Catalyst for oxidative dehydrogenation of raw materials containing CO (carbon monoxide) gas

A technology for oxidative dehydrogenation and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, carbon monoxide, etc., can solve the problems of high CO loss rate and low hydrogen removal rate, and achieve The effect of good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Configure 100 grams of aqueous solution of praseodymium nitrate containing 3 grams of praseodymium, then pour it into a beaker that is equipped with 100 grams of aluminum oxide and silicon oxide in a weight ratio of 5: 1, dry it at 120 ° C after impregnation, and Roasting at 480 DEG C for 2 hours, then putting the calcined carrier into 100 g of palladium nitrate aqueous solution containing 0.3 g of palladium, impregnating and adsorbing for 6 hours, and then roasting at 480 DEG C to obtain CO-containing gas raw material oxidative dehydrogenation catalyst A, wherein , by weight percentage, the content of palladium oxide is 0.4%, and the content of praseodymium oxide is 4%.

[0024] Weigh 50 grams of the prepared catalyst A, put it into a fixed-bed reactor, and use a CO-containing mixed gas with a hydrogen volume content of 1.2% as the raw material gas, at a reaction temperature of 200 ° C, and a gas volume space velocity of 3000 h -1 , the pressure is 0.2MPa, and the oxyg...

Embodiment 2~15

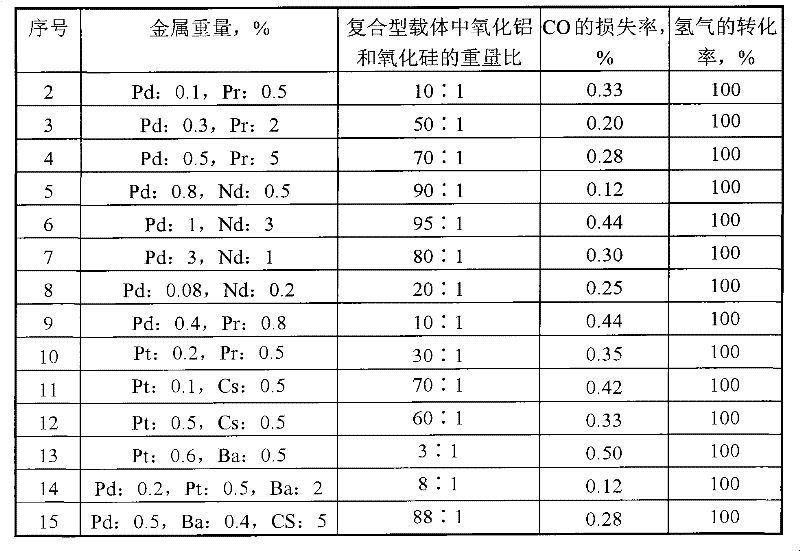

[0026] The preparation process and reaction conditions are the same as in Example 1, except that the content of active components, additives and the weight ratio of alumina to silica in the composite carrier are changed to obtain the catalyst and evaluate it in Table 1.

[0027] Table 1

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com