Air conditioner cold-hot water unit with antifreeze solution regenerated heat recovery device

A heat recovery device, hot and cold water unit technology, applied in the direction of heating and cooling combination, machines using waste heat, refrigerators, etc., can solve the problems of limited application area, expansion crack damage, huge solution storage space, etc. The effect of frost or icing, increasing the evaporation temperature, and increasing the concentration of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

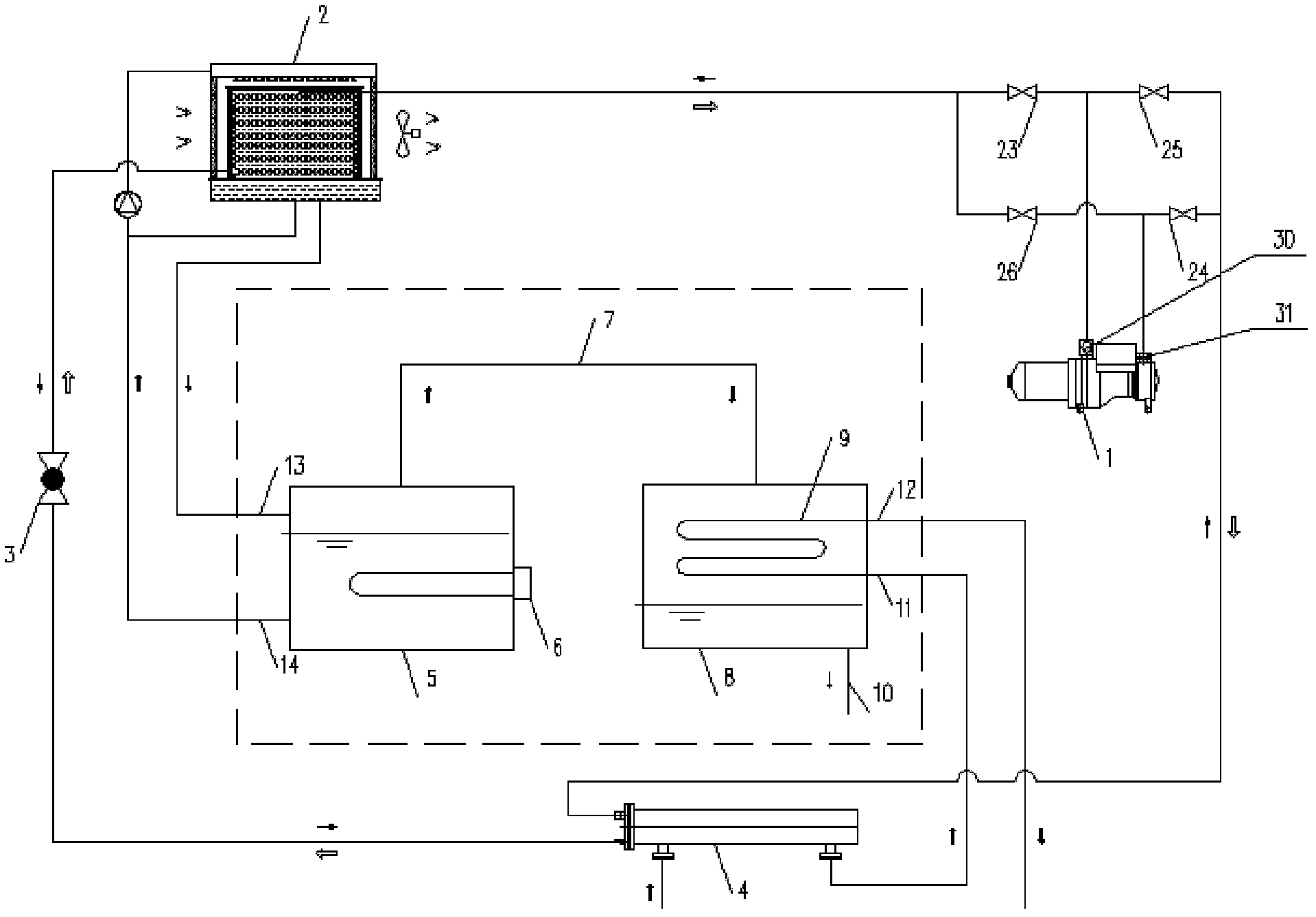

Embodiment 1

[0034] In this embodiment, a kind of air-conditioning cold and hot water unit with antifreeze solution regeneration heat recovery device, such as figure 1 As shown, it includes compressor 1, evaporative condenser 2, throttling device 3, evaporator 4 and antifreeze solution regeneration heat recovery device (as shown inside the dotted box in the figure), and the interfaces at one end of compressor 1 are respectively connected to evaporator The gas pipe of the evaporative condenser 2 and the gas pipe of the evaporator 4, the interface at the other end of the compressor 1 are respectively connected to the gas pipe of the evaporative condenser 2 and the gas pipe of the evaporator 4, and the connecting pipes where the throttling device 3 is located are respectively Connect the liquid pipe of the evaporator and the liquid pipe of the evaporative condenser; the cooling water system of the evaporative condenser is equipped with an antifreeze solution regeneration heat recovery device; ...

