Fast-baking explosion proof type refractory castable for blast furnace iron runner

A refractory castable and explosion-proof technology, applied in the field of refractory materials, can solve the problems of density, strength reduction, low iron flux at one time, poor erosion resistance, etc., and achieve high density, good corrosion resistance, and explosion-proof temperature. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Quick-drying explosion-proof refractory castable for blast furnace iron trench, its composition ratio is (percentage by weight): dense corundum particles 20%, white corundum particles 35.5%, white corundum fine powder 15%, silicon carbide 20%, silicon oxide powder 2 %, alumina micropowder 5%, aluminate cement 2.5%, plus explosion-proof fiber 0.2%, metal aluminum powder 1%, azodicarbonamide 0.2%, silica sol 3%, flake graphite 4%, polyethylene glycol polycondensation 0.15% superplasticizer, 3% bentonite.

Embodiment 2

[0032] Quick-drying explosion-proof refractory castable for blast furnace iron trench, its composition ratio is (percentage by weight): 20% white corundum particles, 40.5% super-grade bauxite particles, 15% white corundum fine powder, 15% silicon carbide, silicon oxide micropowder 3%, alumina micropowder 4%, aluminate cement 2.5%, plus explosion-proof fiber 0.2%, metal aluminum powder 1%, azodicarbonamide 0.3%, silica sol 3%, flake graphite 3%, sodium polyacrylate Aqua 0.17%, bentonite 3%.

Embodiment 3

[0034] The quick-drying explosion-proof refractory castable for blast furnace iron ditch, its composition ratio is (percentage by weight): super-grade bauxite particles 58%, super-grade bauxite fine powder 15%, silicon carbide 18%, silicon oxide micro-powder 2%, alumina Micropowder 4%, aluminate cement 3%, plus explosion-proof fiber 0.2%, metal aluminum powder 0.8%, azodicarbonamide 0.2%, silica sol 1%, flake graphite 2%, polyacrylate sodium water reducing agent 0.15%, Ball Clay 2%.

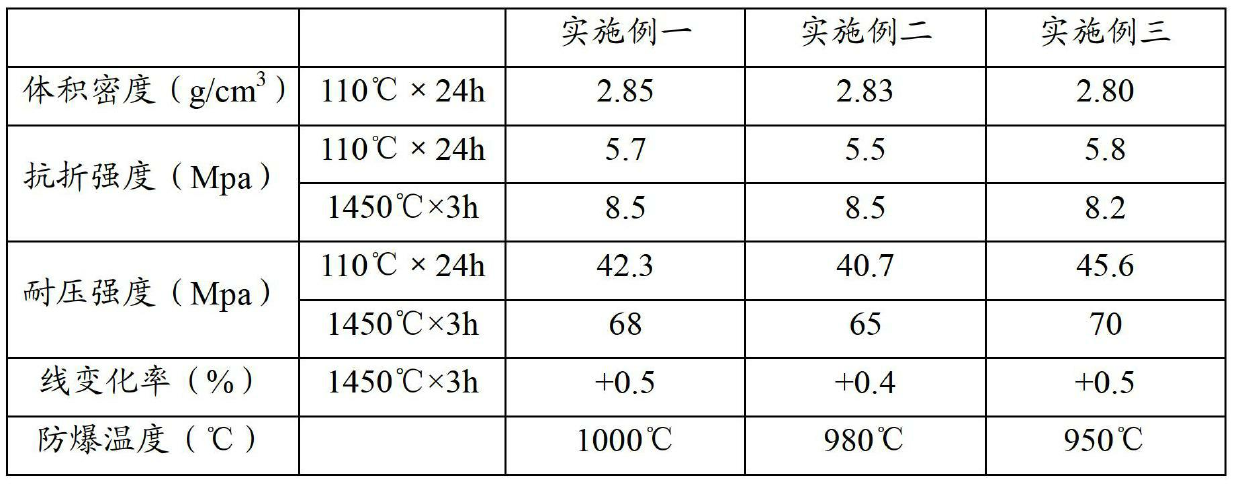

[0035] Table 1 lists the performance indicators of the quick-drying explosion-proof refractory castables for blast furnace iron trenches in Examples 1 to 3. From the performance index analysis shown in Table 1, it can be seen that the explosion-proof temperature of the quick-dried explosion-proof refractory castable for blast furnace iron trench of the present invention is 950-1000 ° C, and the bulk density at 110 ° C × 24h is 2.80-2.85 g / cm 3 , 110℃×24h flexural strength is 5.5-5.8Mpa, 1450℃×3h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com