Rare earth catalyst used in preparation of syngas through biomass and coal in supercritical water in co-gasification mode

A technology of supercritical water gasification and rare earth catalysts, which is applied in the fields of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, inorganic chemistry, etc., and can solve the problems of little research and low carbon monoxide content. Achieve the effects of easy handling, easy pressure control and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

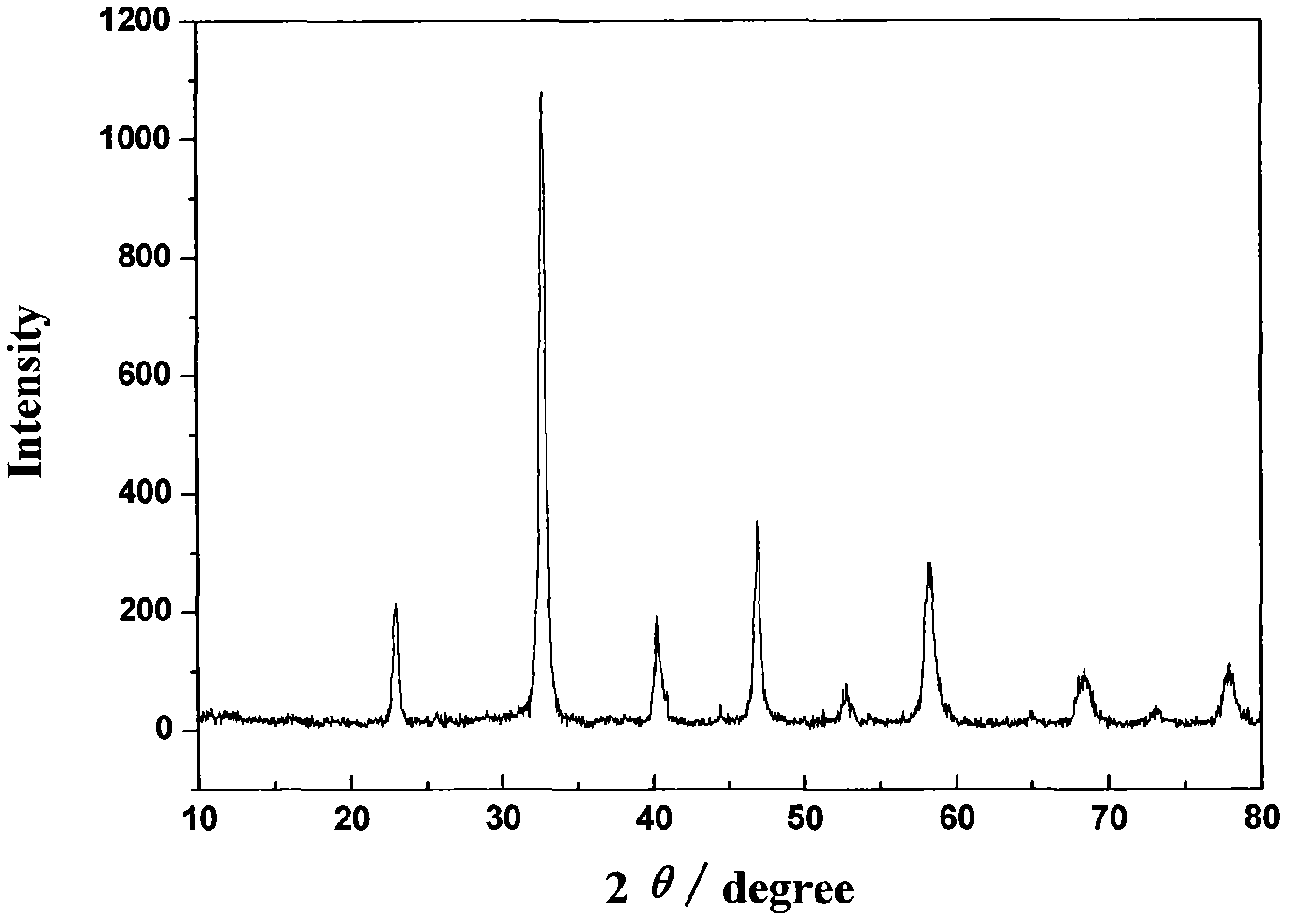

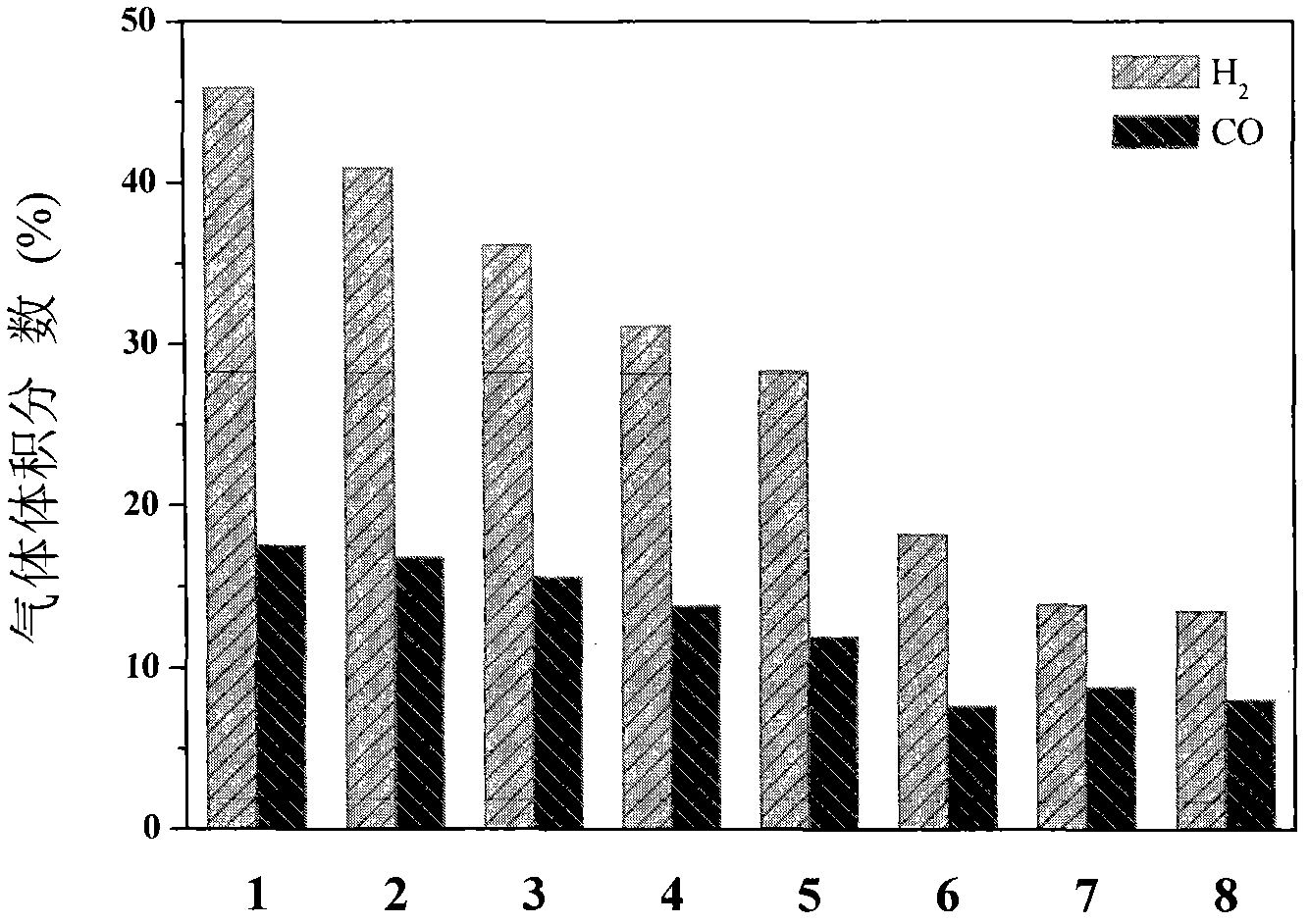

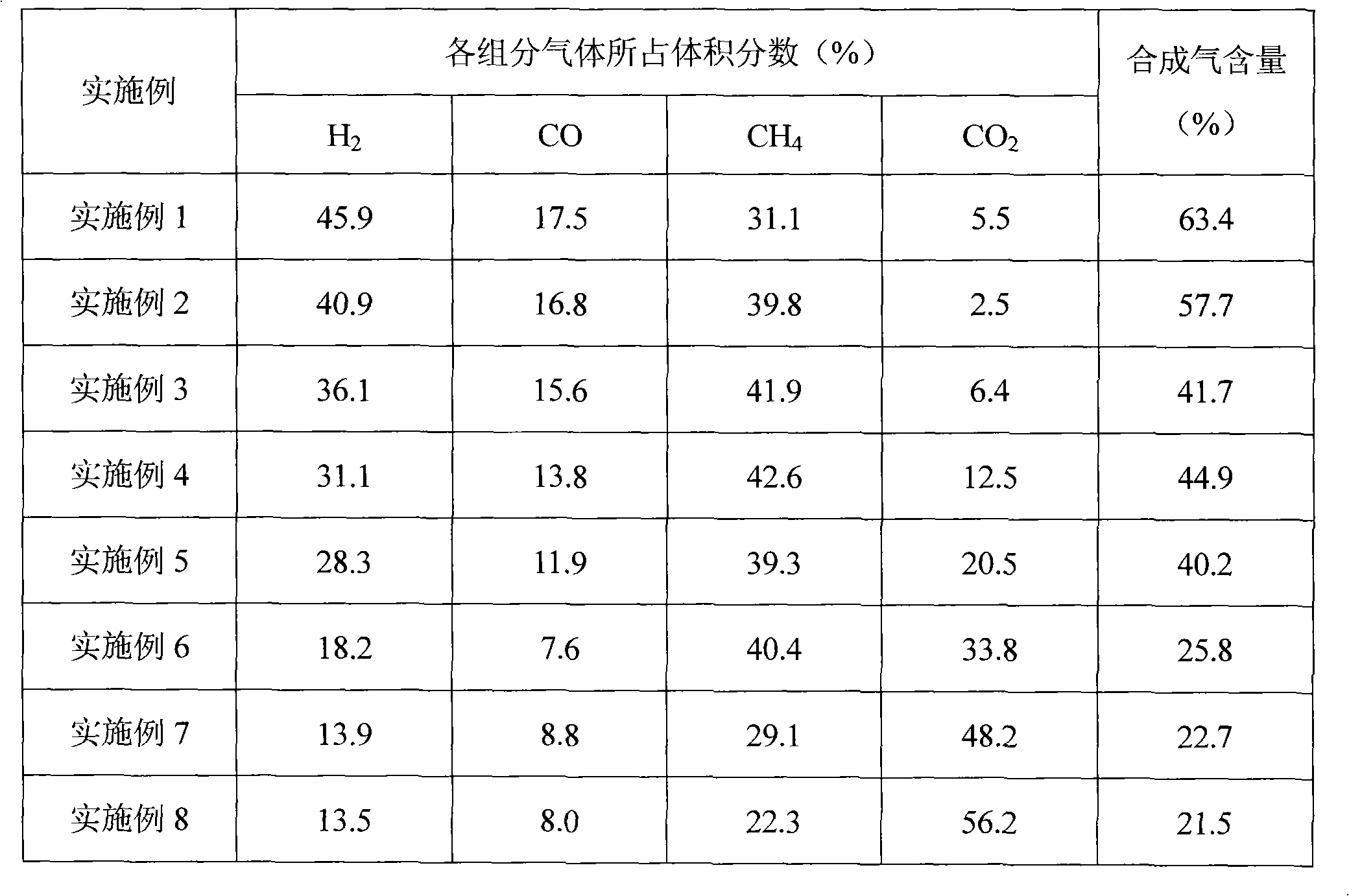

Embodiment 1

[0017] Example 1: 13.00g La (NO 3 ) 3 ·nH 2 O, 5.82g Co(NO 3 ) 2 ·6H 2 O and 7.16g 50%Mn (NO 3 ) 2 The solution was dissolved in deionized water to make a metal nitrate aqueous solution, and then 31.7g of glucose