Method for testing wettability of electronic-grade glass fiber cloth

A technology of glass fiber cloth and testing method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc. It can solve the problems of good light transmittance, affecting the viscosity of resin or glue, and poor repeatability of test results, so as to achieve good repeatability and external The influence of factors is small, and it is easy to realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A test method for wettability of electronic grade glass fiber cloth, comprising the steps of:

[0026] (1) Prepare mixed reagent: by weight, said mixed reagent includes 95% mixed solvent, 4.9% indicator, and 0.1% auxiliary agent;

[0027] The mixed solvent is selected from 40% ethanol and 55% water; the indicator is selected from 2.9% methylene blue and 2% methylene blue; the auxiliary agent is selected from 0.1% polyethylene glycol 200;

[0028] The surface tension of the mixed reagent is 3.8×10 -2 N / M;

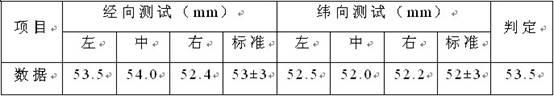

[0029] (2) Select different batches of electronic-grade glass fiber cloth (7628 glass fiber cloth (basis weight: 210±3g / m 2)), drop 0.2mL of the mixed reagent on the surface of the electronic grade glass fiber cloth at a height of 10cm, start timing, measure the diffusion length of the mixed reagent along the warp and weft within 2min, collect more than 25 sets of data and put them into the Minitab15 software Analysis, the operation path is statistics-control char...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com