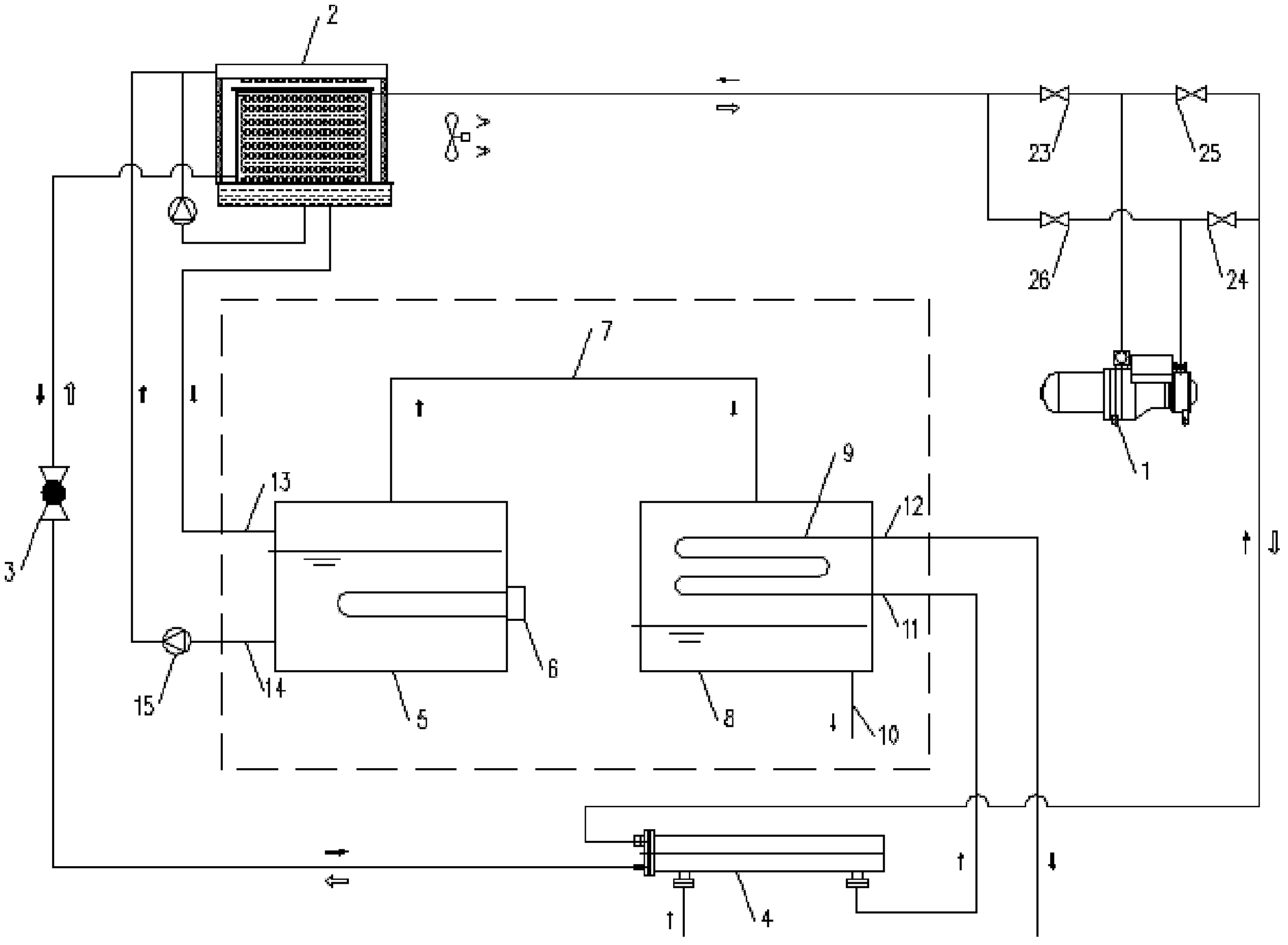

Embodiment 2

[0039] In this embodiment, a kind of air-conditioning cold and hot water unit with antifreeze solution regeneration heat recovery device, such as figure 2 As shown, compared with Embodiment 1, the difference is that a solution pump 15 is provided on the high-concentration antifreeze solution channel 14 .

