Bead chain manganese borate Mn2BO3 one-dimensional nano-fiber and preparation method thereof

A technology of nanofibers and fibers, applied in the field of manganese borate Mn2OBO3 one-dimensional nanomaterials and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

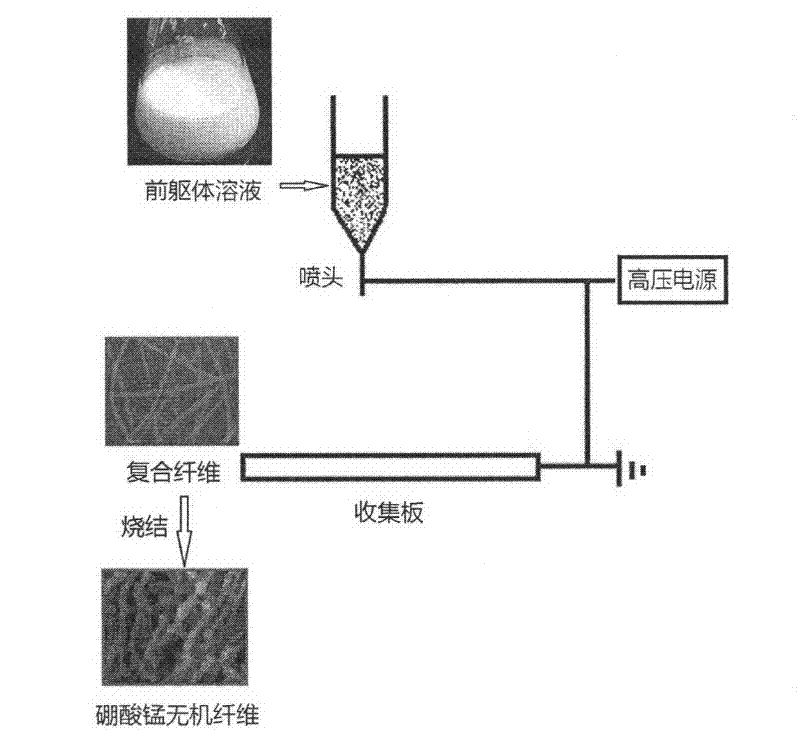

[0017] 1. Prepare the precursor electrospinning solution, use manganese acetate as the manganese source, boric acid as the boron source, polymer polyvinylpyrrolidone (PVP) as the complex, and absolute ethanol as the solvent, and the mixed solution is stirred by magnetic force After more than 10h, static aging, waiting for electrospinning.

[0018] 2. Conduct electrospinning. Take the electrospinning precursor solution and add it to the spinner made of glass syringe. The injection needle (0.8mm inner diameter) is used as the spinning nozzle, the electrospinning voltage is 12kV, and the vertical distance between the nozzle and the collecting plate is 10cm. A white non-woven fabric-like PVP / [Mn(CH 3 COO) 2 +H 3 BO 3 ] The composite fiber membrane was dried at 80°C.

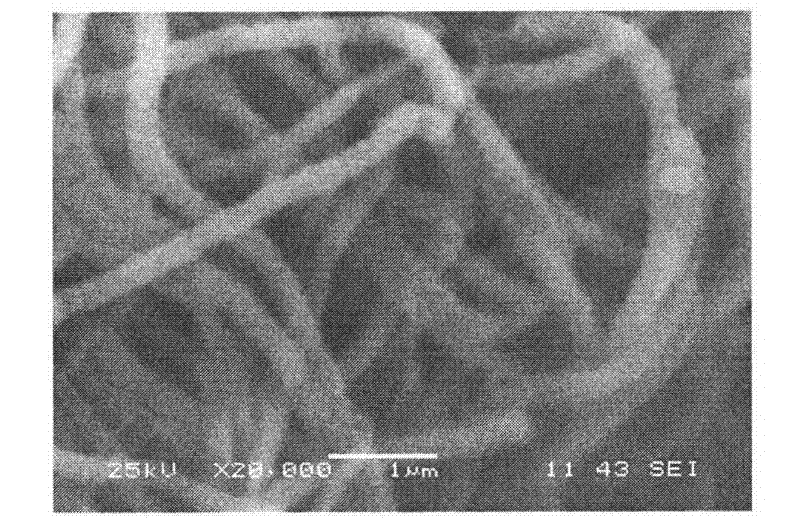

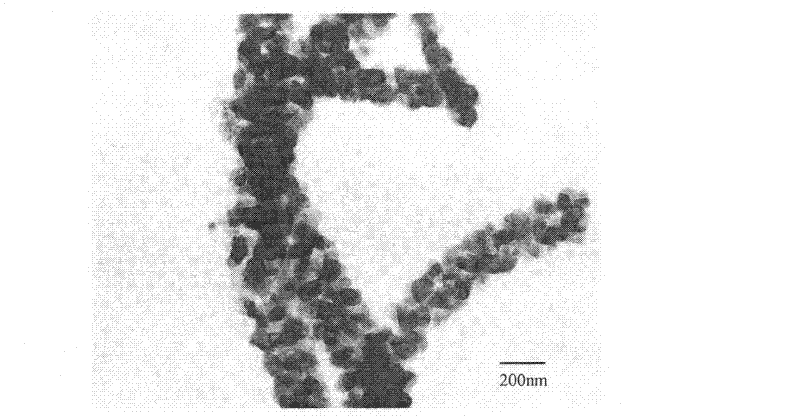

[0019] 3. Heat treatment. Put the electrospun composite fibers into a crucible and sinter in a muffle furnace to remove organic components and residual solvents to obtain an inorganic phase. The heating rate is...

Embodiment 2

[0021] 1. Prepare the precursor electrospinning solution, use manganese acetate as the manganese source, boric acid as the boron source, polymer polyvinylpyrrolidone (PVP) as the complex, and absolute ethanol as the solvent, and the mixed solution is stirred by magnetic force After more than 10h, static aging, waiting for electrospinning.

[0022]2. Conduct electrospinning. Take the electrospinning precursor solution and add it to the spinner made of glass syringe. The injection needle (0.8mm inner diameter) is used as the spinning nozzle, the electrospinning voltage is 12kV, and the vertical distance between the nozzle and the collecting plate is 10cm. A white non-woven fabric-like PVP / [Mn(CH 3 COO) 2 +H 3 BO 3 ] The composite fiber membrane was dried at 80°C.

[0023] 3. Heat treatment. Put the electrospun composite fibers into a crucible and sinter in a muffle furnace to remove organic components and residual solvents to obtain an inorganic phase. Stay at a constant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com