Technology of extractive distillation separation of ethyl acetate-ethanol-water

A technology of ethyl formate and extractive distillation, which is applied in the field of extractive distillation technology, can solve the problems of waste of resources, inability to use ordinary rectification to separate, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

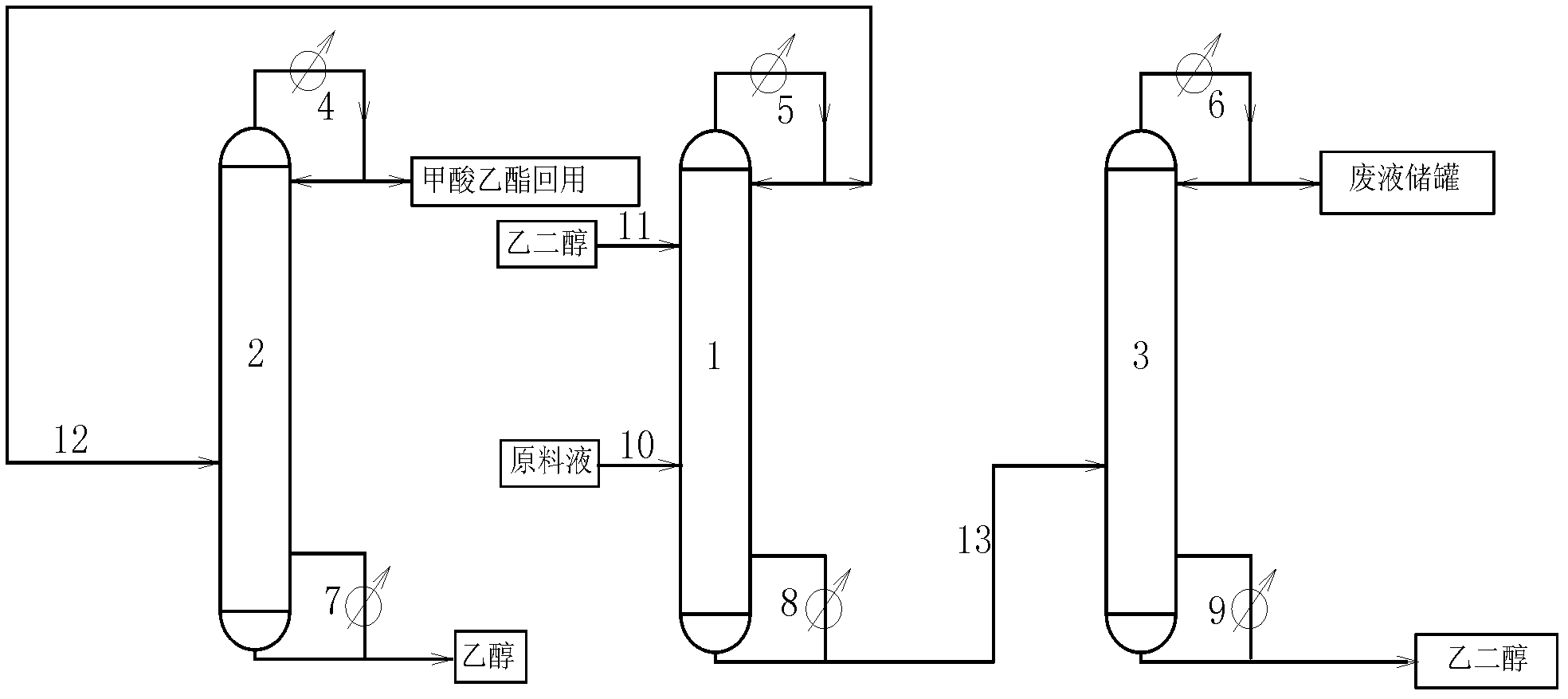

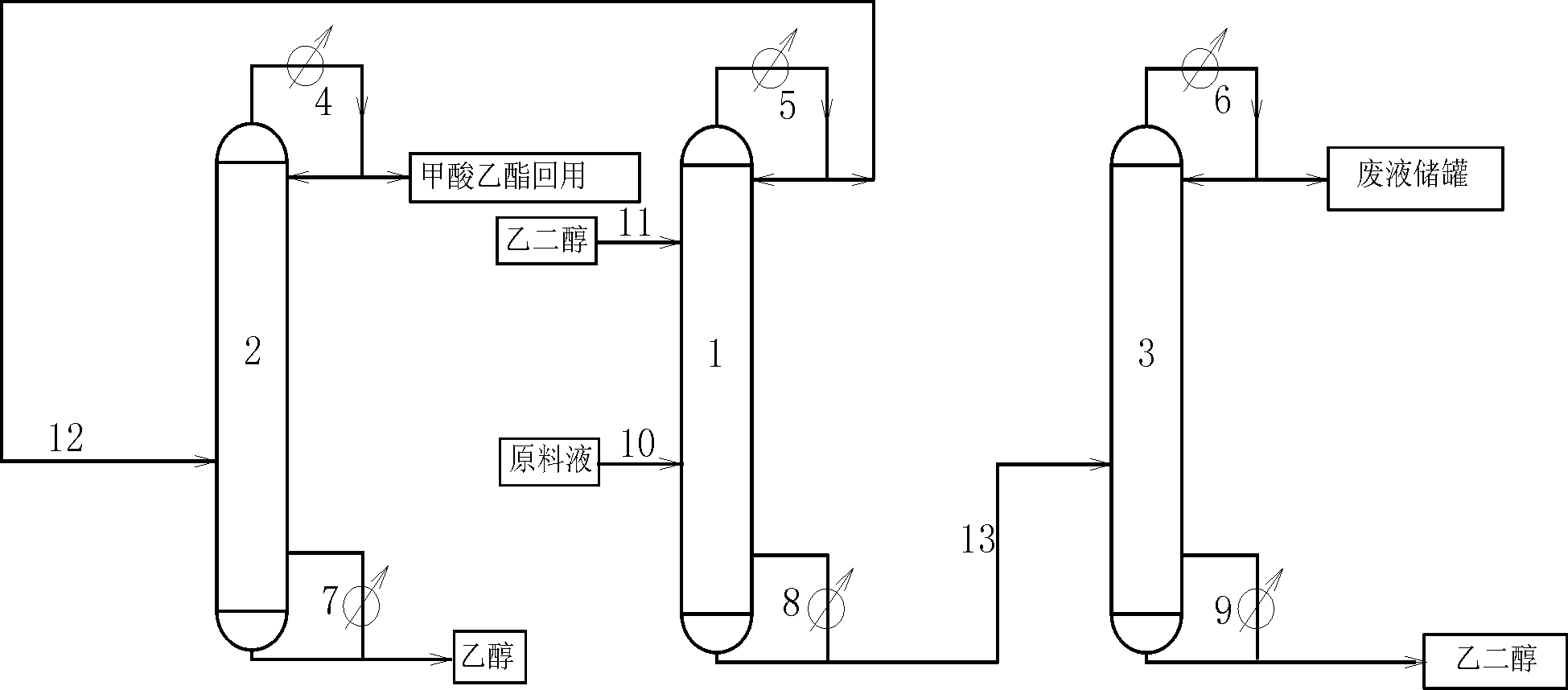

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the number of trays of extractive distillation tower 1 is 45, and tower diameter is 600mm, and operating pressure is 101.325KPa, and the number of trays of ethyl formate recovery tower 2 is 45, and tower diameter is 400mm, and operating pressure is 101.325KPa , the number of trays of the extraction agent recovery tower 3 is 40, the tower diameter is 400mm, and the operating pressure is 12.5KPa.

[0030] The extractant 11 (at a temperature of 30° C.) is continuously added to the extractive distillation column 1 from the 9th tray at a flow rate of 500 kg / h, and the raw material solution 10 (50% ethyl formate (mass fraction, the same below), 40% ethanol , water 10%, temperature 30 DEG C) with the flow rate of 1000kg / h from the 27th plate continuously into the extractive distillation column 1, the steam rising from the top of the extractive distillation column 1 is condensed by the condenser 5 at the top of the extractive distillation column 1 , the operating ...

Embodiment 2

[0034] Embodiment 2: the number of trays of extractive distillation tower 1 is 45, and tower diameter is 800mm, and operating pressure is 101.325KPa, and the number of trays of ethyl formate recovery tower 2 is 45, and tower diameter is 600mm, and operating pressure is 101.325KPa , the number of trays of the extraction agent recovery tower 3 is 40, the tower diameter is 600mm, and the operating pressure is 12.5KPa.

