Method and system for treatment and recycling of feces and waste from livestock and poultry culture

A technology for livestock and poultry breeding and manure, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problems of long treatment cycle, long hydraulic retention time, low biodegradability, etc., and achieve investment and low operating costs, realize zero discharge of biogas residues, and improve the effect of sludge utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

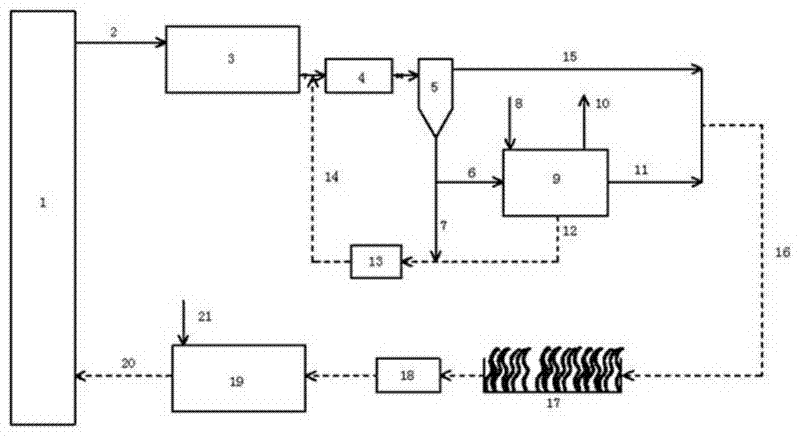

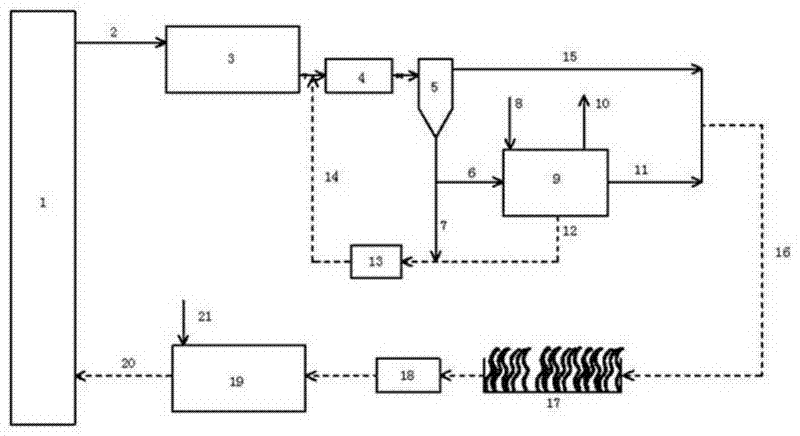

[0035] The present invention will be further described in conjunction with the accompanying drawings.

[0036] Taking the manure treatment of pig farms as an example, the dry manure and sewage are separated by the dry manure cleaning process.

[0037] The waste water from the pig farm 1 is stored in the sewage regulating pool 3 through the pipeline 2. The setting of this pool solves the problem of inconstant and discontinuous incoming sewage for flushing the pig house, and makes it easy to adjust the flow rate and flow rate of the water flowing into the adsorption pool. The water in the sewage adjustment tank is lifted into the adsorption tank 4 by the pump, and fully stirred and mixed with the activated sludge in the adsorption tank 4. Under the condition of aeration, after fully contacting for about 30 minutes, part of the suspended matter, colloid and soluble state Organic pollutants are adsorbed by activated sludge, and organic substances in organic sewage are enrich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com