Process method for preparing palletized blast-furnace titanium slag into active slag powder

A technology of active slag powder and process method, applied in cement production and other directions, can solve problems such as poor fluidity and thickening of titanium slag, and achieve the effects of low energy consumption, small investment and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

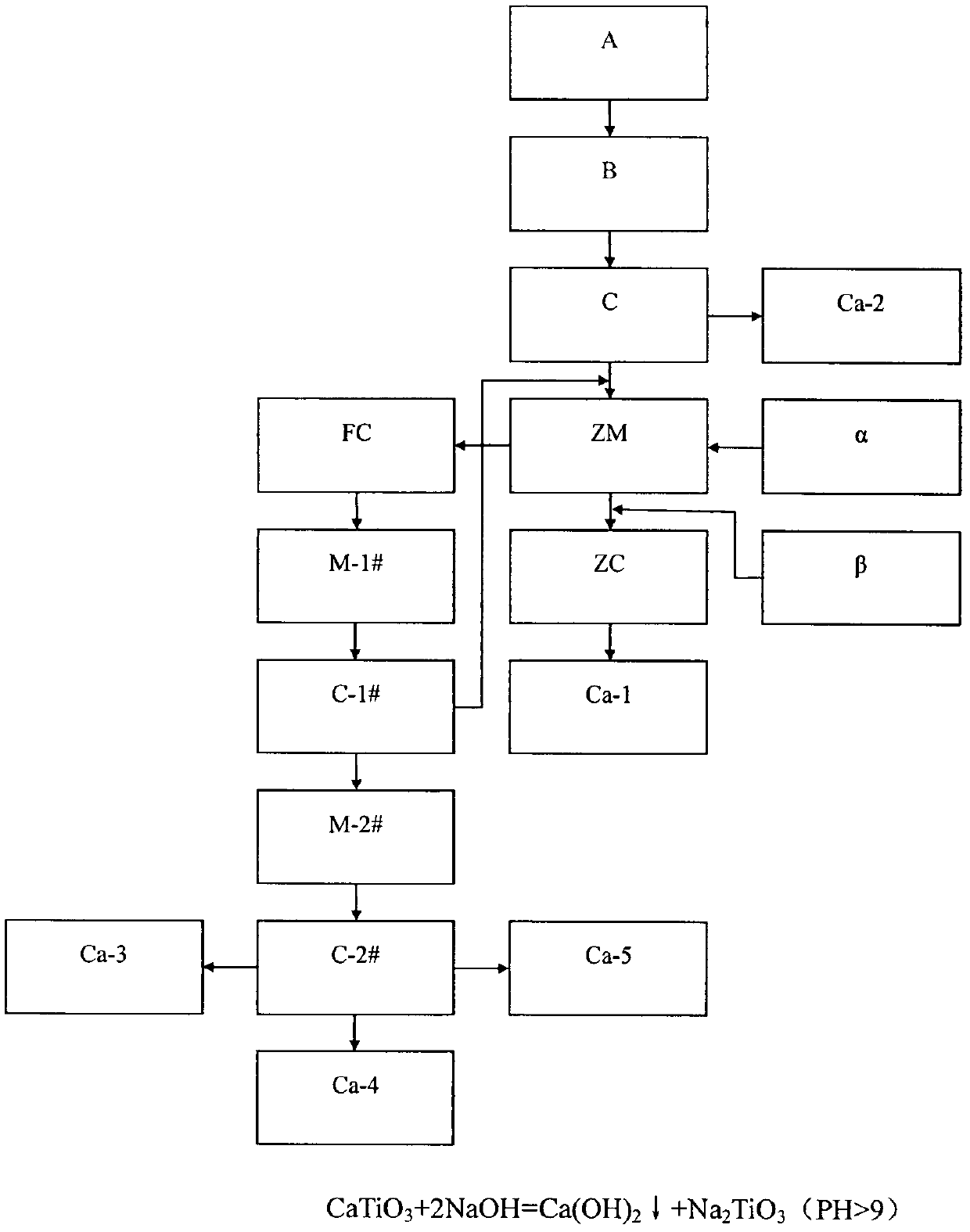

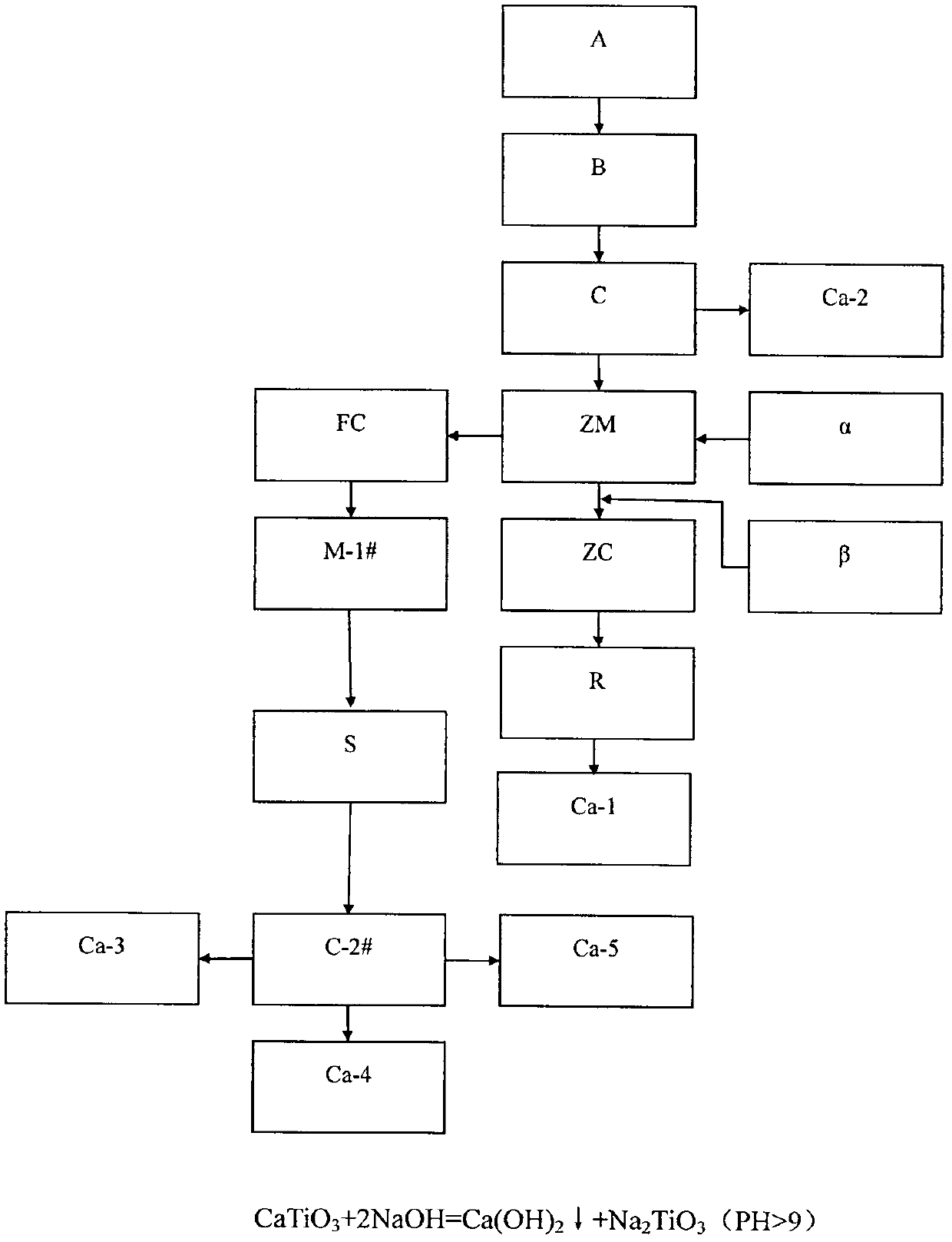

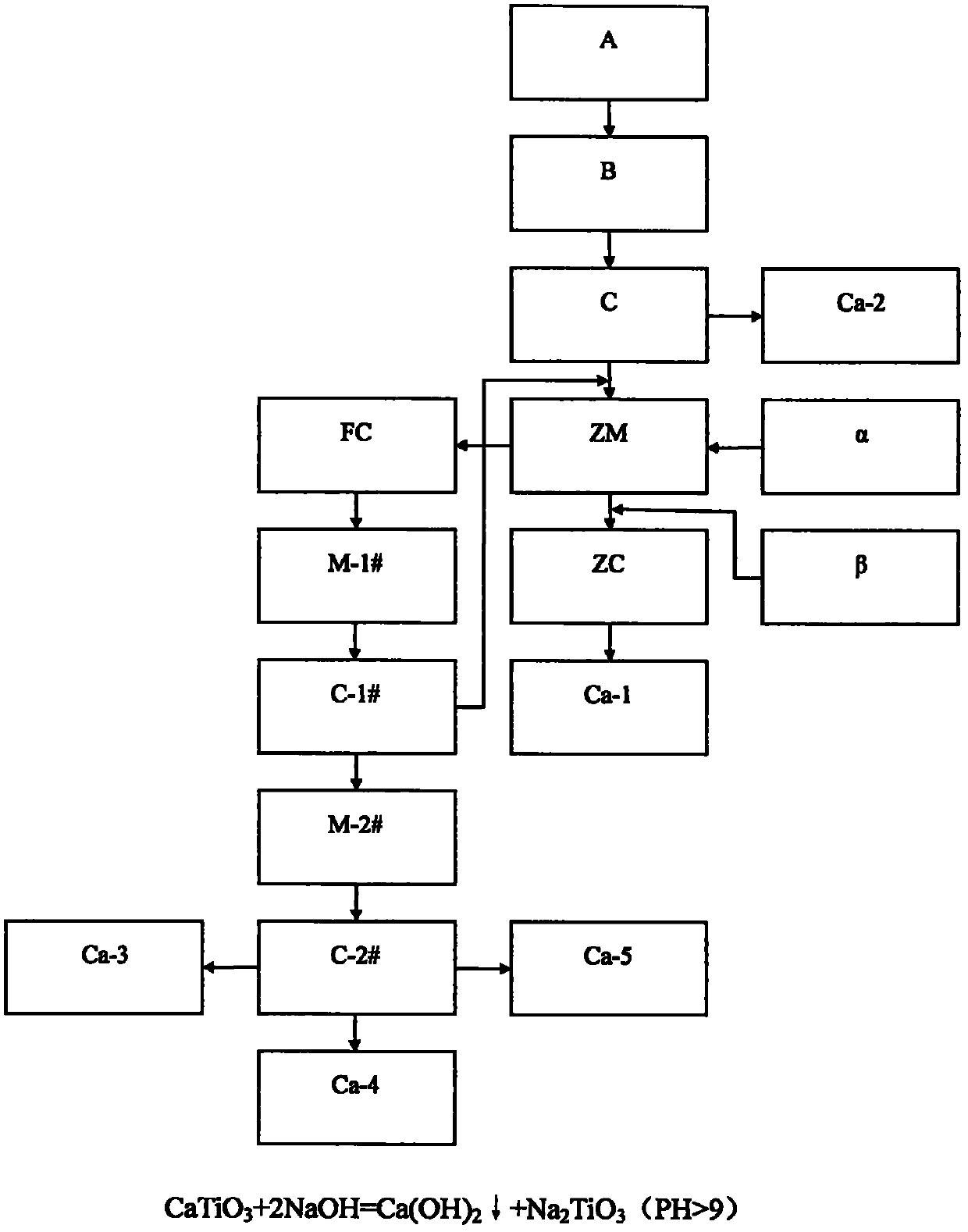

[0053] See figure 1 , a kind of processing method that granulated blast furnace titanium slag is made active slag powder, the processing steps of this method are as follows:

[0054] 1. A raw ore pretreatment section:

[0055] Mix the materials evenly, TiO 2 The content is kept at 10-13% to facilitate smooth production.

[0056] 2. B dehydration section:

[0057] The method of combining air-drying and drying is adopted. When drying, the temperature control range of the material itself is not greater than 600-650°C, and the moisture content of the material is controlled at Mt=-15%.

[0058] 3. C classification iron removal and crushing section:

[0059] The materials with qualified moisture are screened with φ30mm or 30mm×30mm grading sieve. After grading, iron is removed from the material on and off the sieve at the same time, and the material on the sieve is crushed to -30mm after iron removal, and enters the main mill ZM together with the material under the grading siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com