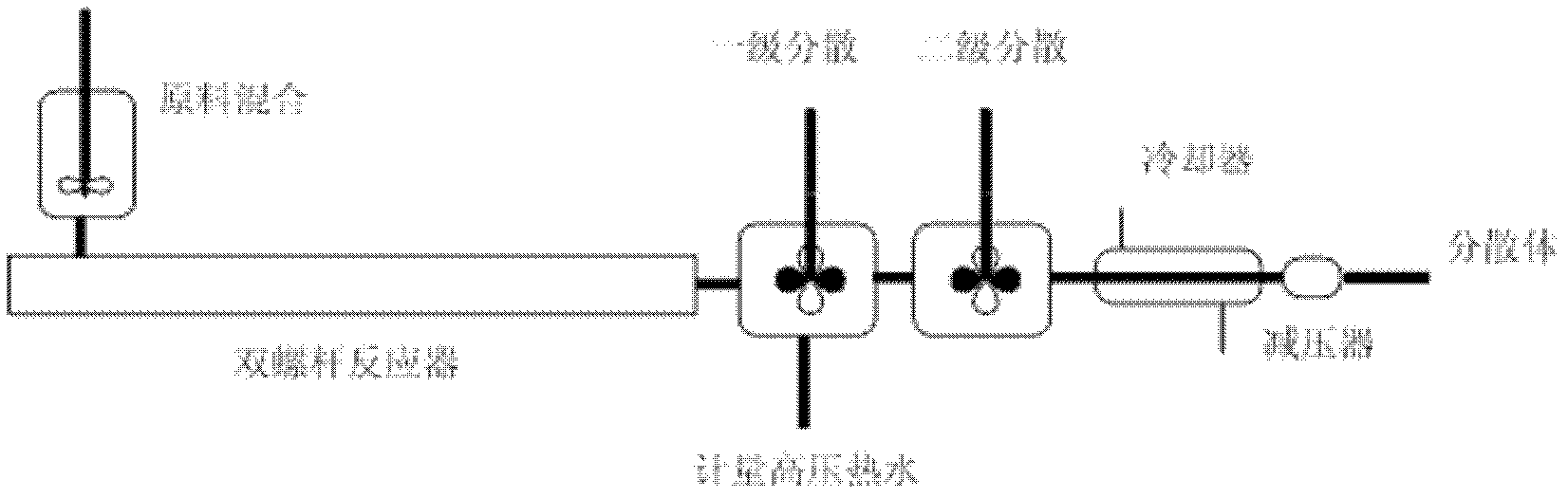

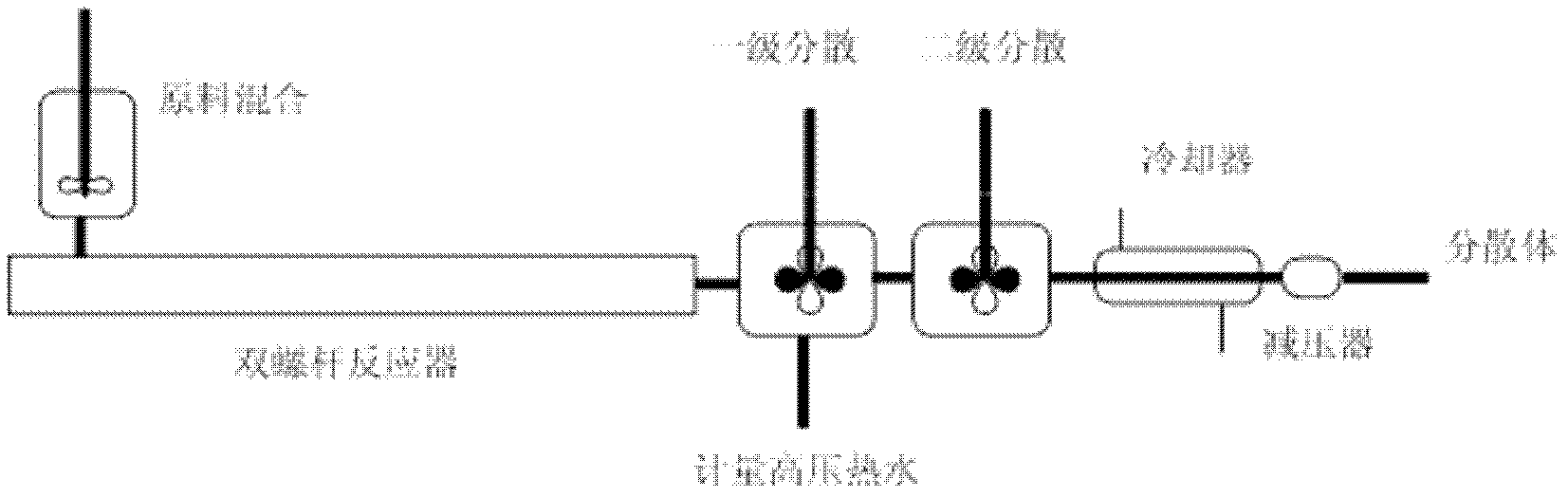

Double-screw reactor design based continuous production process of aqueous polyurethane dispersion

A twin-screw reactor, water-based polyurethane technology, which is applied in the field of new chemical materials, can solve the problems of long production cycle, low equipment use efficiency, and cannot be reused, and achieves the effect of short production cycle and automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] 500 parts of polytetrahydrofuran diol (Mn=2000), 60 parts of 2-methyl 1,3 propanediol, 248 parts of isophorone diisocyanate (IPDI), 55 parts of dimethylol propionic acid (DMPA), mixed and preheated to 70 DEG C are injected twin-screw reactor, twin-screw reactor temperature is controlled at 220 DEG C, and extrusion time is controlled at 10 minutes. After the prepolymer is extruded from the extruder, it is directly extruded into the primary disperser, and the metered triethylamine aqueous solution is injected into the primary disperser simultaneously, and the temperature of the injected triethylamine aqueous solution is controlled at 90°C. The primary disperser adopts mechanical dispersion, the dispersion temperature is controlled at 130°C, and the pressure is controlled at 0.3MPa. The primary dispersion liquid enters the secondary disperser, and the secondary disperser adopts ultrasonic dispersion, and the temperature and pressure are the same as the primary disperser. T...

example 2

