Composite material with formaldehyde purification function and production method thereof

A composite material and functional technology, applied in the fields of chemical industry, building materials, and light industry, can solve the problems of long absorption and conversion cycle, limited purification capacity, poor purification effect of formaldehyde, etc., and achieve remarkable purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

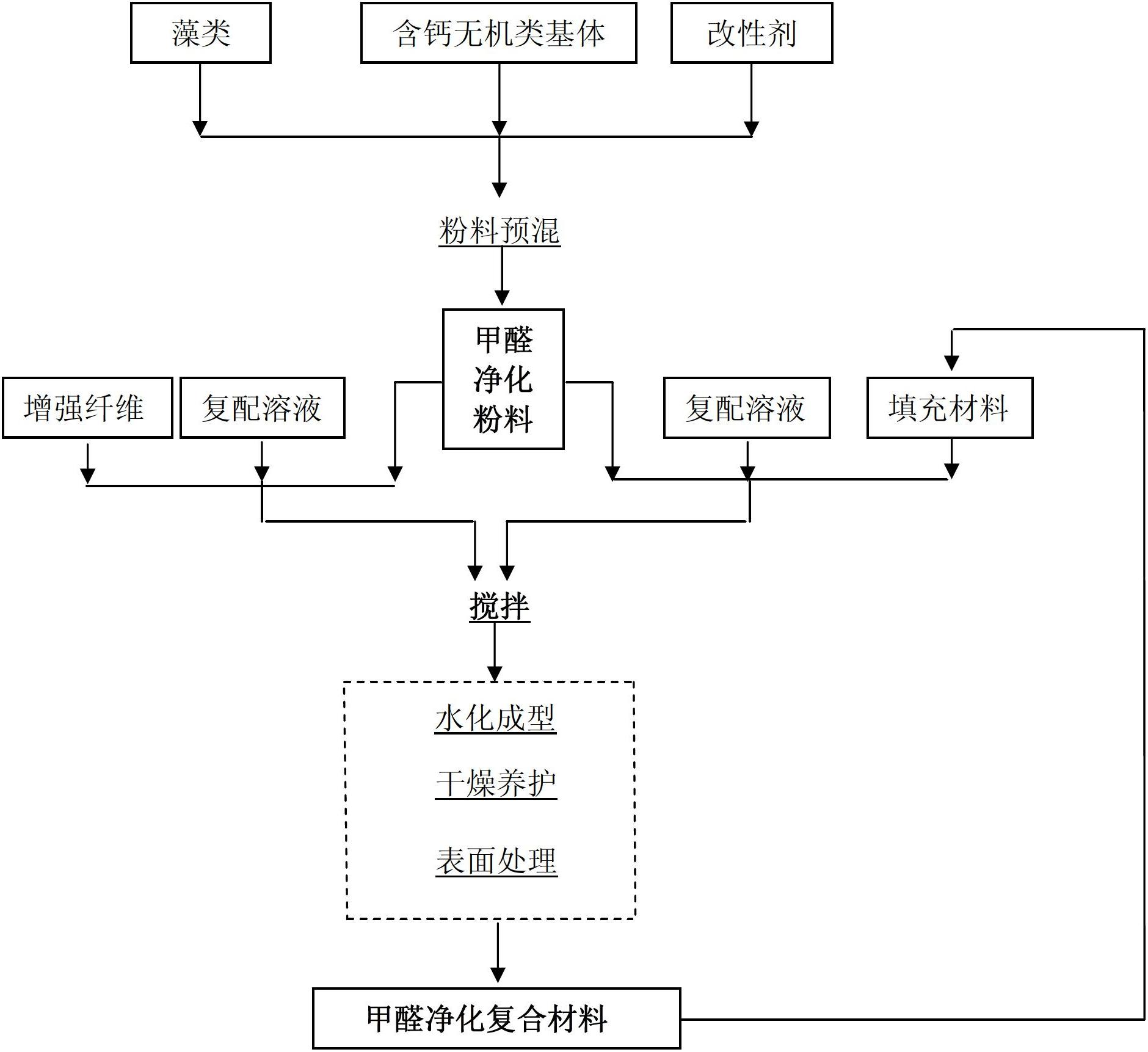

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: A kind of powder with formaldehyde purification function

[0047] 1. Formula composition (substances are measured in parts by weight):

[0048] (1) 48.8 parts of natural β-calcium sulfate hemihydrate;

[0049] (2) Diatomite: 10 parts of ground diatomite powder with a particle size of 400-800 mesh;

[0050] (3) Modifier: 6 parts of compound powder uniformly mixed with 54% calcium oxide, 36% silicon oxide and 10% polyvinyl alcohol;

[0051] 2. Production and preparation process:

[0052] (1) Pretreatment of raw materials: β-calcium sulfate hemihydrate, diatomaceous earth, and modifiers are accurately measured according to 41 parts, 12 parts, 4 parts, and 2 parts respectively;

[0053] (2) After pre-mixing, it is prepared by aging in an aging warehouse for 3-15 days.

Embodiment 2

[0054] Example 2: A wood-like board with formaldehyde purification function

[0055] 1. Formula composition (substances are measured in parts by weight):

[0056] (1) 54.8 parts of natural calcium phosphate;

[0057] (2) Diatomite: 16 parts of ground diatomite powder with a particle size of 400-800 mesh;

[0058] (3) Modifier: 6 parts of compound powder uniformly mixed with 54% calcium oxide, 36% silicon oxide and 10% polyvinyl alcohol;

[0059] (4) Reinforced fiber chopped shreds: 1.20 parts of plant fiber with a length of 15-18 mm;

[0060] (5) Composite solution: clear water, crystal modifier, waterproofing agent, and defoamer are mixed and stirred according to their mass ratio of 100:1.8:0.4:0.5 to form 22 parts of a uniform compound solution. The crystal-transforming agent is sodium citrate; the waterproofing agent is sodium methyl siliconate; and the defoamer is tributyl phosphate.

[0061] 2. Production and preparation process:

[0062] (1) Pretreatment of raw mate...

Embodiment 3

[0067] Example 3: A granular composite material with formaldehyde purification function

[0068] 1. Formula composition (substances are measured in parts by weight):

[0069] (1) 54.8 parts of natural calcium aluminate;

[0070] (2) Seaweed earth: 10 parts of seaweed earth powder with a particle size of 400-800 mesh and ground;

[0071] (3) Modifier: 3 parts of compound powder uniformly mixed with 54% calcium oxide, 36% silicon oxide and 10% polyvinyl alcohol;

[0072] (4) Reinforced fiber chopped shreds: 0.8 parts of plant fiber with a length of 15-18 mm.

[0073] 2. Production and preparation process:

[0074] (1) Pretreatment of raw materials: Accurately measure calcium aluminate, seaweed, and modifiers according to the above weight parts, pre-mix them, and age them in an aging warehouse for 3 to 15 days to prepare mixed powder;

[0075] (2) Stirring of the mixture: mix the accurately measured mixed powder and plant fiber according to the above weight parts;

[0076] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com