Process for recycling and processing hyperhaline reverse osmosis concentrated water

A technology of reverse osmosis concentrated water and treatment process, applied in the field of sewage treatment, can solve the problems of sludge bulking, low purification efficiency, large amount of excess sludge, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Indicators of high-salt reverse osmosis concentrated water to be treated: pH value is 8.6, COD value is 207mg / L, dissolved organic carbon DOC value is 41.6mg / L, total dissolved solids TDS value is 3180mg / L, chromaticity value is 172 (Pt-Co). 5 liters of treated water.

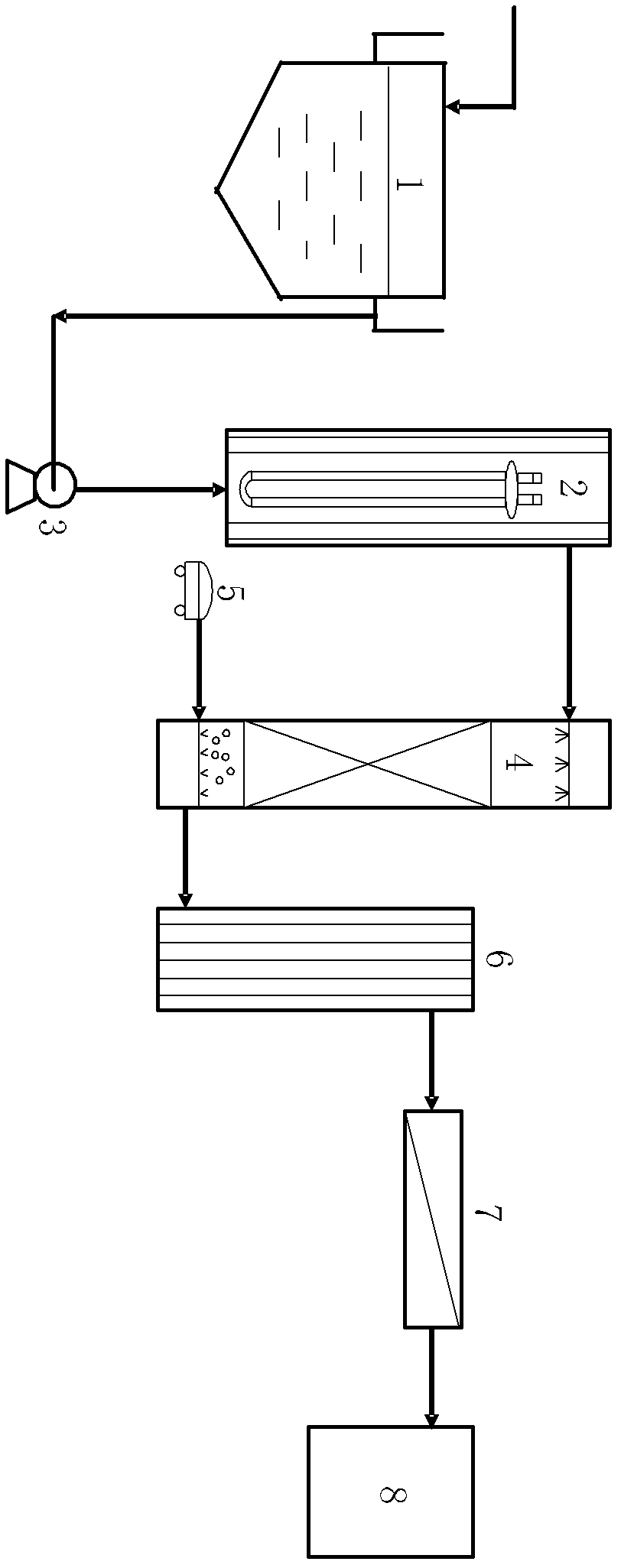

[0031] like figure 1 As shown, the following steps are adopted to reuse the above-mentioned high-salt reverse osmosis concentrated water:

[0032] 1. The high-salt reverse osmosis concentrated water first enters the regulating tank to adjust the water volume, so as to ensure that the whole device can continuously enter water and operate stably. The volume of the adjustment tank is 10 liters. The regulating pool is used to adjust the water intake to ensure continuous water intake and stable operation of the device.