[0035] The extractant 11 (at a temperature of 30° C.) is continuously added to the extractive distillation column 1 from the 9th tray at a flow rate of 1000 kg / h, and the raw material solution 10 (50% ethyl formate (mass fraction, the same below), 40% ethanol , water 10%, temperature 30 DEG C) with the flow rate of 2000kg / h from the 27th plate continuously into the extractive distillation tower 1, the steam rising from the top of the extractive distillation tower 1 is condensed by the condenser 5 at the top of the extractive distillation tower 1 , the operating re...

Embodiment 3

[0039] Embodiment 3: the number of trays of extractive distillation tower 1 is 45, and tower diameter is 600mm, and operating pressure is 101.325KPa, and the number of trays of ethyl formate recovery tower 2 is 45, and tower diameter is 400mm, and operating pressure is 101.325KPa , the number of trays of the extraction agent recovery tower 3 is 40, the tower diameter is 400mm, and the operating pressure is 12.5KPa.

[0040] The extractant 11 (at a temperature of 30° C.) is continuously added to the extractive distillation column 1 from the 9th tray at a flow rate of 500 kg / h, and the raw material solution 10 (50% ethyl formate (mass fraction, the same below), 30% ethanol , water 20%, temperature 30 DEG C) with the flow rate of 1000kg / h from the 27th plate continuously into the extractive distillation column 1, the steam rising from the top of the extractive distillation column 1 is condensed by the condenser 5 at the top of the extractive distillation column 1 , the operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com