Method for growing gem crystals by way of vacuum induction heating and device realizing method

A technology of vacuum induction and crystal growth, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of low quality, small temperature gradient, increased energy consumption, etc., to improve crystal quality, reduce heat conduction, save energy cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Adopt the method described in the present invention to grow Φ100 sapphire crystal

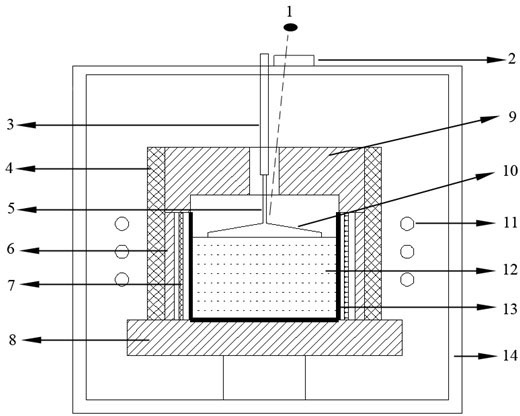

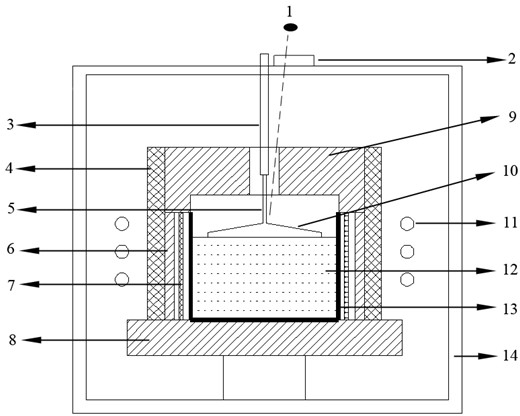

[0021] Aluminum oxide raw material is packed in tungsten, molybdenum or tungsten-molybdenum alloy crucible 13, and press figure 1 The induction heating furnace is installed as shown, in the figure: 1—observation position of human eyes, 2—observation window, 3—seed crystal rod, 4—graphite felt, 5—seed crystal, 6—zirconia barrel, 7—induction tungsten, Molybdenum or tungsten-molybdenum alloy heating body, 8—zirconia support, 9—zirconia insulation cover, 10—crystal, 11—induction coil, 12—melt, 13—tungsten, molybdenum or tungsten-molybdenum alloy crucible, 14—furnace body . Vacuum to a vacuum degree higher than 6×10 -3 Pa, and then start to heat up to melt the raw materials. The direction of the seed crystal is a direction. The traditional Kyropoulos crystal growth process is adopted, and the material surface is observed through the observation window 2. According to the growt...

Embodiment 2

[0022] Embodiment 2: Adopt the method described in the present invention to grow Φ 150 sapphire crystals

[0023] Put the alumina raw material into the tungsten crucible, and press figure 1 The induction heating furnace is installed as shown, in the figure: 1—human eye observation position, 2—observation window, 3—lifting rod, 4—graphite felt, 5—seed crystal, 6—zirconia barrel, 7—tungsten heating body, 8—zirconia holder, 9—zirconia insulation cover, 10—crystal, 11—induction coil, 12—melt, 13—tungsten crucible, 14—furnace body. Vacuum to a vacuum degree higher than 6×10 -3 After Pa, start to heat up to melt the raw material. The direction of the seed crystal is in the c direction. Observe the material surface through the observation window 2. According to the growth rate of the seed crystal, when the seed crystal contacts the liquid surface 5-10 minutes, the seed crystal grows 1-2mm around. Set the seed temperature at a suitable temperature, and then grow crystals at a coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com