Immersion control device for lithography machine

A technology of control device and lithography machine, applied in the direction of photolithography exposure device, micro-lithography exposure equipment, etc., can solve the problems of pressure concentration, uneven air flow, and affecting imaging quality, so as to relieve pressure accumulation and pressure distribution Uniform, low-scattering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention more clear, the working principle, structure and specific implementation of the present invention will be further introduced below in conjunction with the accompanying drawings.

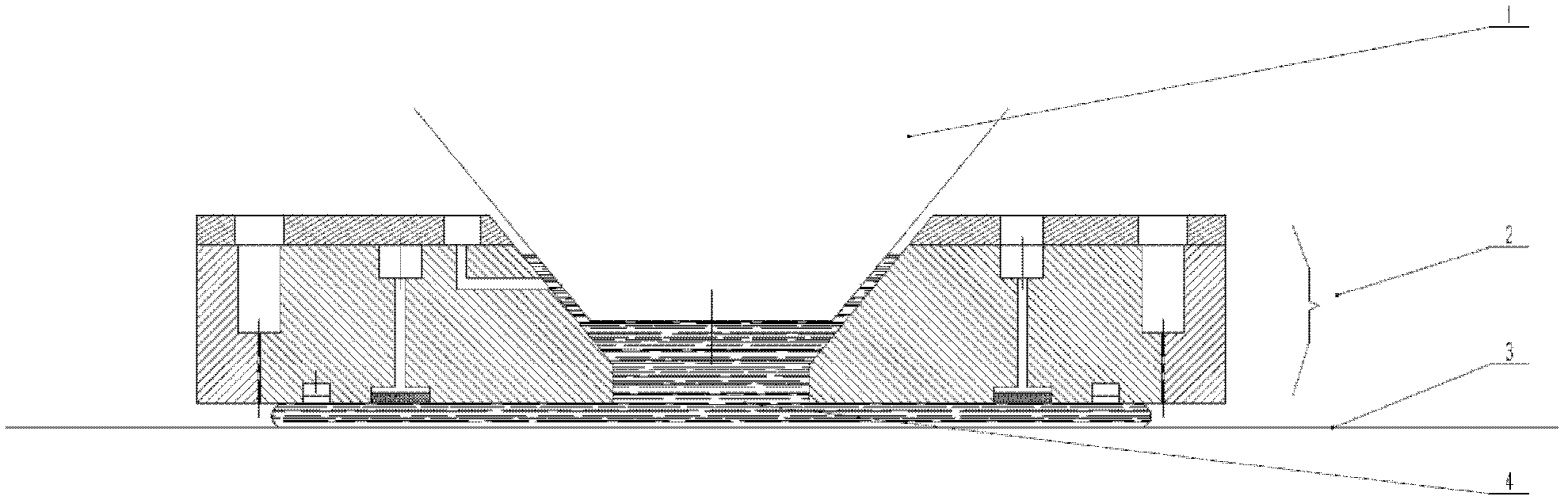

[0020] Such as figure 1 As shown, the assembly of the immersion control device and the end element of the projection lens group according to the embodiment of the present invention is shown. The device can be applied in step-and-repeat or step-and-scan lithography equipment. During the exposure process, the light emitted from the light source, such as: ArF or F2 excimer laser, passes through the aligned mask plate, the end element 1 of the projection lens group and the lens-silicon wafer gap field filled with immersion liquid 4, to the silicon The photoresist on the surface of sheet 3 is exposed.

