Terminal modified organic silicone coating flatting agent and preparation method thereof

A technology of silicone coating and leveling agent, applied in the direction of coating, etc., can solve the problems of limited slip and scratch resistance, and achieve the effects of excellent smoothness, reduced surface tension and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

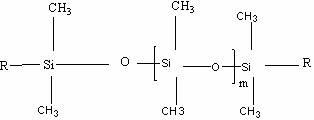

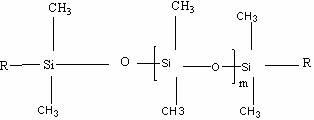

Image

Examples

Embodiment 1

[0031] Preparation of terminal H-containing silicone oil

[0032] In a 2000ml three-necked flask equipped with an electric stirrer and a thermometer, add 1148 grams of DMC (dimethylcyclosiloxane mixed ring), 52 grams H MM H (Tetramethylhydrogendisiloxane), 40 grams of concentrated sulfuric acid, heated to 50°C, kept the temperature for 10 hours, then added 60 grams of sodium bicarbonate to neutralize, filtered to remove salt, and finally distilled at 120°C and 1.3KPa , to remove low boilers, to obtain a colorless and transparent dimethyl silicone oil containing H at the end, the viscosity measured by a capillary viscometer is 50cs (25°C), and the H content is 0.06%.

Embodiment 2

[0034] Synthesis of H-terminal silicone oil

[0035]Using macroporous cationic resin instead of concentrated sulfuric acid as catalyst, the reaction device, reactant, charging amount and operation method are the same as in Example 1. Heat up to 50°C, keep it warm for 10 hours, remove the catalyst by filtration, distill at 120°C and 1.3KPa to remove low boilers, and obtain a colorless and transparent dimethyl silicone oil containing H at the end, and measure its viscosity with a capillary viscometer It is 50cs (25°C), and the H content is 0.06%.

Embodiment 3

[0037] In a 2000ml four-necked glass reaction flask equipped with an electric stirrer, a thermometer, a reflux condenser, and a nitrogen gas guide tube, add 420 grams of the end-containing H silicone oil prepared in Example 1, and the structural formula is CH 2 =CHCH 2 -O-(C 2 h 4 o) 14 (C 3 h 6 O) 10 -COCH 3 390 grams of allyl alcohol polyether, 400 grams of toluene, pass through dry nitrogen, start the electric stirrer, and heat, when the temperature reaches 60 ° C, add platinum-divinyltetramethyldisiloxane chelate 0.5 g (the amount of platinum added is 10×10 of the total mass of reactants -6 ), when the system temperature reaches 80°C, suspend heating, and the reactant turns from turbid to transparent, and keep warm at 80-110°C for 6 hours. The completion of the Si-H reaction was detected with potassium hydroxide alcohol solution, and the solvent was removed by vacuuming to obtain terminal polyether-modified polydimethylsiloxane, whose viscosity was measured by a ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com