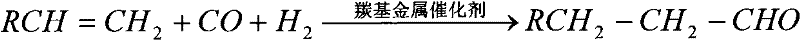

Method for preparing aldehyde through olefin hydrogen formylation

A technology of olefin hydroformylation and olefins, which is applied in the field of olefin hydroformylation to aldehydes, can solve the problems of low conversion rate of raw materials and low selectivity of target products, and achieve the effects of improving reaction efficiency, optimizing effective distribution, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

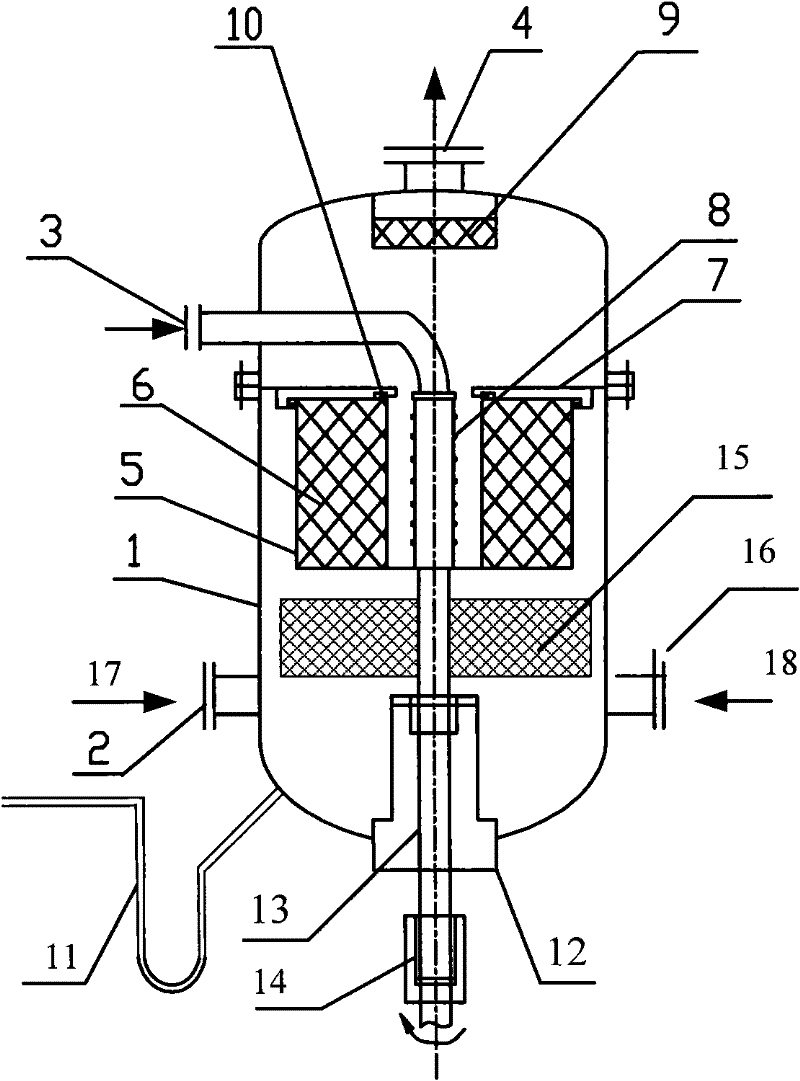

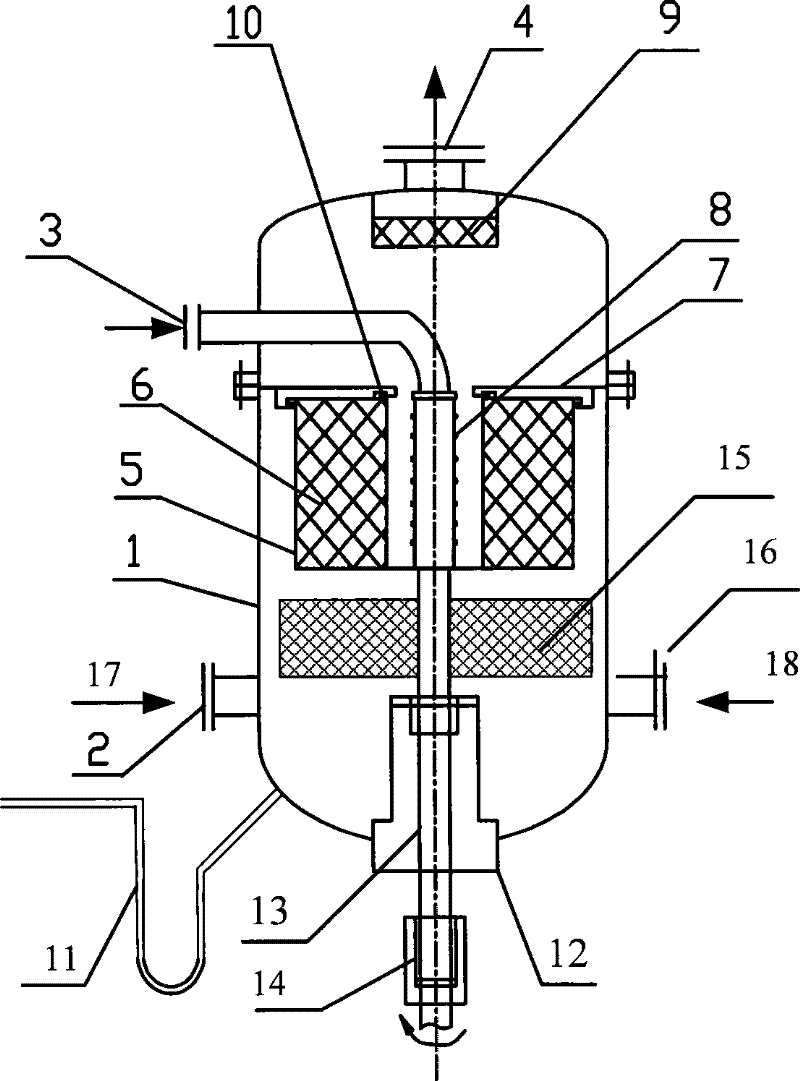

[0022] Attached figure 1 The shown device adopts the rhodium catalyst in Example 1 of document CN200910058201.6 as the catalyst, and the olefin is selected from ethylene, and the molar ratio of hydrogen: CO: ethylene: Rh is 1: 1: 0.8: 0.2; the total amount of gas is 100m 3 / h, under the condition that the molar ratio of the first mixed gas of hydrogen, CO and ethylene to the second mixed gas of hydrogen, CO and ethylene is 2:1, the two mixed gases are respectively fed from the first gas inlet 2 And the second gas inlet 16 enters the olefin hydroformylation reactor, and diffuses into the lower packing 15 under the action of pressure difference, and the rotating packing speed is adjusted to 2000rpm. The solution of rhodium-containing catalyst enters the liquid distributor 8 of the olefin hydroformylation reactor through the liquid inlet 3 and is sprayed to the inner side of the filler, and the gas and the liquid contact countercurrently in the upper packing layer 6 of the olef...

Embodiment 2