was dissolved in deionized water to form a solution. After mixing the two solutions, the water was evaporated in a constant temperature water bath at 70 °C to form a viscous sol. Dry in the atmosphere for 24h to obtain the dry gel precursor, then calcinate in a muffle furnace at 500℃ for 3h to decompose the organic matter, and finally calcinate at 700℃ in an air atmosphere for 3h to obtain the sample, and the obtained catalyst is used for the synthesis of biomass and coal in supercritical water. Co-gasification reaction. 1.40g biomass, 0.35g coal, 70ml water and 0.35g catalyst were weighed and sieved, and the reaction temperature was controlled at 500°C, the pressure was at 25MPa, and the reaction time was 120min. The experimental operation process is as follo...

Embodiment 2

[0018] Example 2: The catalyst preparation process was the same as that in Example 1, and the obtained catalyst was used for the co-gasification reaction of biomass and coal in supercritical water. Weigh 1.60g biomass, 0.40g coal, add 80ml water, 0.4g catalyst, the reaction temperature is controlled at 450°C, the pressure is 25MPa, the reaction time is 120min, and the operation process is the same as in Example 1.

Embodiment 3

[0019] Example 3: The catalyst preparation process was the same as in Example 1. The obtained catalyst was used for the co-gasification reaction of biomass and coal in supercritical water. 1.60g of biomass and 0.40g of coal were weighed, and 80ml of water and 0.4g of catalyst were added to the reaction. The reaction temperature was controlled at 450° C., the pressure was at 25 MPa, and the reaction time was 90 min. The operation process was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com