Creatine phosphate sodium preparation method

A technology of sodium creatine phosphate and chlorophosphoric acid, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve problems such as high production costs, cumbersome post-processing, and harmfulness of barium. Achieve the effects of low production cost, simple post-processing, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

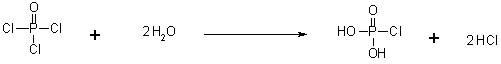

[0047] a) In the reaction flask equipped with sodium hydroxide absorption device, add phosphorus oxychloride POCl 3 (153.33g, 1.0mol), cool down in an ice-water bath to 0°C~5°C, slowly add deoxygenated water (36g, 2.0mol) dropwise, after the addition, control the temperature of the reaction solution at 5°C~10°C and stir for 2 hours. Airtight storage for later use;

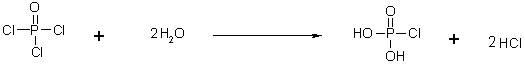

[0048] b) In the reaction flask equipped with sodium hydroxide absorption device, add S-methylisothiourea (60.0g, 0.67mol), N,N-dimethylformamide DMF 600mL, stir well and add the above prepared Chlorophosphoric acid 1mol, control the temperature of the reaction solution at 35°C~40°C and stir for 5 hours, evaporate N,N-dimethylformamide under reduced pressure to obtain phosphorylated S-methylisothiourea (114g, 0.67mol). The intermediate of this step reaction does not need to be purified in full amount to continue to do it;

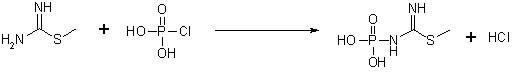

[0049] c) In the reaction flask equipped with a sodium hydroxide absorption device, add th...

Embodiment 2

[0052] a) In the reaction flask equipped with sodium hydroxide absorption device, add phosphorus oxychloride POCl 3 (153.33g, 1.0mol), cooled in an ice-water bath to 0°C~5°C, slowly added deoxygenated water (36g, 2.0mol) dropwise, after the addition, controlled the temperature of the reaction solution at 0°C~5°C and stirred for 3 hours. Airtight storage for later use;

[0053] b) Add S-methylisothiourea (45.0g, 0.50mol) and 450mL dimethyl sulfoxide into the reaction flask equipped with a sodium hydroxide absorption device, stir well and add 1mol of chlorophosphoric acid prepared above to control the reaction The solution was stirred at a temperature of 20°C to 30°C for 6 hours, and the dimethyl sulfoxide was distilled off under reduced pressure to obtain phosphorylated S-methylisothiourea (85.0 g, 0.5 mol). The intermediate of this step reaction does not need to be purified in full amount to continue to do it;

[0054] c) Add the phosphorylated S-methylisothiourea (85.0g, 0....

Embodiment 3

[0057] a) In the reaction flask equipped with sodium hydroxide absorption device, add phosphorus oxychloride POCl 3 (153.33g, 1.0 mol), cool down to 0°C~5°C in an ice-water bath, slowly add deoxygenated water (36 g, 2.0 mol) dropwise, after the addition, control the temperature of the reaction solution at 2°C~7°C and stir for 2.5 hours . Airtight storage for later use;

[0058] b) Add S-methylisothiourea (60.0g, 0.67mol) and 600mL of acetone to the reaction flask equipped with a sodium hydroxide absorption device, stir well and add 0.67mol of chlorophosphoric acid prepared above to control the temperature of the reaction solution Stir at 40°C~50°C for 2 hours, distill off the acetone under reduced pressure to obtain phosphorylated S-methylisothiourea (114g, 0.67mol). The intermediate of this step reaction does not need to be purified in full amount to continue to do it;

[0059] c) In the reaction flask equipped with a sodium hydroxide absorption device, add the phosphoryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com