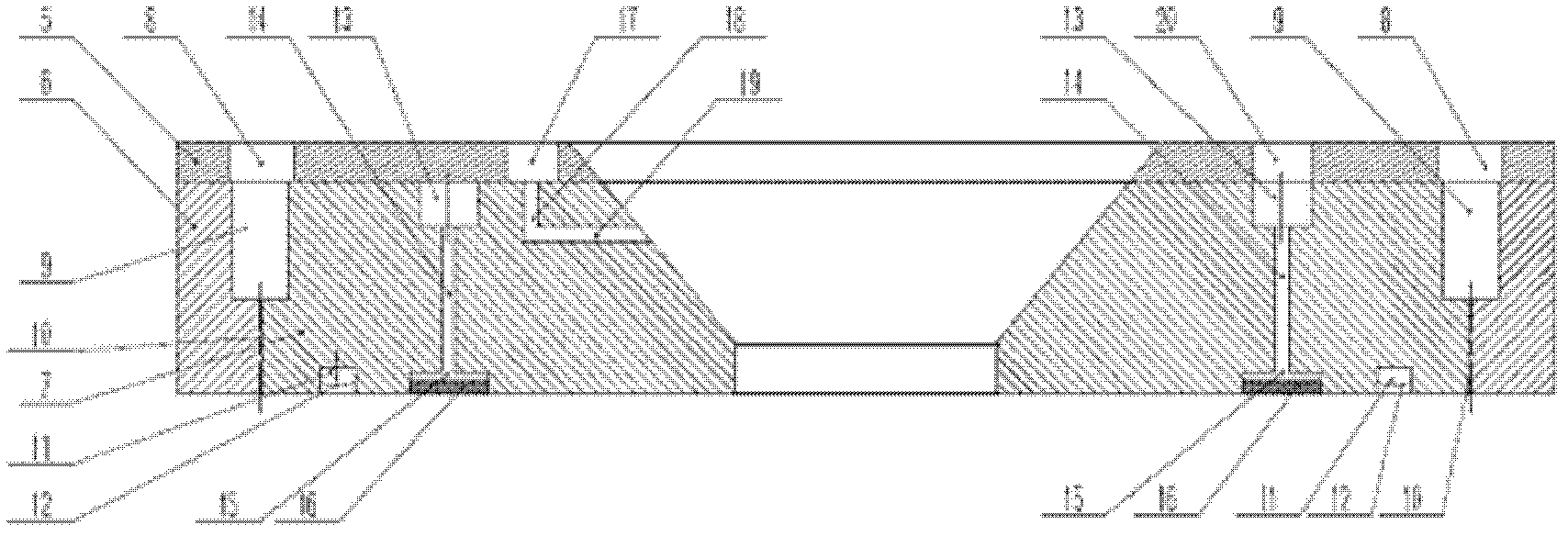

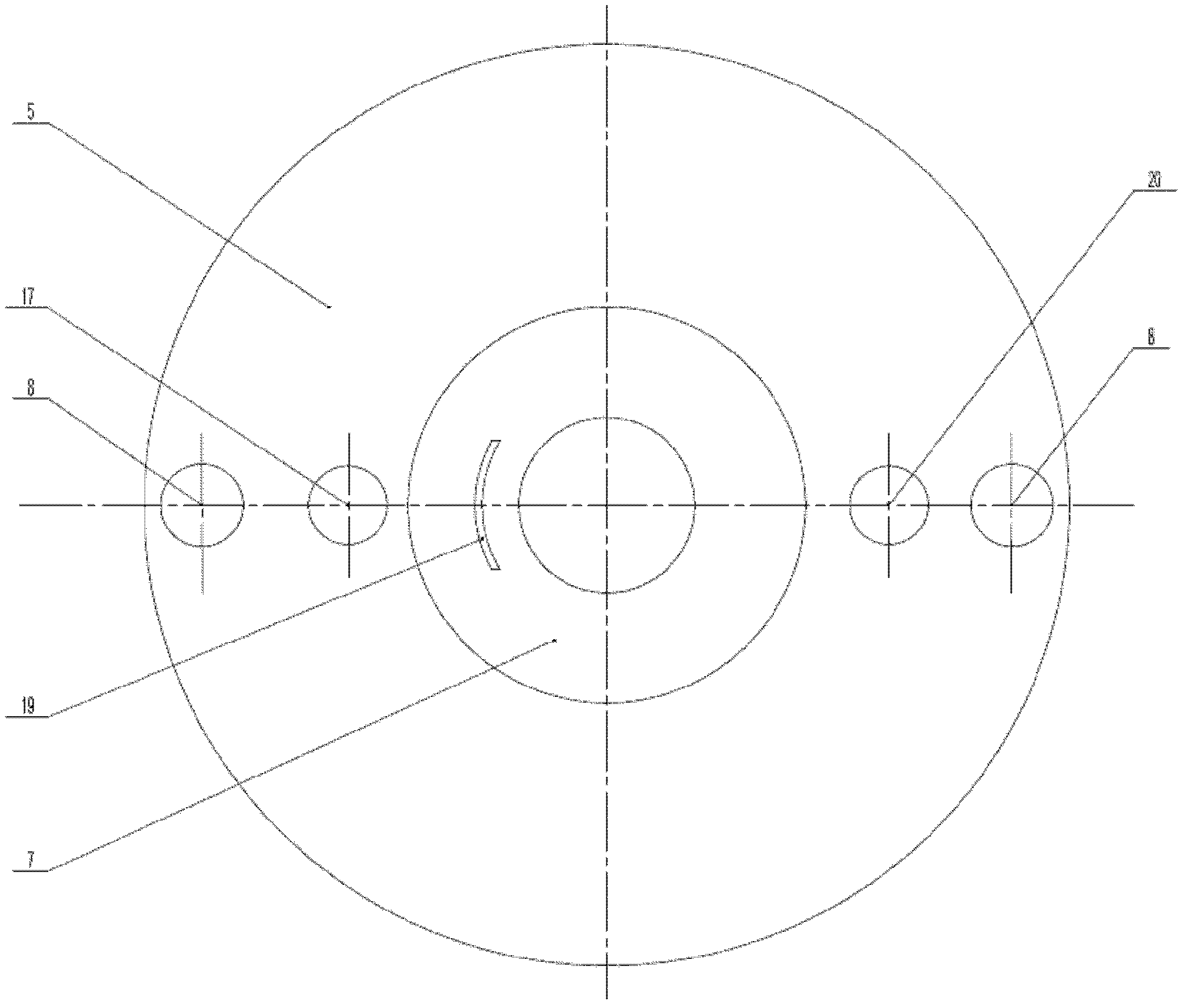

[0021] Such as figure 2 , image 3 , Figure 4 It shows an immersion control device 2 provided between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com