Anthocyanin-rich taro rice cake and production method thereof

A technology for anthocyanin and anthocyanin content, applied in application, food preparation, food science, etc., can solve the problems of easy aging, hard rice cake, sticky teeth, etc., reduce hardness, improve nutritional and health value, and improve microstructure and the effect of physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

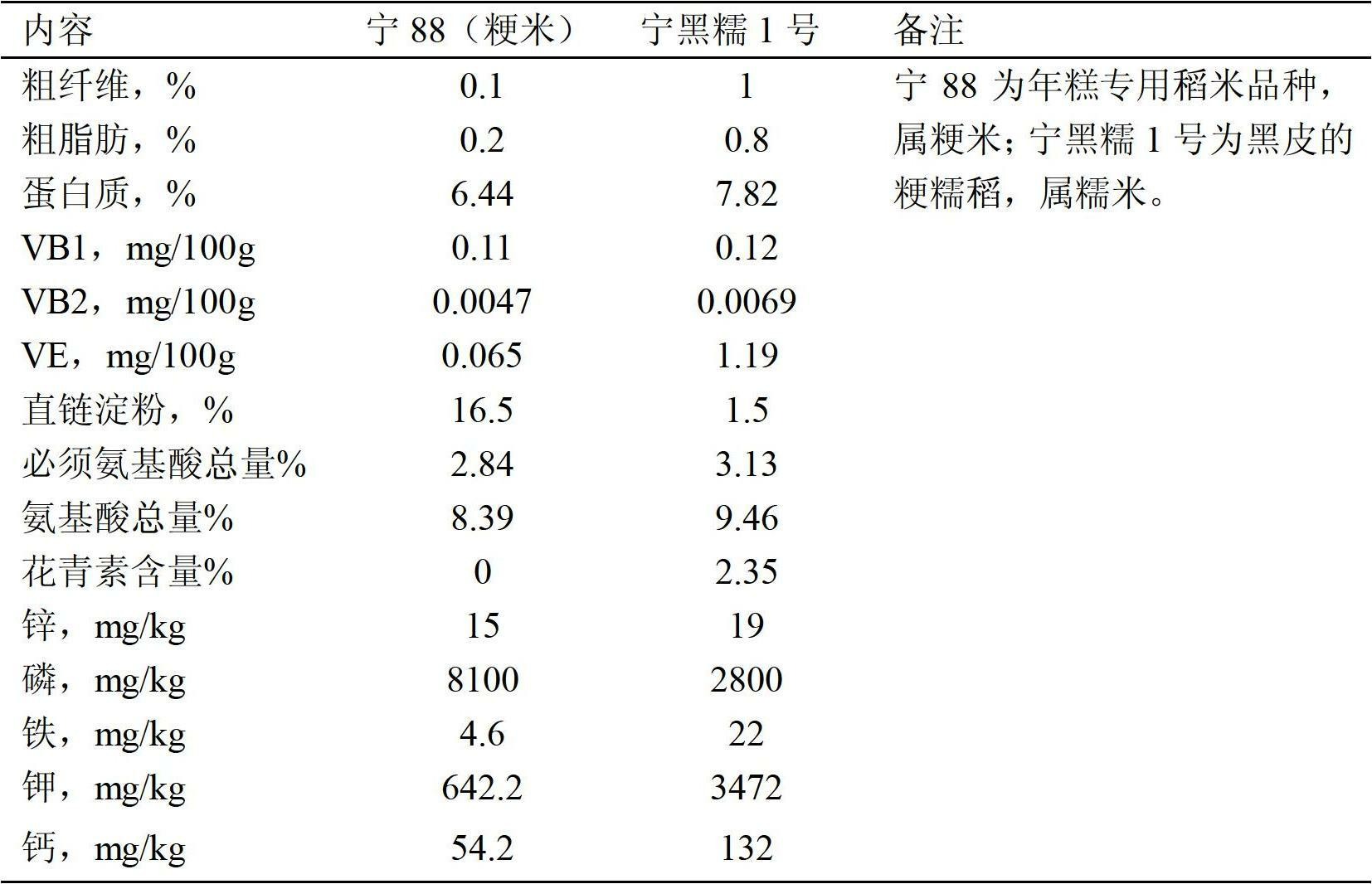

[0037] Choose 75kg of disease-free and normal Fenghua red taro and 50kg of betel nut, wash, peel, coarsely pulverize, colloid mill, high-pressure homogenize, spray-dry, store in bags separately for later use, or mix them.

[0038] Another part of taro whole powder or starch is physically denatured by twin-screw extrusion, superfine pulverization, or chemically modified by cross-linking reaction to obtain denatured starch, and stored in bags for refrigerated use.

[0039] Select 400kg of japonica rice specially used for rice cakes and soak in clean tap water for 24~36h (0~15°C), 100kg of black glutinous brown rice, soak in 5~20μmol / L gibberellin GA3 aqueous solution at 25~30°C for 2h in advance, pick up and drain Germinate in a culture container at 30°C±1°C for 20~30h, and then use a conveyor belt to convey, rinse, mix, water mill, pump slurry, press filter and drain, unload powder blocks, and evenly pour the above taro powder and modified starch , Use a conveyor to transport to ...

example 2

[0043] Select 100 kg of disease-free and normal Fenghua red taro, wash, peel, coarsely pulverize, finely pulverize with a colloid mill, homogenize under high pressure, spray dry, store in bags and refrigerate for later use. In addition, get part of taro whole powder or starch, and adopt the method of example 1 to obtain modified starch for subsequent use.

[0044] Select 400kg of japonica rice for rice cakes, store in stainless steel barrels, wash with clean tap water, soak the rice over the top of the barrel for 24h~36h (0~15°C), and 100kg of black glutinous brown rice, use the method of Example 1 to germinate for 20~30h, and then Wash together on the conveyor belt, send to the starch mill, pump slurry, press filter and drain, unload the powder block, pour the above-mentioned taro powder and modified starch evenly, send it to the loose powder machine with the conveyor belt, and mix the loose powder evenly.

[0045] Put the mixed taro rice flour into the steamer, steam it with...

example 3

[0048] Select 125kg of disease-free normal areca nuts, wash, peel, coarsely pulverize, finely pulverize with a colloid mill, homogenize under high pressure, spray dry, store in bags and refrigerate for future use. Simultaneously adopt the method for example 1 to obtain modified starch for subsequent use.

[0049] Select 500kg of japonica rice for rice cakes, store it in a stainless steel bucket, wash it with clean tap water, soak the rice over the top of the bucket for 24h~30h (0~15℃), water mill, pump slurry, press filter and drain, unload the powder block, and pour it evenly Mix the above-mentioned taro powder and pine powder.

[0050] Put the mixed taro rice flour into the steamer, steam it with boiler water steam (10~15min), pour it into the rice cake machine, extrude, cut, cool, bag, vacuum pack, sterilize, and box.

[0051] The rice cake produced has the unique fragrance of taro, good lightness and beautiful color. Moderate hardness, non-sticky, good taste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com