Dry acetylene generation and separation device

A separation device, acetylene generator technology, applied in the purification/separation of hydrocarbons, hydrocarbons, hydrocarbons, etc., can solve the problems of low acetylene yield, inability to stir materials by a stirring shaft, waste of raw materials, etc., to achieve reaction conversion The effect of high efficiency, simple and reasonable structure, and not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

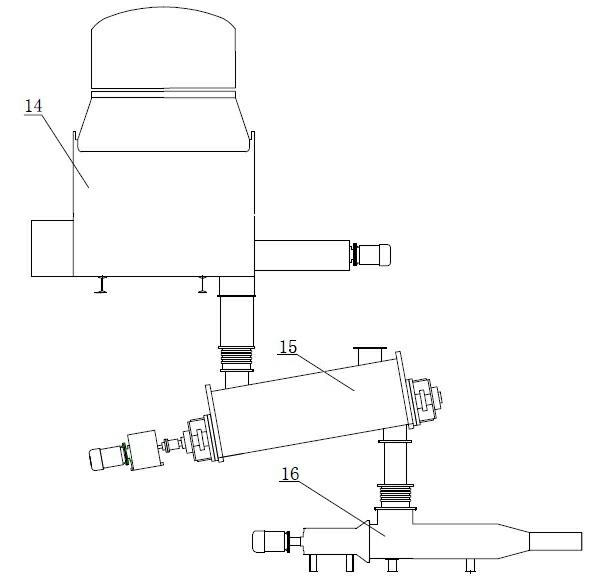

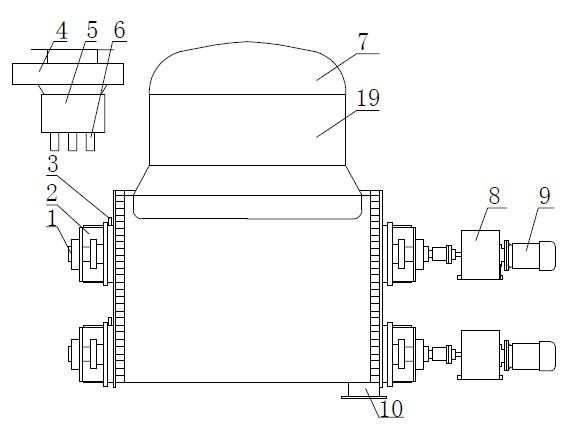

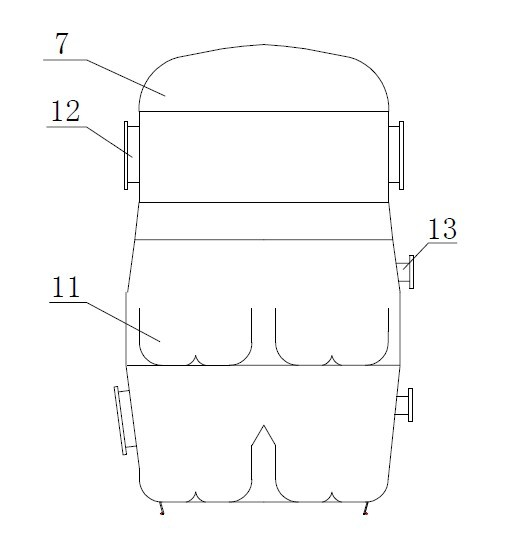

[0027] Such as Figure 1 to Figure 3 As shown, the dry type acetylene generation and separation device of the present invention includes a feed device, an acetylene generator 14, an acetylene recovery device 15 and an extrusion slagging device 16, and the feed device includes a feed valve 4, a homogenizer 5 and four The feeding branch pipe 6 and the feeding valve 4 are arranged above the homogenizer 5, and four feeding branch pipes 6 are arranged below the homogenizer 5. The acetylene generator 14 includes an acetylene generating box, a stirring shaft 1 arranged in the acetylene generating box, Reducer 8 and motor 9, the top of the acetylene gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com