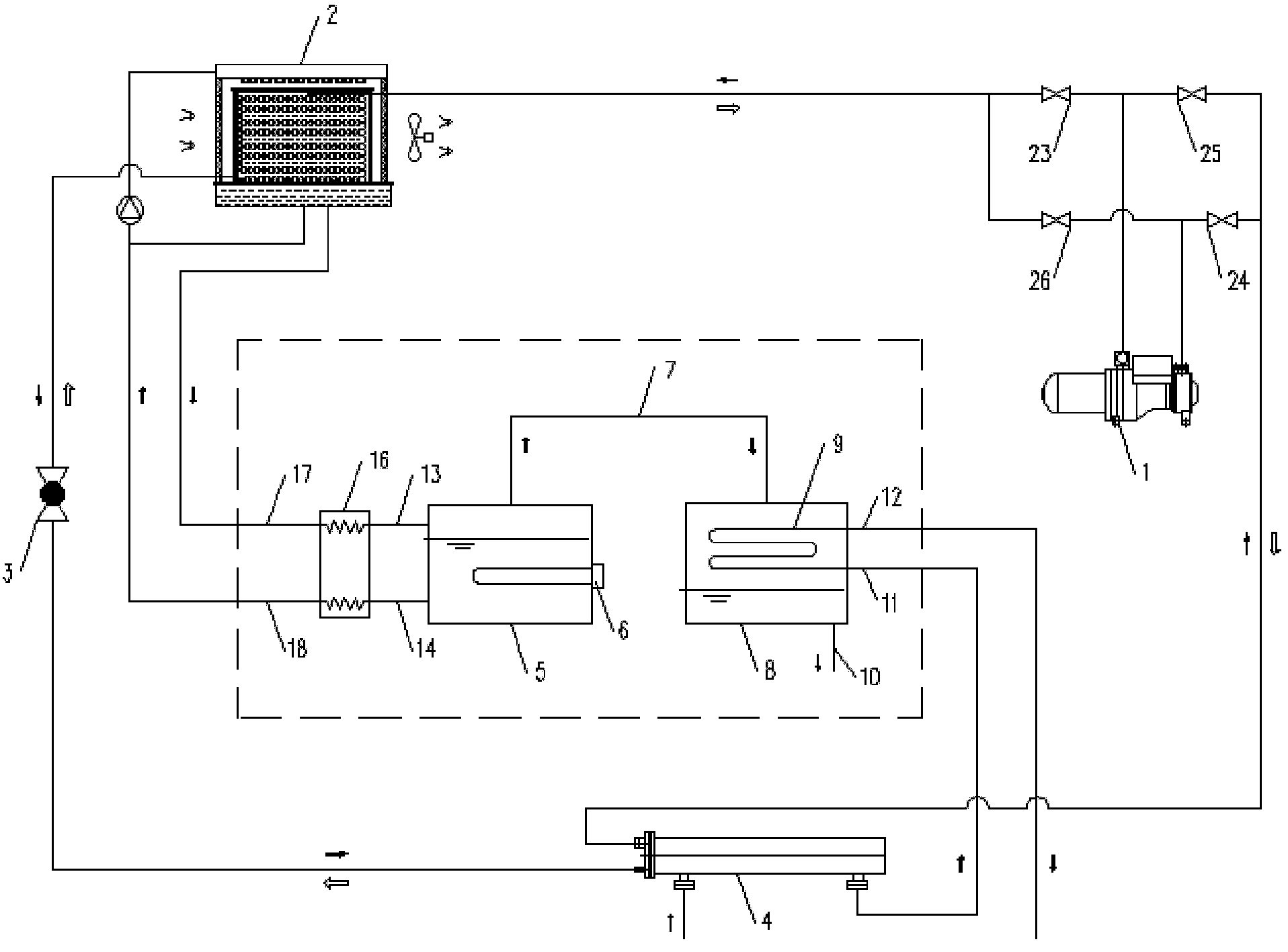

Embodiment 3

[0041] In this embodiment, a kind of air-conditioning cold and hot water unit with antifreeze solution regeneration heat recovery device, such as image 3 As shown, compared with Embodiment 1, the difference is that the antifreeze solution regeneration heat recovery device also includes a second heat exchanger 16, and the second heat exchanger is provided with a low-concentration solution inlet 17 and a high-concentration solution outlet 18 The low-concentration antifreeze solution passage 13 passes through the second heat exchanger 16 and communicates with the low-concentration solution inlet 17 , and the high-concentration antifreeze solution passage 14 passes through the second heat exchanger 16 and communicates with the high-concentration solution outlet 18 . The low-concentration antifreeze solution and the high-concentration antifreeze solution perform primary heat exchange in the second heat exchanger, recovering the sensible heat of the high-concentration antifreeze sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com