[0037]Polytetrahydrofuran diol (Mn=2000) 500 parts, 2-methyl 1,3 propanediol 60 parts, isophorone diisocyanate (IPDI) 248 parts, dimethylol propionic acid (DMPA) 55 parts, N-formaldehyde 50 minutes of pyrrolidone, 40 minutes of triethylamine were mixed and injected into the twin-screw reactor, and the temperature of the twin-screw reactor was controlled at 140° C., and the extrusion time was controlled at 10 minutes. After the prepolymer is extruded from the extruder, it is directly extruded into the primary disperser, and the metered temperature of 90°C distilled water is injected into the primary disperser at the same time. The primary disperser adopts mechanical dispersion, the dispersion temperature is controlled at 100°C, and the pressure is controlled at 0.1MPa. The primary dispersion liquid enters the secondary disperser, and the secondary disperser adopts ultrasonic dispersion, and the temperature and pressure are the same as the primary disperser. The dispersion throu...

example 3

[0039] Polytetrahydrofuran diol (Mn=2000) 500 parts, 2-methyl 1,3 propanediol 50 parts, toluene diisocyanate (TDI) 170 parts, N-methyldiethanolamine 30 parts, N-methylpyrrolidone 50 parts, bis The temperature of the screw reactor was controlled at 120° C., and the extrusion time was controlled at 15 minutes. After the prepolymer is extruded from the extruder, it is directly extruded into the first-level disperser, and the metered temperature is injected into the first-level disperser at the same time as an aqueous formic acid solution with a temperature of 90°C. The primary disperser adopts mechanical dispersion, the dispersion temperature is controlled at 100°C, and the pressure is controlled at 0.1MPa. The primary dispersion liquid enters the secondary disperser, and the secondary disperser adopts ultrasonic dispersion, and the temperature and pressure are the same as the primary disperser. The dispersion through the secondary disperser enters the pipeline cooler, is cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com