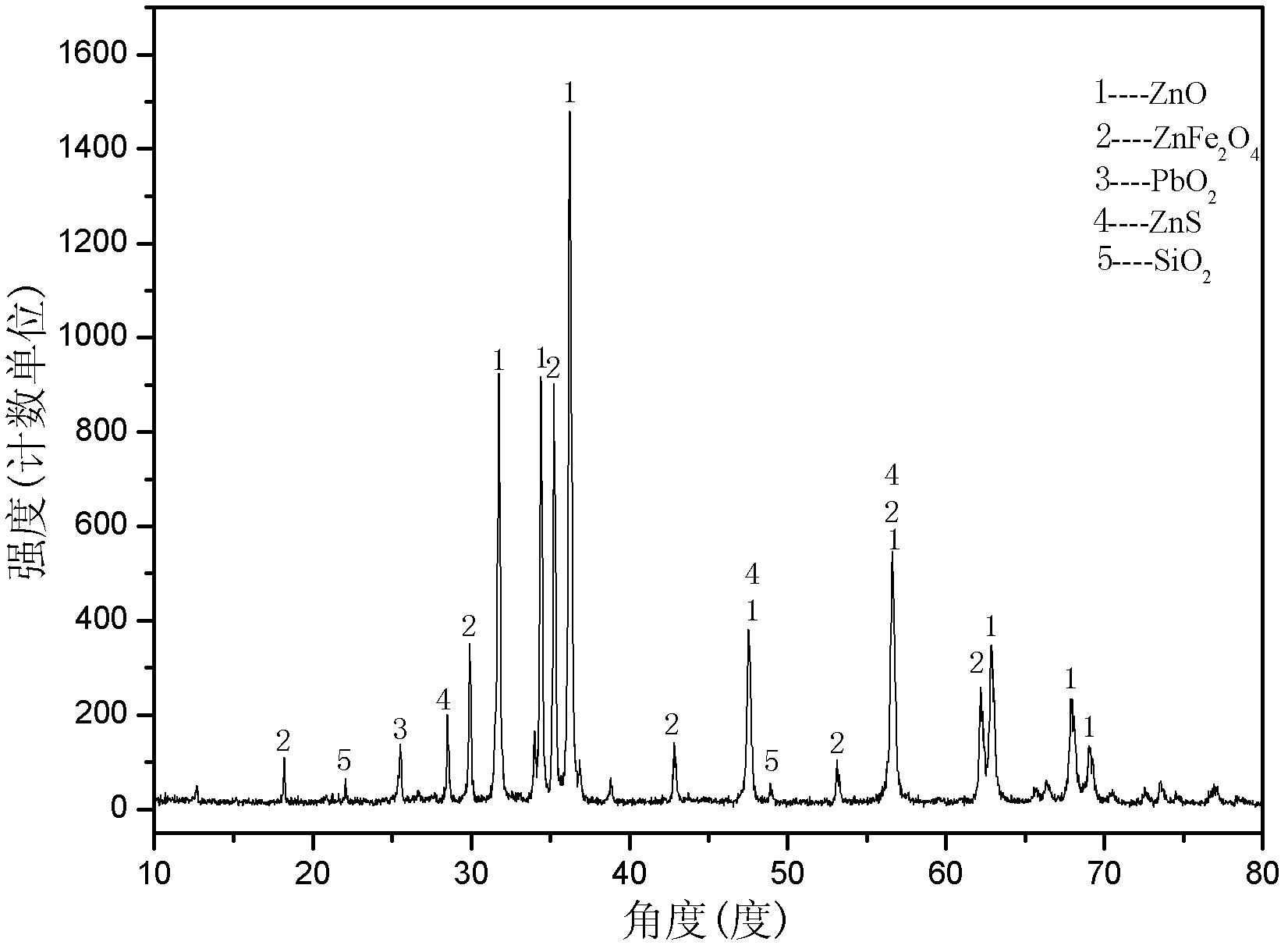

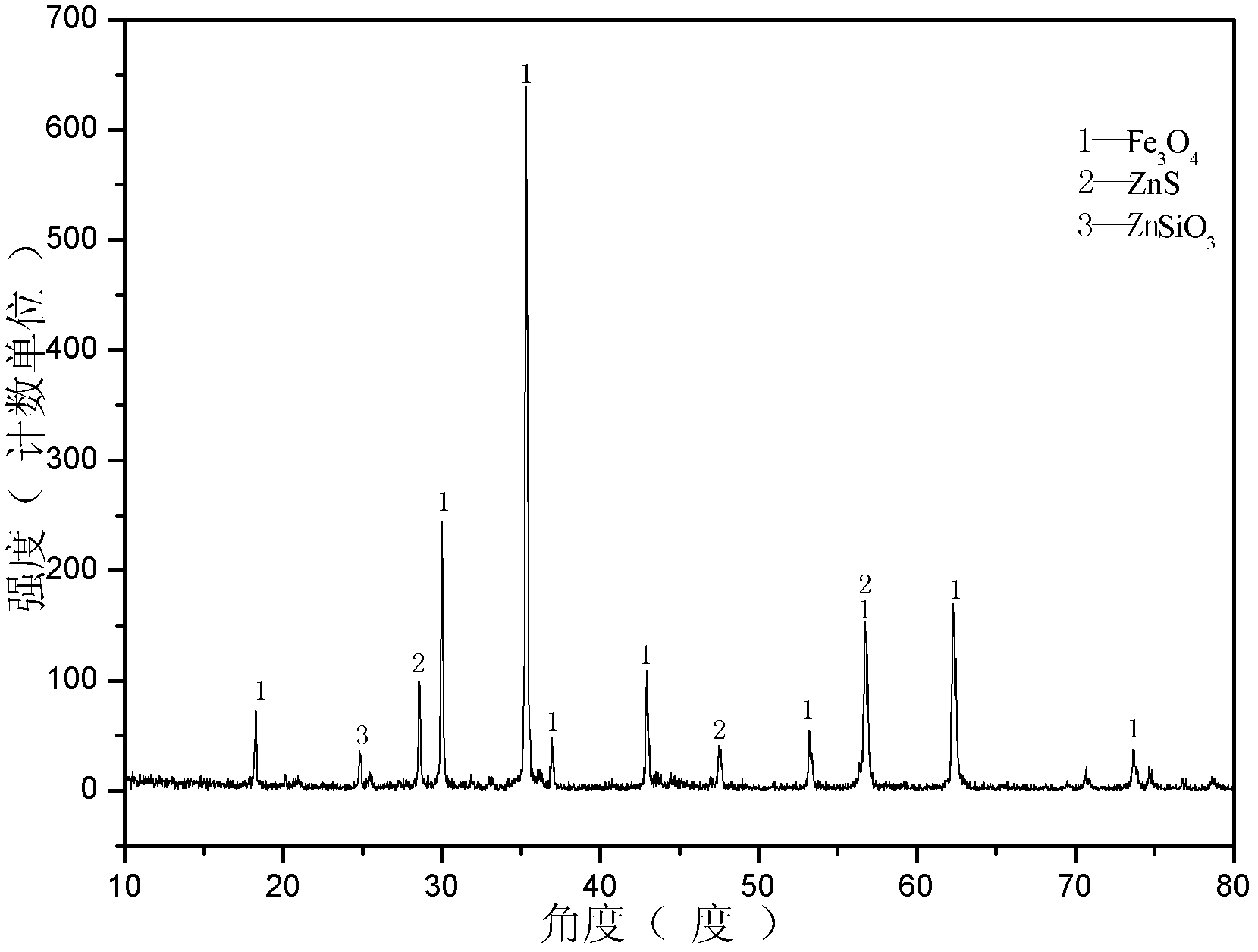

Method for recycling iron in multilevel magnetic separation mode from zinc hydrometallurgy process

A technology of hydrometallurgy and magnetic separation, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as loss of valuable metals, high hardness, and difficulty in recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

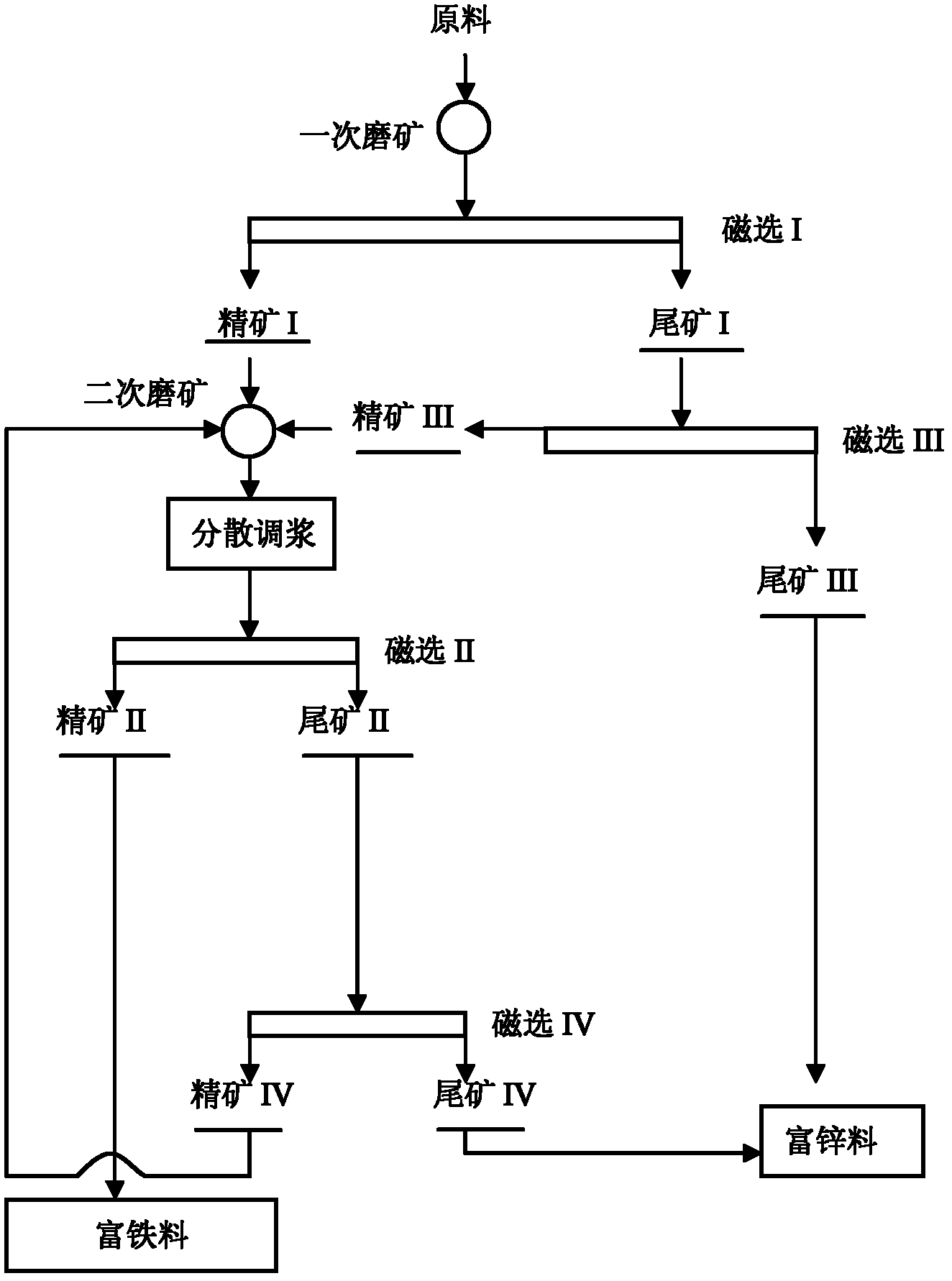

Embodiment 1

[0023] A: According to image 3 According to the technological process, the high-iron zinc calcine reduction roasting product is dried and then added with water to make a slurry, the liquid-solid mass ratio is 20:1, and the speed of the planetary ball mill is controlled as primary ball milling: 250-260r / min, secondary ball milling: 200~220r / min, ball milling time is 10~20min; adjust the magnetic field intensity of Davis magnetic separation tube to magnetic separation I: 0.11~0.12T, magnetic separation II: 0.060~0.065T, magnetic separation III: 0.15~0.16T, Magnetic separation IV: 0.14 ~ 0.15T, the magnetic separation time of magnetic separation I and magnetic separation II is 10min ~ 20min, the magnetic separation time of magnetic separation III and magnetic separation IV is 30 ~ 40min; the dispersant sodium hexametaphosphate The concentration of 5mg / L in the slurry is added; after adding the dispersant, the slurry mixing process is to stir at a speed of 400-800r / min for 10-20m...

Embodiment 2

[0029] A: According to image 3 According to the technical process, the high-iron zinc calcine reduction roasting product is dried and then added with water to make a slurry, the liquid-solid mass ratio is 25:1, and the speed of the planetary ball mill is controlled as primary ball milling: 240-260r / min, secondary ball milling: 200~220r / min, ball milling time is 5~15min; adjust the magnetic field intensity of Davis magnetic separation tube to magnetic separation I: 0.10~0.11T, magnetic separation II: 0.050~0.065T, magnetic separation III: 0.15~0.16T, Magnetic separation IV: 0.14 ~ 0.15T, the magnetic separation time of magnetic separation I and magnetic separation II is 10min ~ 20min, the magnetic separation time of magnetic separation III and magnetic separation IV is 30 ~ 40min; the dispersant sodium hexametaphosphate The concentration of 5mg / L in the slurry is added; after adding the dispersant, the slurry mixing process is to stir at a speed of 400-800r / min for 10-20min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com