Method and system for preparing butadiene

A technology of butadiene and butadiene, which is applied in the field of preparing butadiene, can solve problems such as butadiene needs to be improved, butadiene production cost is high, and supply risks exist, so as to improve efficiency, safety performance, and industrial applicability The effect of increasing and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

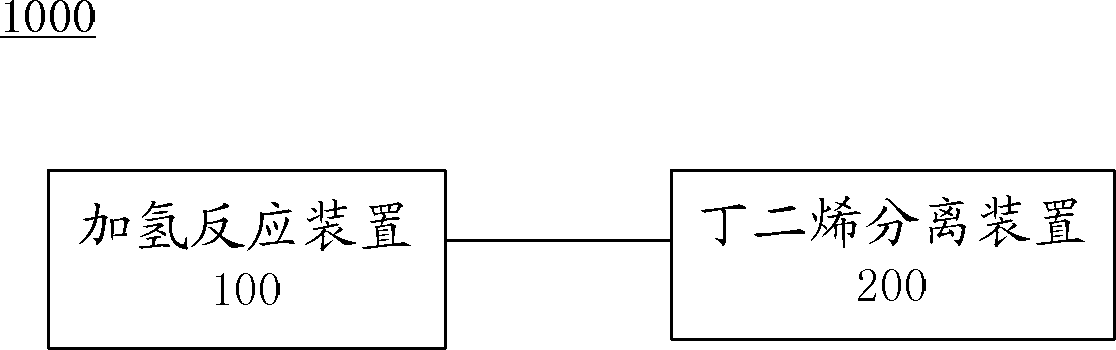

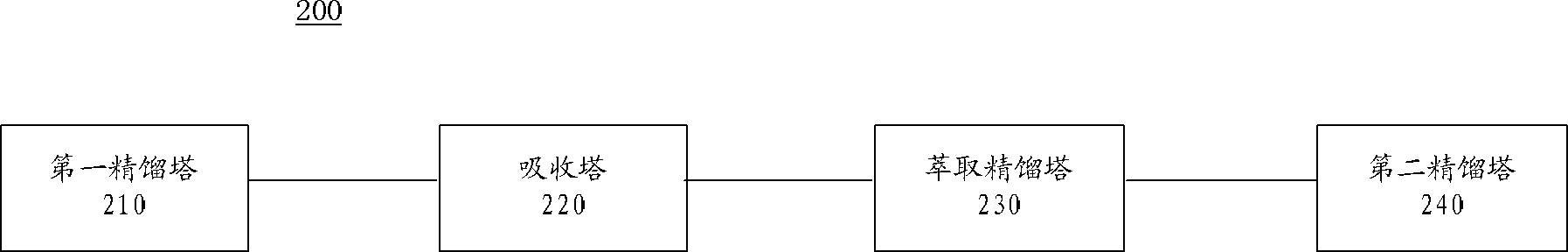

[0040] figure 1 A schematic diagram of the overall system for preparing butadiene employed in Example 1 is shown, figure 2 A schematic diagram of a butadiene separation device according to an embodiment of the present invention is shown.

[0041] Vinyl acetylene was mixed with nitrogen, hydrogen and CO, and the composition of the obtained mixed gas was 29% vinyl acetylene, 40% hydrogen, 30% nitrogen and 1% CO (volume ratio) to obtain hydrogenation reaction raw materials. The hydrogenation reaction raw material enters the fixed-bed reactor (catalyst is 0.1%Pd / Al 2 o 3 , reaction temperature 30°C, normal pressure, vinyl acetylene space velocity 100ml·gcat -1 h -1 ) to carry out hydrogenation reaction, the hydrogenation reaction product gas mixture (the first gas mixture) coming out from the reactor is vinyl acetylene, butadiene, 1-butene, cis 2-butene, trans 2-butene and Butane gas mixture. The hydrogenation reaction product gas mixture (the first gas mixture) is joined i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com