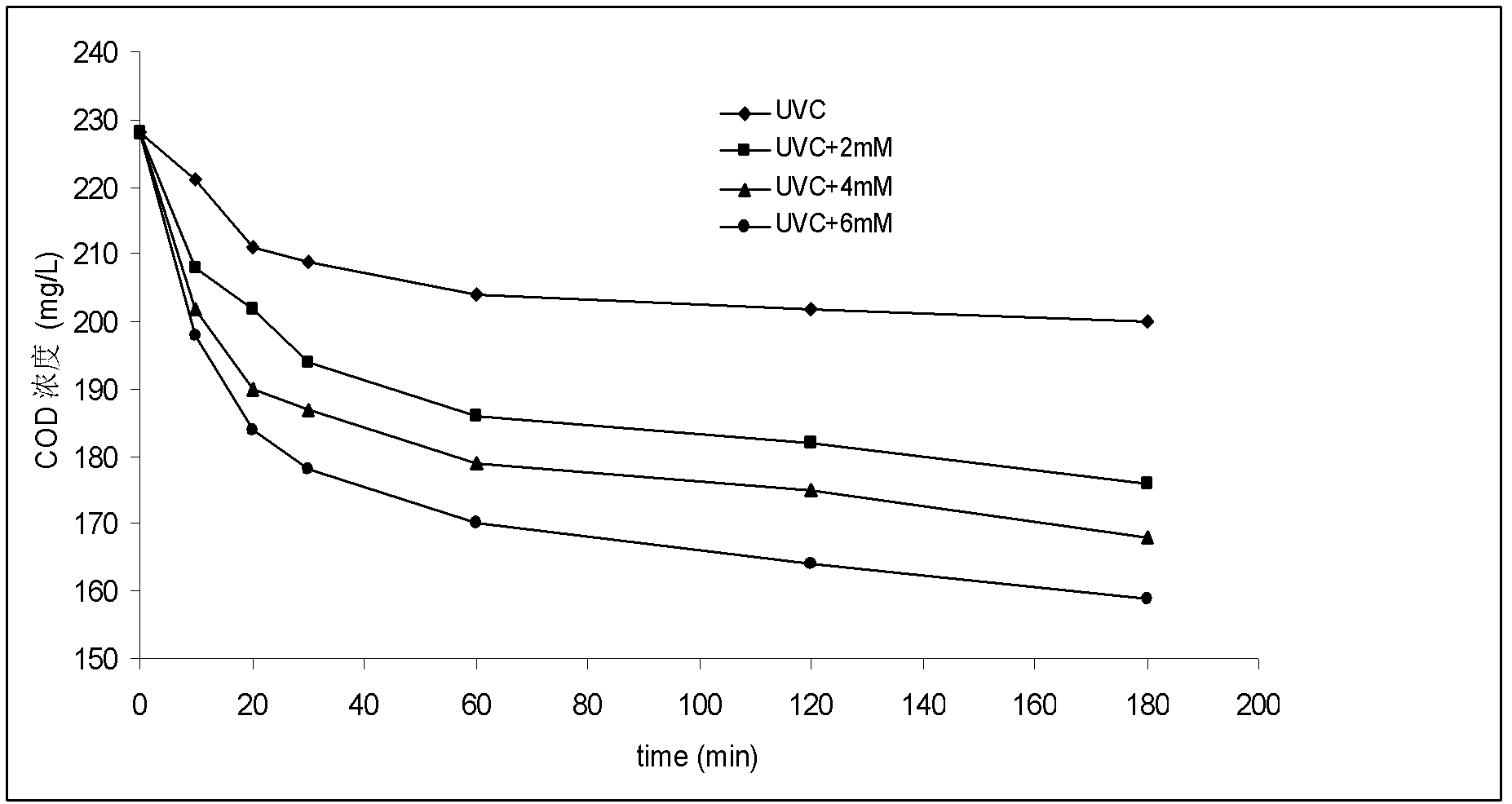

[0033] 2. The effluent from the adjustment pool is pumped into the photocatalytic oxidation reactor by a peristaltic pump, and a photocatalytic oxidant H with a concentration of 50% is ad...

Embodiment 2

[0043] Embodiment 2: except following difference, other is the same as embodiment 1.

[0044] 2. Add photocatalytic oxidant H 2 o 2 0.408mg, UV photolysis reaction 60min.

