Method for cultivating oleaginous microalgae by using fecal sewage

A technology for fecal sewage and oil-producing microalgae, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as energy consumption, reduce costs, save culture water and Reagents, the effect of shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

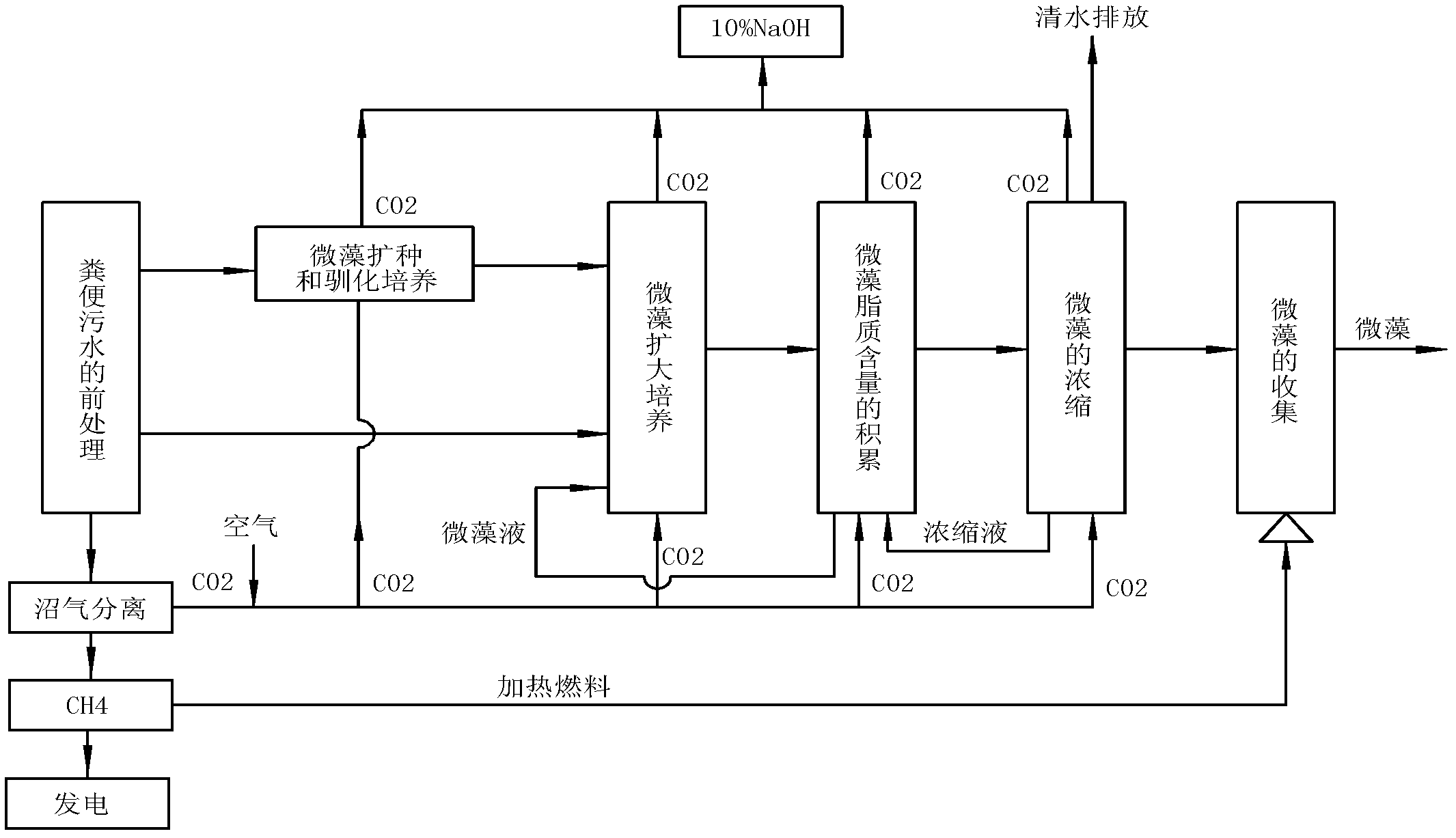

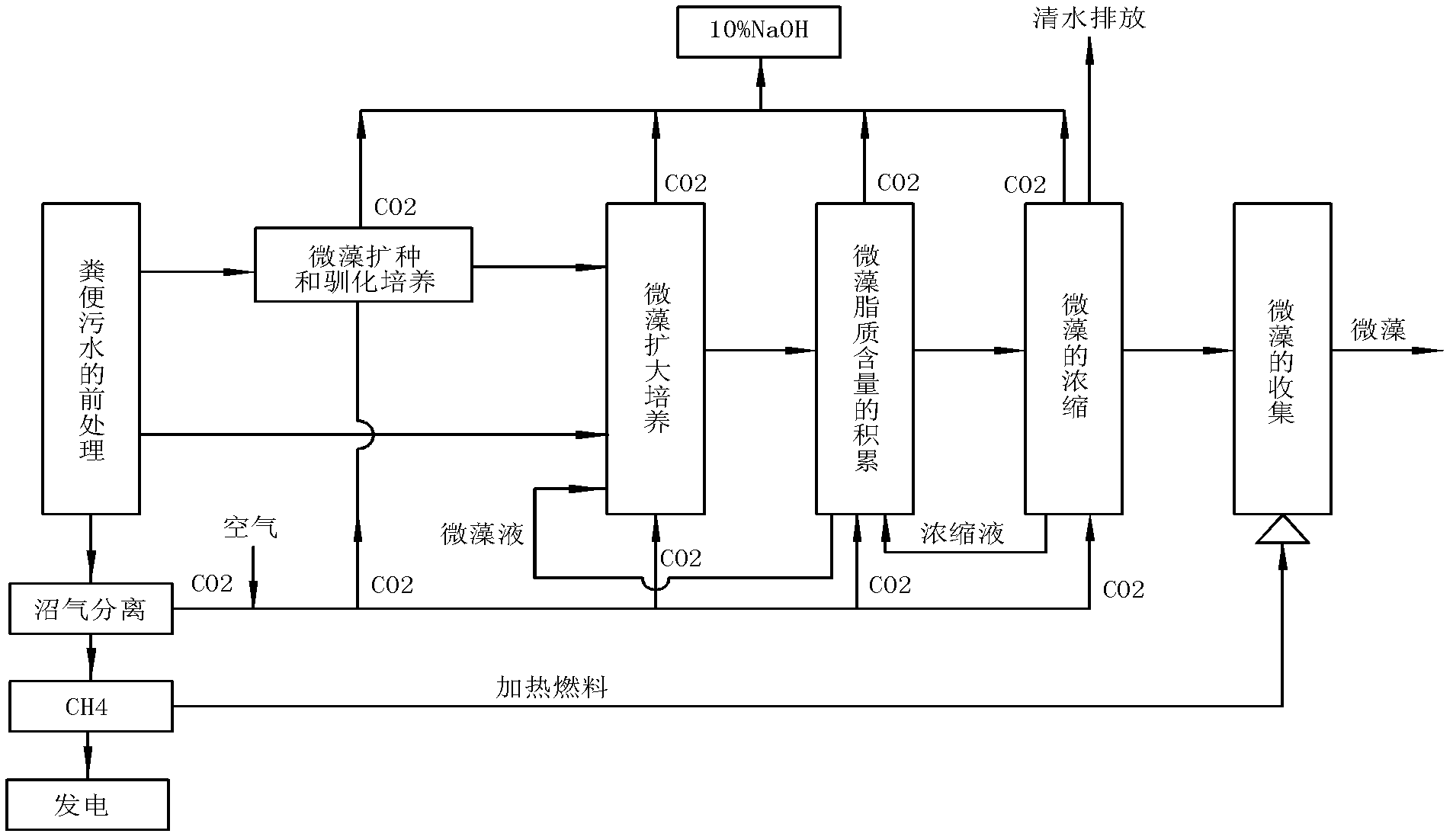

[0028] As shown in the figure, a method for cultivating oil-producing microalgae using fecal sewage according to the present invention includes:

[0029] (1) Pre-treatment of fecal sewage:

[0030] The purpose of this step is to treat the fecal sewage to make it a culture solution suitable for the growth of microalgae. The pre-treatment of the fecal sewage adopts the application of "Beijing Haoye Yisheng Technology Co., Ltd." on September 8, 2009 The title of the invention is "Method for Centralized Treatment of Stool", and the patent number is the method described in ZL 200910092443.7. After solid-liquid separation, flocculation dehydration, aerobic composting, anaerobic treatment, facultative aerobic treatment, aerobic treatment, membrane biological reaction treatment and odor control, the feces and sewage are discharged to the standard. Although the liquid meets the discharge standard, However, because of its high nitrogen and phosphorus content, it cannot be reused. The liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com