Improved electroconductive glass fiber reinforced plastic electric demister

A conductive glass fiber reinforced plastic and electric mist eliminator technology, applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of affecting the defogging efficiency, large creep, lead poisoning, etc., to improve the defogging efficiency, Shake reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

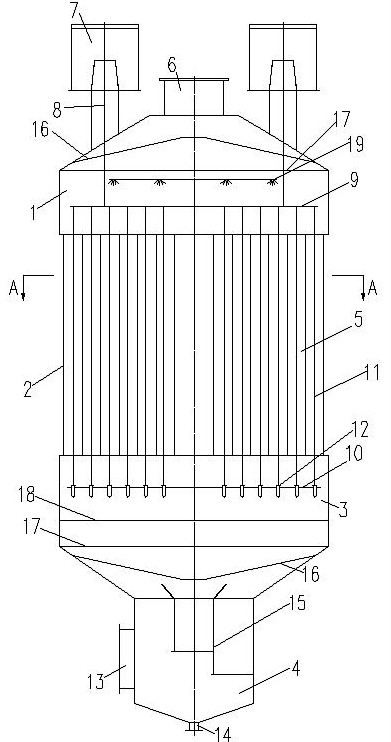

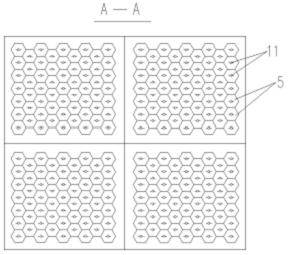

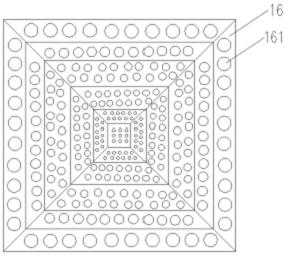

[0025] An improved conductive FRP electrostatic demister, including a shell, which is composed of an upper shell 1, a dust collecting pole chamber 2, a middle shell 3, and a lower shell 4 from top to bottom. The bottom of the upper and middle housings 3 is in the shape of a prism, and the top of the upper housing 1 is provided with an air outlet flange 6, and the upper housing 1 on both sides of the air outlet flange 6 is respectively provided with an insulating insulation box 7, which is insulated. The incubator 7 is provided with a cathode hanger 8, and the cathode hanger 8 is connected to the upper cathode carrying frame 9 in the upper casing 1; the lower cathode carrying frame 10 is arranged in the middle casing 3, and the dust collecting The pole chamber 2 is a tube bundle group formed by a number of anode tubes 5 closely arranged through the shared surface. A cathode line 11 is passed through the center of each anode tube 5. The upper end of each cathode line 11 is laid o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Inscribed circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com