Methane production device without energy consumption suitable for cold region in winter

A technology for production equipment in cold regions, applied in the field of anaerobic reactors with new structures and its auxiliary facilities, can solve the problems of reduced gas production, high energy consumption for warming, and backward technical methods, so as to prevent sudden temperature drops and improve storage Good effect and heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

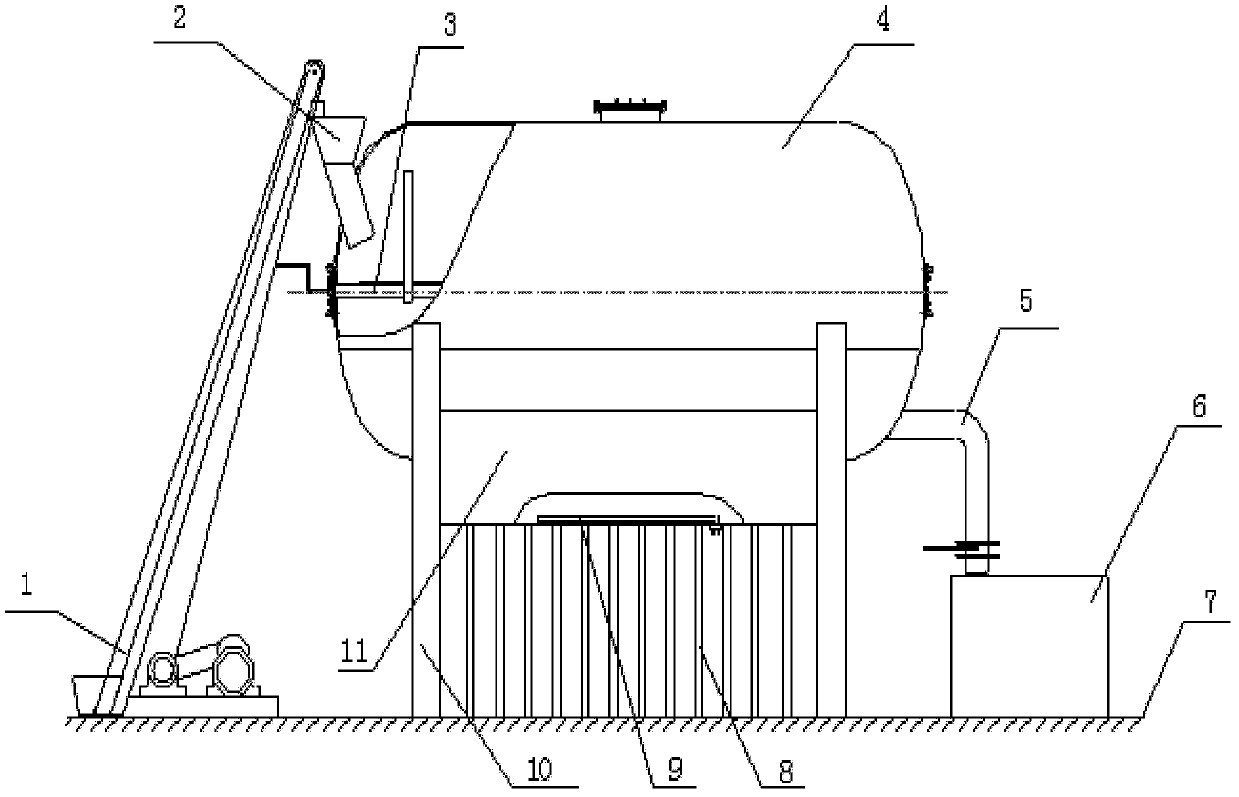

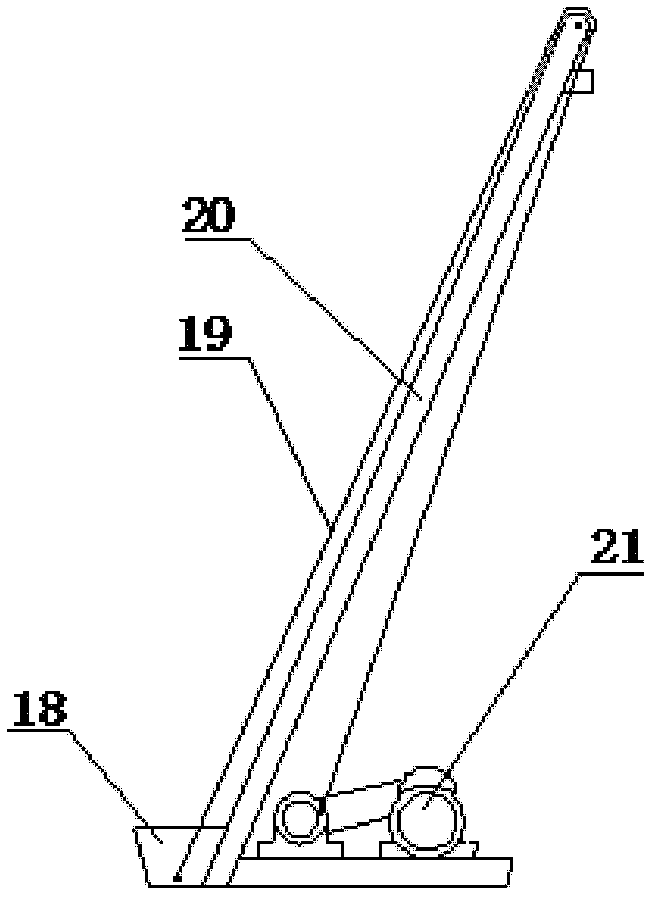

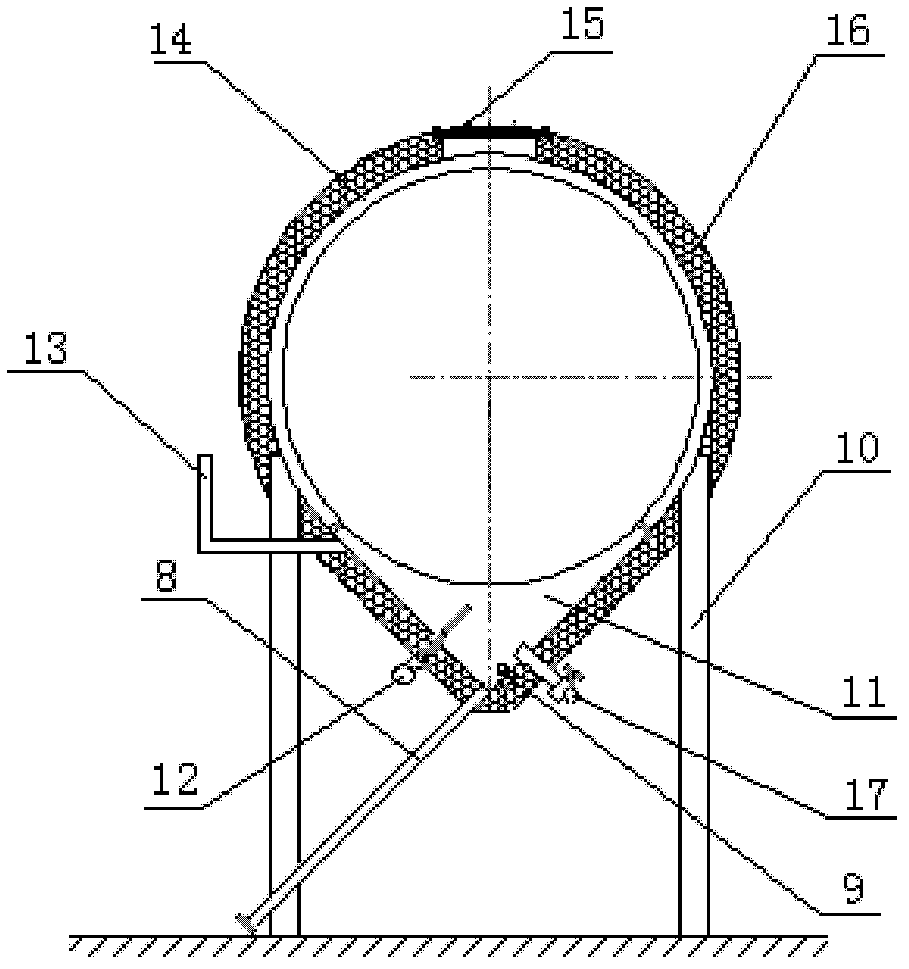

[0023] As shown in the figure, the non-energy-consuming biogas production device in winter in this cold region is mainly composed of a feed device 1, an anaerobic reactor 4, a heat storage tank 11, a solar vacuum heat collection tube 8, an agitator 3, an external tank insulation 16, a discharge Material system composition. Put down the shading plate of the solar vacuum heat collecting tube 8 before operation to reduce its temperature, and when the temperature of the solar vacuum heat collecting tube 8 drops below 40°C, fill the water storage tank 11 with water to prevent the solar vacuum heat collecting tube 8 from When the temperature is too high, the cold water bursts, and the liquid level gauge 13 is observed until the water storage tank 11 is filled with water. Mix the feces with the cut straw, mix according to the C / N ratio of 25:1, add a small amount of water, cover with plastic film, stack retting for 3 to 5 days, and then start feeding. When feeding through the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com