[0024] Attached figure 1 The shown device adopts the rhodium catalyst in Example 1 of the document CN200510085899.2 as the catalyst, and the olefin is selected from propylene, and in terms of total moles, the molar ratio of hydrogen: CO: propylene: Rh is 1: 1: 0.8: 0.2, the total amount of gas is 100m 3 / h, under the condition that the molar ratio of the first mixed gas of hydrogen, CO and propylene to the second mixed gas of hydrogen, CO and propylene is 30:1, the first mixed gas, the second mixed gas and the components containing liquid catalyst are respectively introduced in the high-efficiency reactor rotating packing layer 2 from the first gas inlet 1, the second gas inlet 10 and the liquid inlet 4, and the rotating packing layer rotating speed is adjusted to 500rpm, wherein the introduction of the first gas It is achieved by the pressure difference formed by the system. The liquid catalyst-containing component introduced through the liquid inlet line 5 merges with the...

Embodiment 3

[0026] Attached figure 1 The shown device adopts the rhodium catalyst in Example 2 of document CN 200910058201.6 as the catalyst, and the olefin is selected from butene, and the molar ratio of hydrogen: CO: butene: Rh is 1: 1: 0.7 in terms of total moles. : 0.2; under the condition that the molar ratio of the mixed gas of the first hydrogen, CO and butene to the mixed gas of the second hydrogen, CO and butene is 30:1, the first mixed gas, the second The mixed gas and the components containing liquid catalyst are respectively introduced into the high-efficiency reactor rotating packing layer 2 from the first gas inlet 1, the second gas inlet 10 and the liquid inlet 4, and the rotating packing layer speed is adjusted to 500rpm, wherein the first gas The introduction is achieved by the pressure difference formed by the system. The liquid catalyst-containing component introduced through the liquid inlet line 5 merges with the second gas introduced through the second gas inlet 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com