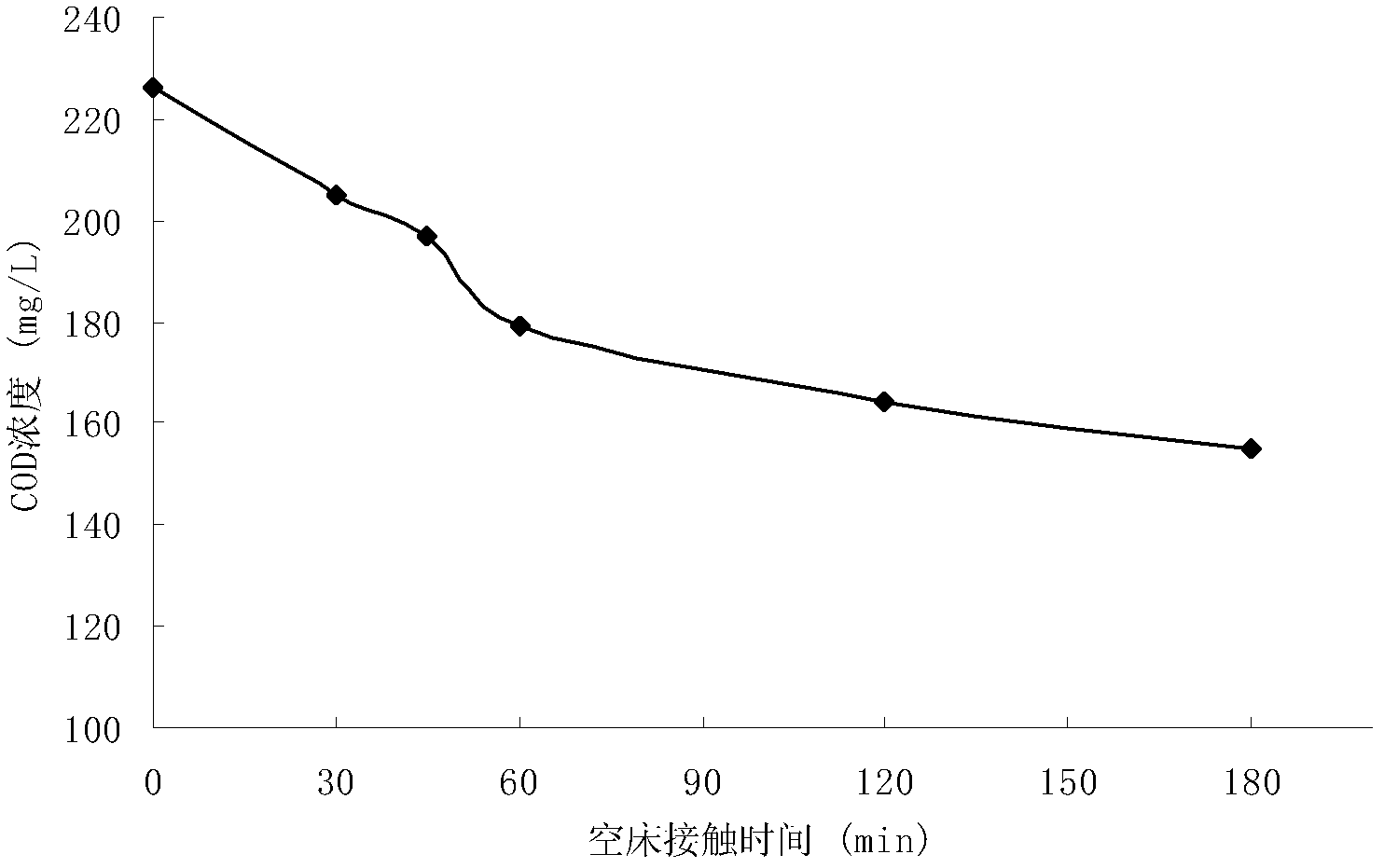

[0045] 3. The empty bed contact time of the biological activated carbon reactor is 180min.

[0046] After testing, the final effluent indicators are: pH value is 8.45, COD value is 18.3mg / L, dissolved organic carbon DOC value is 2.37mg / L, total dissolved solids TDS value is 482mg / L, chromaticity value is 29 ( Pt-Co). The COD removal rate is 91.2%, the TDS removal rate is 84.8%, and the DOC removal rate is 94.3%.

Embodiment 3

[0047] Embodiment 3: except following difference, other is with embodiment 1.

[0048] 2. Add photocatalytic oxidant H 2 o 2 0.272mg, UV photolysis reaction for 30min.

[0049] 3. The empty bed contact time of the biological activated carbon reactor is 60 minutes.

[0050] After testing, the final effluent indicators are: pH value is 8.46, COD value is 19.8mg / L, dissolved organic carbon DOC value is 2.87mg / L, total dissolved solids TDS value is 610mg / L, chromaticity value is 37 ( Pt-Co). The COD removal rate is 90.4%, the TDS removal rate is 80.8%, and the DOC removal rate is 93.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chroma value | aaaaa | aaaaa |

| Chroma value | aaaaa | aaaaa |

| Chroma value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com