Preparation method for methotrexate/layered double hydroxide nanocomposite

A nano-composite material, layered bimetal technology, applied in the direction of drug combination, medical preparations with inactive ingredients, medical preparations containing active ingredients, etc. Large and other problems, to achieve the effect of low equipment cost, energy saving and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) At room temperature, Mg(NO 3 ) 2 ?6H 2 O and Al(NO 3 ) 3 ?9H 2 O carry out pre-grinding 2min;

[0034] 2) Prepare a NaOH solution with a concentration of 10.5mol / L;

[0035] 3) Weigh 0.7692g Mg(NO 3 ) 2 ?6H 2 O and 0.5627g Al(NO 3 ) 3 ?9H 2 O placed in an agate mortar in which Mg 2+ / Al 3+ =2:1; add 0.3408g MTX, then drop 1.15ml of the NaOH solution prepared in step 2), mix well, and grind at a constant speed for 60min. Centrifuged and washed 4 times with distilled water to obtain the MTX / LDH precursor;

[0036] 4) Add water to the precursor prepared in step 3) and sonicate to prepare a 2mol / L precursor solution, and then put it into a polytetrafluoroethylene-lined reactor for peptization. The peptization temperature is 80°C. The melting time was 24 hours, and the product was dried to obtain the MTX / LDH nanocomposite material.

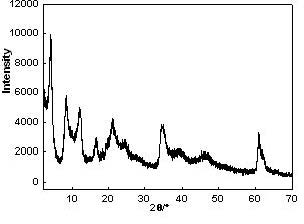

[0037] figure 1 The XRD pattern of the MTX / LDH nanocomposite material that is the present embodiment made, figure 1 showed...

Embodiment 2

[0041] 1) At room temperature, Zn(NO 3 ) 2 ?6H 2 O and Al(NO 3 ) 3 ?9H 2 O carries out pre-grinding 5min;

[0042] 2) Prepare NH with a concentration of 8mol / L 3 ?H 2 O solution;

[0043] 3) Weigh 0.9520g Zn(NO 3 ) 2 ?6H 2 O and 0.5627g Al(NO 3 ) 3 ?9H 2 O is placed in a grinding tool, where Zn 2+ / Al 3+ =2:0.8; add 0.3636 gMTX, then drop 2.8ml of NH prepared in step 2) 3 ?H 2 O solution, mix evenly, and grind at a constant speed for 40 minutes. Centrifuged and washed 3 times with distilled water to obtain the MTX / LDH precursor;

[0044] 4) Add water to the precursor prepared in step 3) and sonicate to prepare a 0.5mol / L precursor solution, put it in the reaction kettle for peptization, the peptization temperature is 100°C, and the peptization time is 48h, and the product is dried. Prepared MTX / LDH nanocomposites.

[0045] The resulting XRD pattern shows that: with the parent LDH-NO 3 Compared to the composite d 003 The characteristic diffraction peak shi...

Embodiment 3

[0047] 1) At room temperature, Mg(NO 3 ) 2 ?6H 2 O and Fe(NO 3 ) 3 ?9H 2 O carries out pre-grinding 3min;

[0048] 2) Prepare a NaOH solution with a concentration of 12mol / L;

[0049] 3) Weigh 0.6410 g Mg(NO 3 ) 2 ?6H 2 O and 0.6060g Fe(NO 3 ) 3 ?9H 2 O placed in the grinding utensils, wherein, Mg 2+ / Fe 3+ =2:1.2; Add 0.2840 gMTX, then drop 1.57ml of the NaOH solution prepared in step 2), mix well, and grind at a constant speed for 160min. Centrifuged and washed 4 times with distilled water to obtain the MTX / LDH precursor;

[0050] 4) Add water to the precursor prepared in step 3) and sonicate it to prepare a 3mol / L precursor solution, and put it into a polytetrafluoroethylene-lined reactor for peptization. The peptization temperature is 120°C. The time was 12 h, and the product was dried to obtain the MTX / LDH nanocomposite material.

[0051] The resulting XRD pattern shows that: with the parent LDH-NO 3 Compared to the composite d 003 The characteristic dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

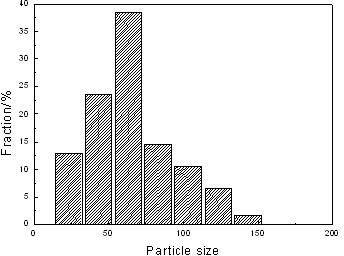

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com