Method for recovering 4-methyl-2-pentanone from tiamulin wastewater by acidification and wastewater treatment method

A technology for tiamulin and wastewater, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The win-win effect of COD, low cost, environmental governance and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Research on the steps of salting out:

[0023] Take 1L of tiamulin waste water and carry out salting-out treatment. The salts used are: sodium chloride, sodium sulfate, and calcium chloride, and the addition ratio is 0.5% of the mass of the tiamulin waste water. filter, after suction filtration, dry the precipitated substance, then weigh, and the weights are respectively:

[0024]

[0025] From the above experiments, it can be seen that the effect of adding sodium chloride for salting out is the best, the most solid matter is precipitated, and the effect of reducing COD and solvent separation of sewage is the best.

[0026] 2. Research on acidification steps:

[0027] Take 1L of tiamulin wastewater, and carry out acid adjustment treatment. The acids used are: concentrated sulfuric acid (98wt%), concentrated hydrochloric acid (36wt%), concentrated phosphoric acid (85wt%), and the pH of the wastewater is adjusted to 5.0. The amount is shown in the following table....

Embodiment 2

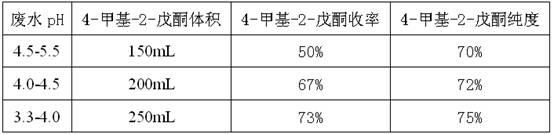

[0030] Take 1L of tiamulin wastewater, first add 0.5% sodium chloride of wastewater quality for salting out operation, and then adjust the pH value with concentrated sulfuric acid, so that the pH value of tiamulin synthetic wastewater is in the range of 4.5-5.5, 4.0-4.5 Within the range of 3.3-4.0, stand and separate for 6h, collect the ketone phase after the separation, the obtained 4-methyl-2-pentanone is as follows:

[0031]

[0032] It can be seen from the above results that the recovery of 4-methyl-2-pentanone is the best when the pH range of the wastewater is 3.3-4.0.

Embodiment 3

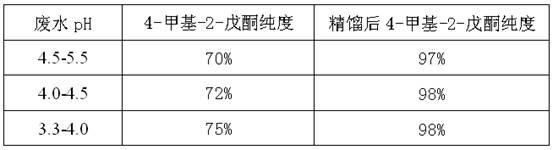

[0034] Further, the 4-methyl-2-pentanone isolated in Example 2 can also be added to a rectification tower for rectification to improve the purity, and the product purity after rectification is as follows:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com