Method for preparing SiO2 aerogel heat insulating composite through adhesive slip casting

A technology of silicon dioxide and composite materials, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of restricting the large-scale popularization and application of bulk aerogel, high cost of aerogel preparation, and harsh condition control requirements. Excellent mechanical properties and mechanical properties, low cost, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of silica alcohol gel

[0029] Mix 10.38g ethyl orthosilicate, 5.34g methyltriethoxysilane, 5.40g deionized water, 34.5g absolute ethanol and 1.83g DMF (molar ratio 1:0.6:6:15:0.5) and stir Evenly, add hydrochloric acid to adjust the pH value to 3.5, stir and catalyze the hydrolysis reaction at room temperature for 24 hours, then add ammonia water to adjust the pH value to 6.5, continue to stir for 10 minutes and then stand still to obtain SiO 2 alcohol gel. SiO will be obtained 2 The alcohol gel was placed in a mixed solution of ethyl tetrasilicate and absolute ethanol (volume ratio 20:80) and aged at 50° C. for 50 hours.

[0030] 2. Preparation of silica airgel

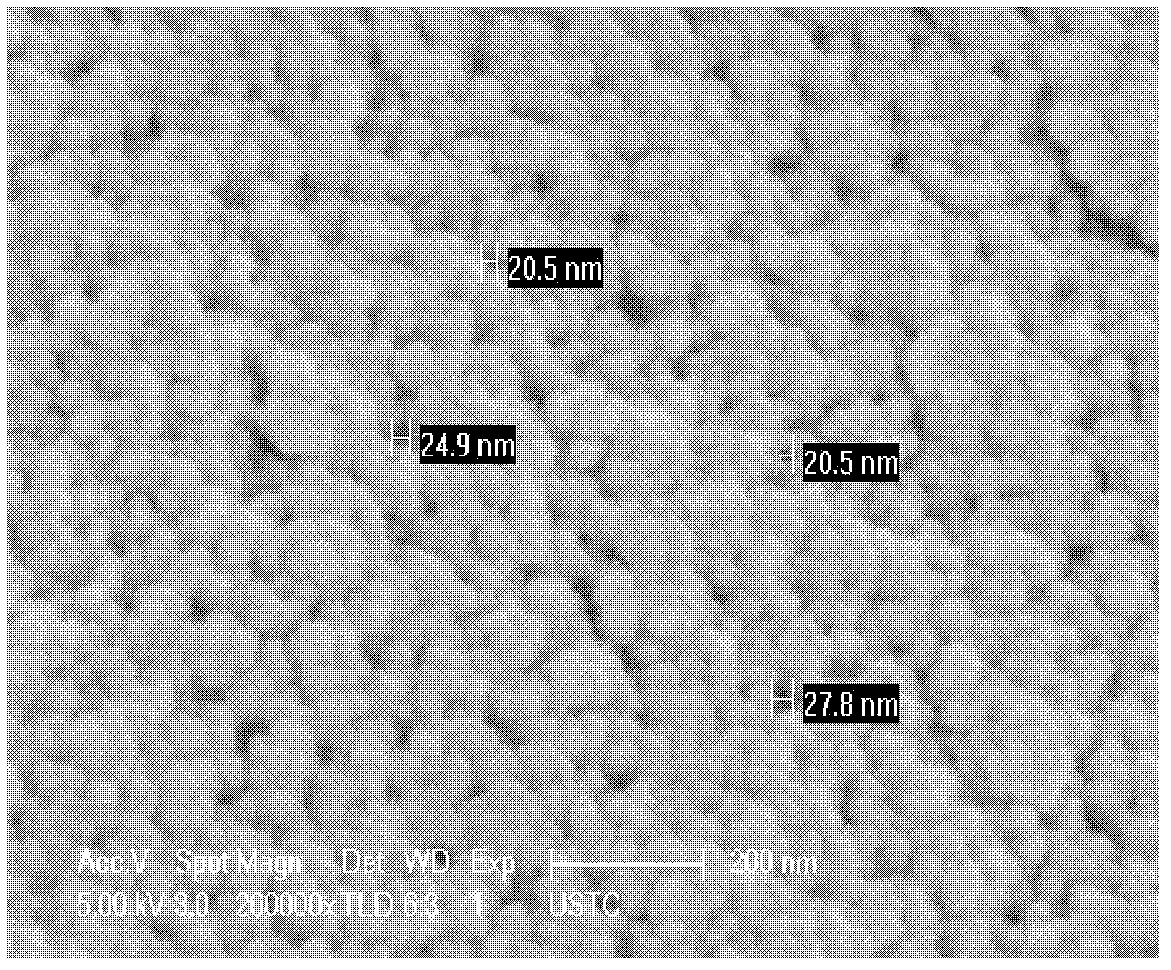

[0031] to the aged SiO 2 Add n-hexane to the alcohol gel for solvent exchange, once a day, exchange three times, and then place it in 10vt% trimethylchlorosilane n-hexane solution for immersion for 48 hours. °C, 100 °C and 120 °C for 4 hours to obtain nano-sized SiO 2 Airgel powder.

[0...

Embodiment 2

[0039] The preparation method of this embodiment is the same as that of Example 1, except that the addition amount of methyltriethoxysilane in step 1 is 4.46g, and the addition amount of deionized water is 7.20g; the n-hexane of trimethylchlorosilane in step 2 The volume concentration of the solution is 5vt%; the mass of -NCO-terminated polyurethane in step 3 is 30% of the mass of the dehydrated phenolic resin, and the reaction time is 13 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com