Method for recovering elementary-substance cobalt from lithium cobaltate in one step by utilizing microbial electrolysis cell

A technology of microbial electrolytic cell and lithium cobaltate, which is applied to the improvement of process efficiency, photographic process, instruments, etc., can solve the problems of high energy consumption and cost, cumbersome process, and many by-products, and achieve a clean and pollution-free process. The effect of environmental pollution treatment and resource utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

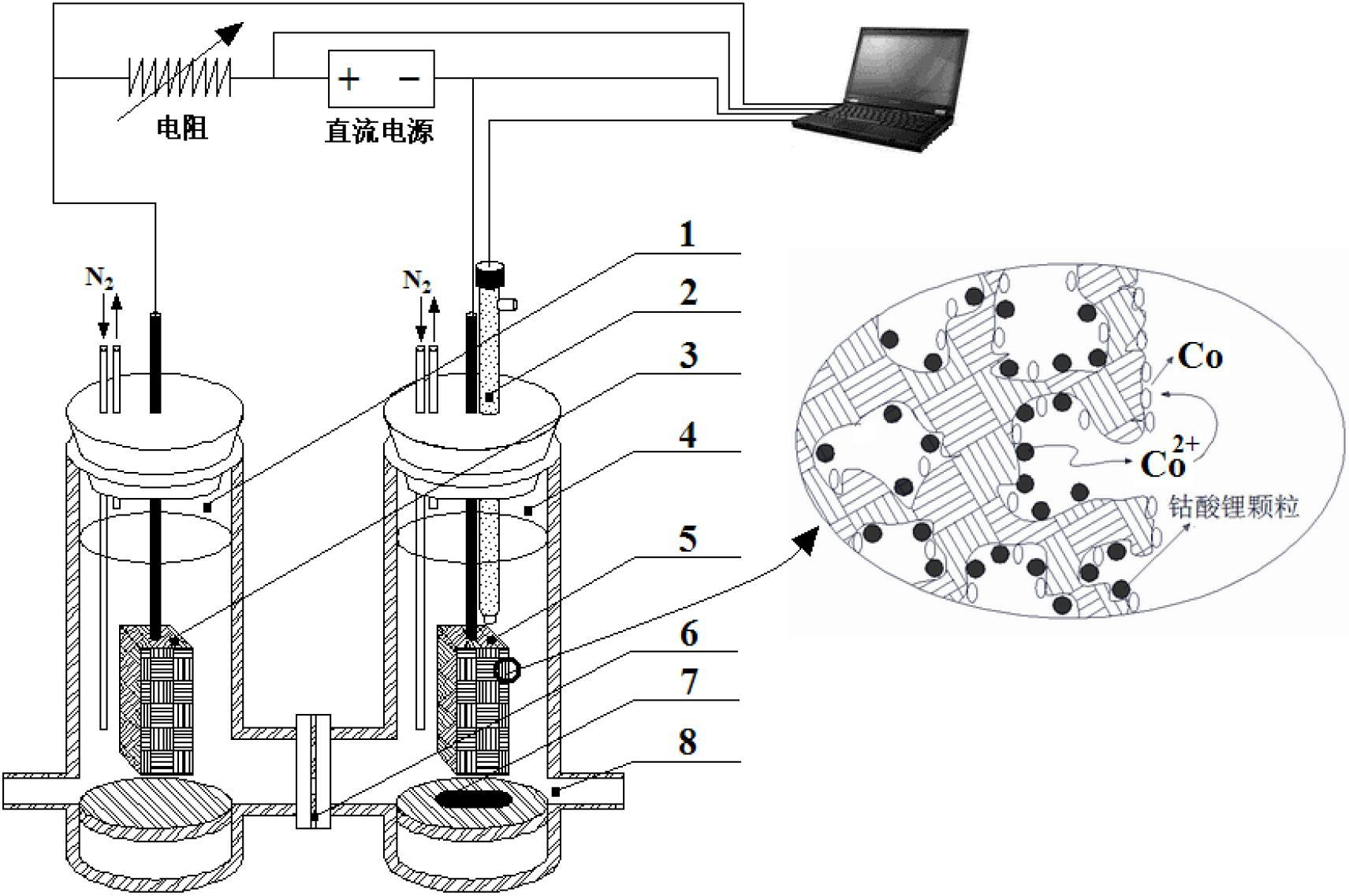

[0022] Step 1: Build a microbial electrolysis cell, such as figure 1 Shown: the anode chamber 1 and the cathode chamber 4 are made of plexiglass, with a total volume of 125 mL, respectively, and are separated by a proton permeable membrane (CMI-7000) 6.

[0023] Step 2: place anode electrode 2 and cathode electrode 5 in anode chamber 1 and cathode chamber 4 respectively, and the electrode materials of anode electrode 2 and cathode electrode 5 are graphite felt (Beijing Sanye Carbon Materials Company) (apparent size: 3 cm × 2 cm × 1 cm), connect 15 Ω external resistance and reference electrode 3 in the external circuit lead, and apply 0.2 V voltage; collect the change process of system current with time through the computer data acquisition system.

[0024] Step 3: Place 5 mg of lithium cobalt oxide powder (particle size 8-9 μm) and cathode electrode 5 in 100 mL of deionized water, stir magnetically at 100 rpm for 20 min, and the lithium cobalt oxide particles are completely ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com