Preparation method of resistance random access memory and resistance random access memory

A technology of resistive memory and resistive layer, applied in semiconductor devices, electric solid devices, electrical components, etc., can solve the problems of limiting the application range of resistive memory, high cost, increasing manufacturing cost, etc., to achieve good characteristics and reliability. , The effect of simple equipment and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

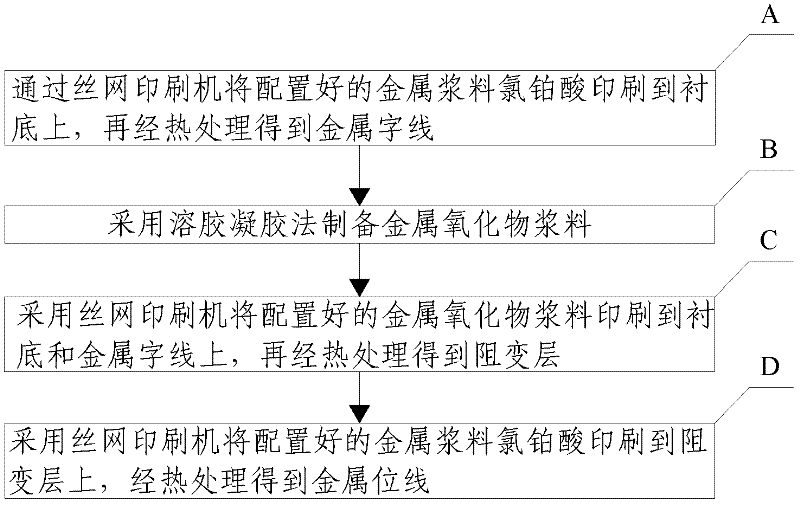

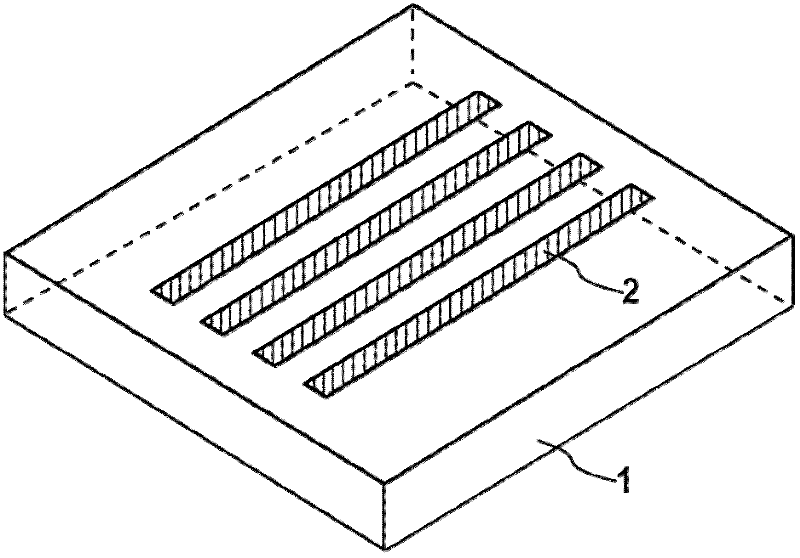

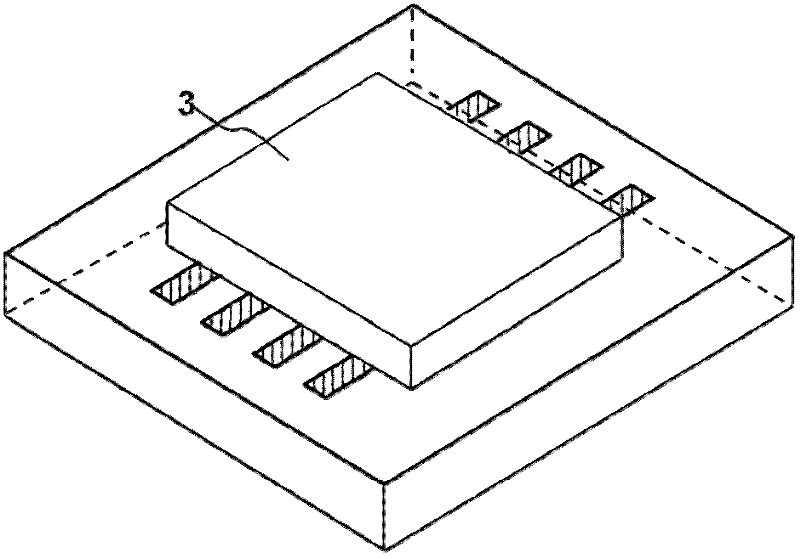

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0032] The cross-array structure of RRAM has been extensively studied, but the method of fabricating 3D structured RRAM using screen printing combined with sol-gel method has not been proposed yet.

[0033] Among them, the basic principle of screen printing is: use the basic principle that the screen graphics part of the mesh is transparent to the slurry, and the non-graphic part of the mesh is impermeable to the slurry for printing. When printing, pour the slurry at one end of the screen, apply a certain pressure on the slurry part of the screen with a scraper, and move towards the other end of the screen at the same time. The slurry is squeezed from the mesh of the grap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap