Method for preparing zinc oxide nanoshuttle

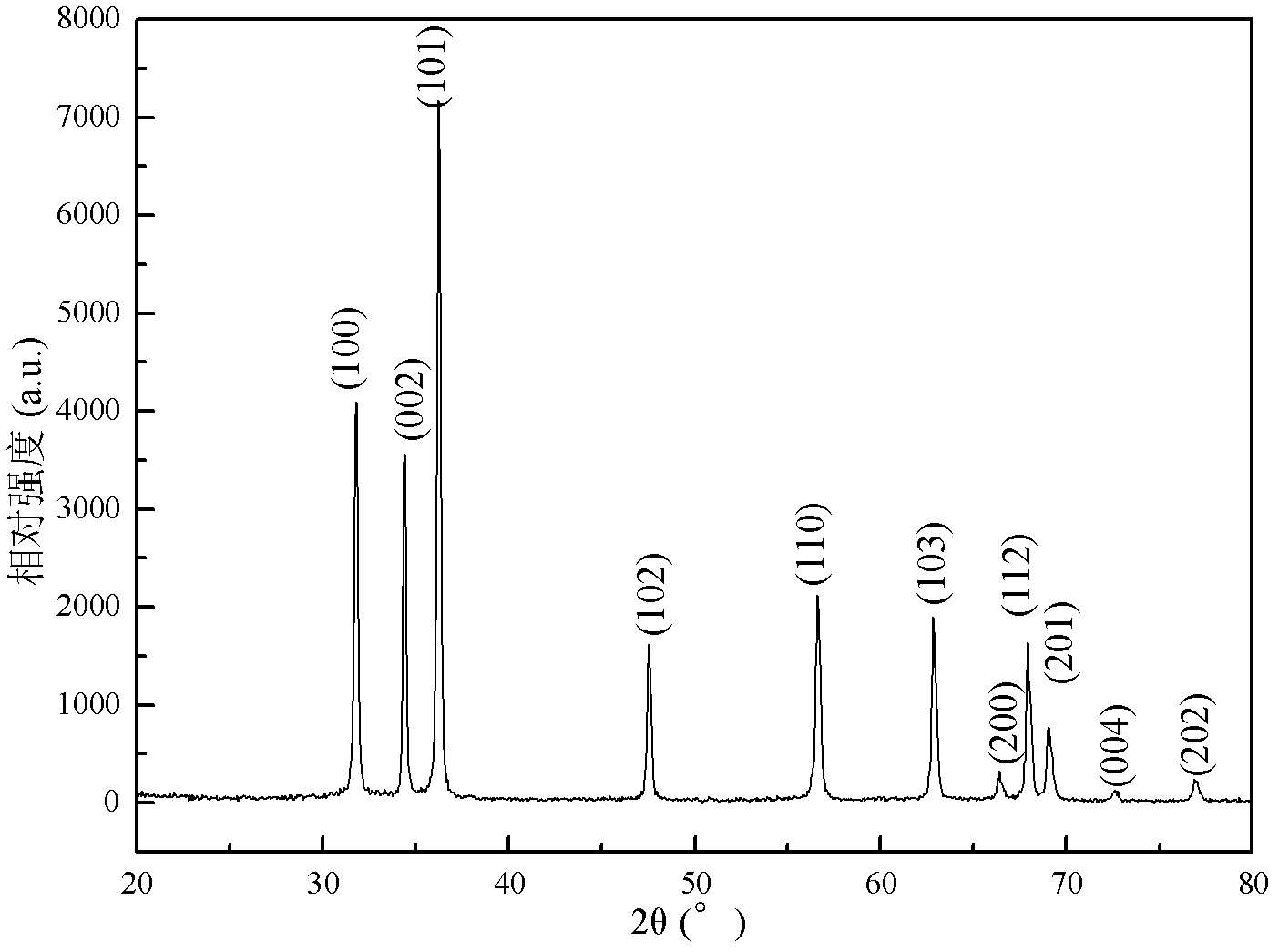

A technology of zinc oxide nano and zinc nitrate, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of high cost, complex equipment, high reaction temperature, etc., and achieve pure crystallization, low reaction temperature and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

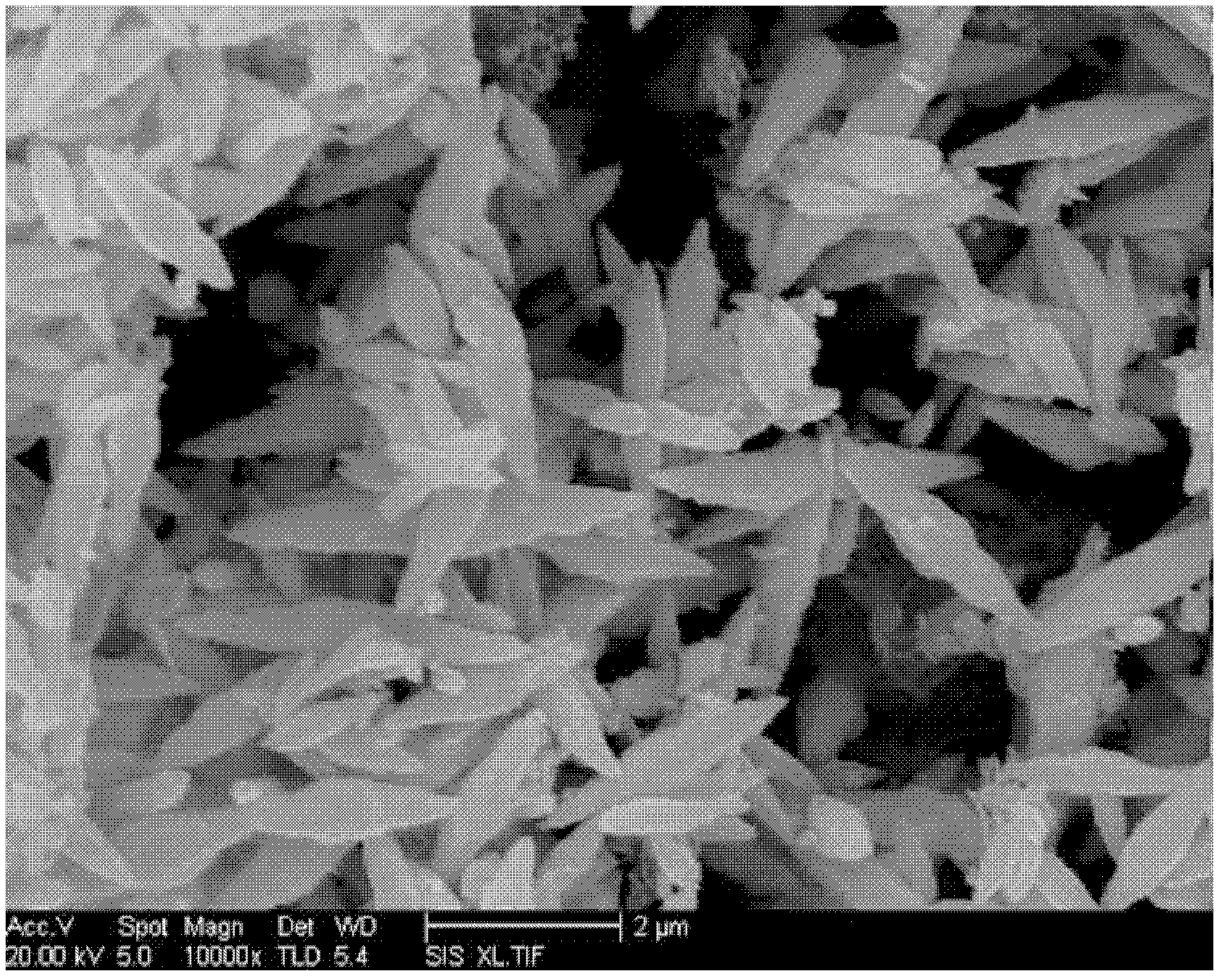

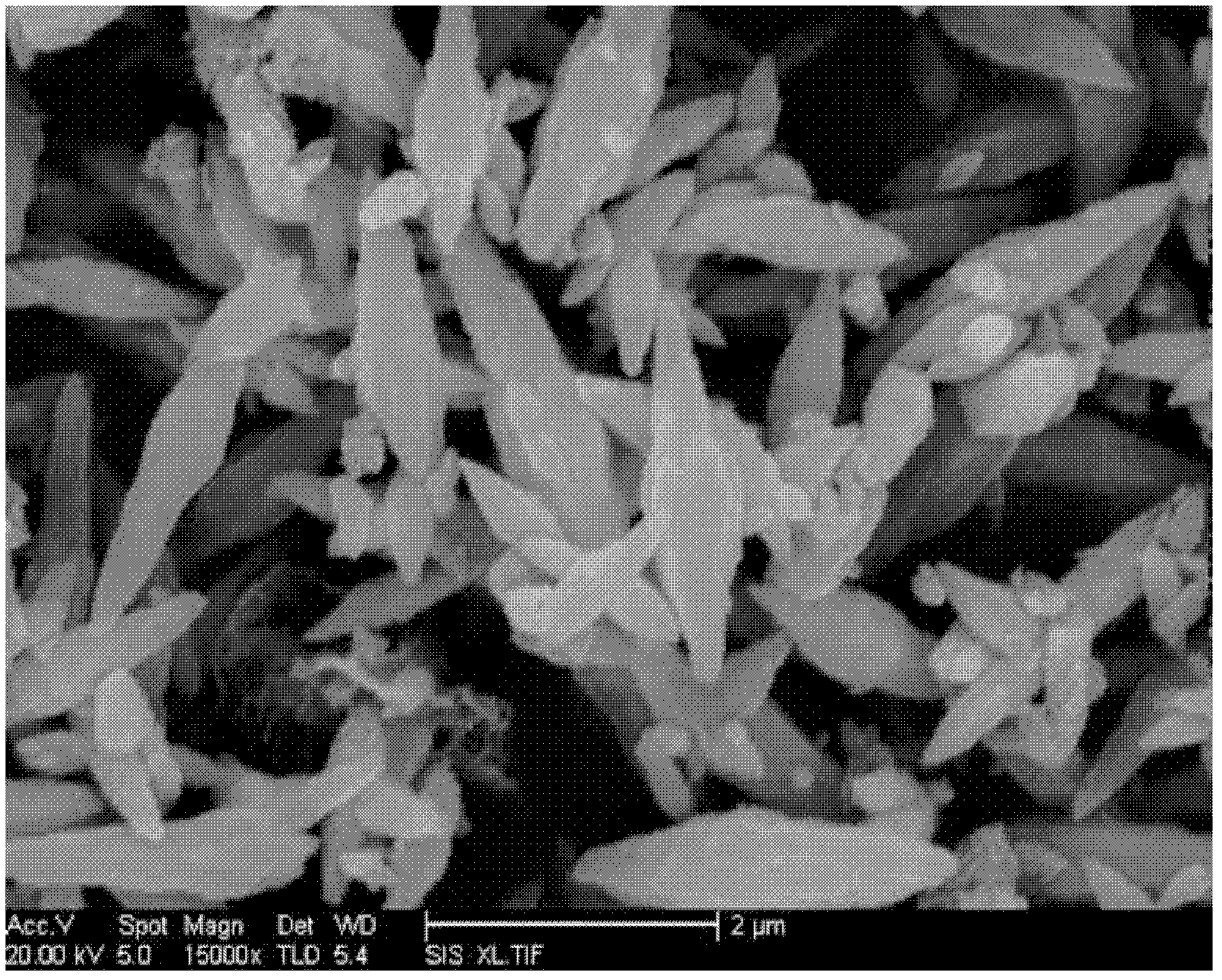

[0014] Specific embodiment one: the method for preparing zinc oxide nano-shuttle in the present embodiment is as follows:

[0015] Step 1, the Zn(NO of 0.005mol 3 ) 2 ·6H 2 The hexamethylenetetramine of 0 and 0.005mol is added into the distilled water of 25ml respectively and stirred and dissolved, and zinc nitrate solution and hexamethylenetetramine solution are obtained;

[0016] Step 2, slowly drop the zinc nitrate solution into the hexamethylenetetramine solution, stir while adding dropwise, then add dropwise 10ml of ammonia solution with a mass concentration of 25%, and then seal the obtained mixed solution;

[0017] Step 3, stirring the mixed solution on a magnetic stirrer at a speed of 300 rpm for 3 to 5 minutes to obtain a transparent and clear solution;

[0018] Step 4. Pour the clarified solution into a stainless steel reactor lined with polytetrafluoroethylene, then place the reactor in a vacuum oven at 130°C, keep it warm for 12-18 hours, then take out the react...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the holding time described in step 4 is 12 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment is different from Embodiment 1 in that the holding time in step 4 is 13 hours. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com