Trimethyl gallium purification system and purification method

A technology of trimethylgallium and purification method, which is applied in the field of purification of metal-organic compounds, to achieve the effects of improving purification efficiency, ensuring safe operation, and simple equipment and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

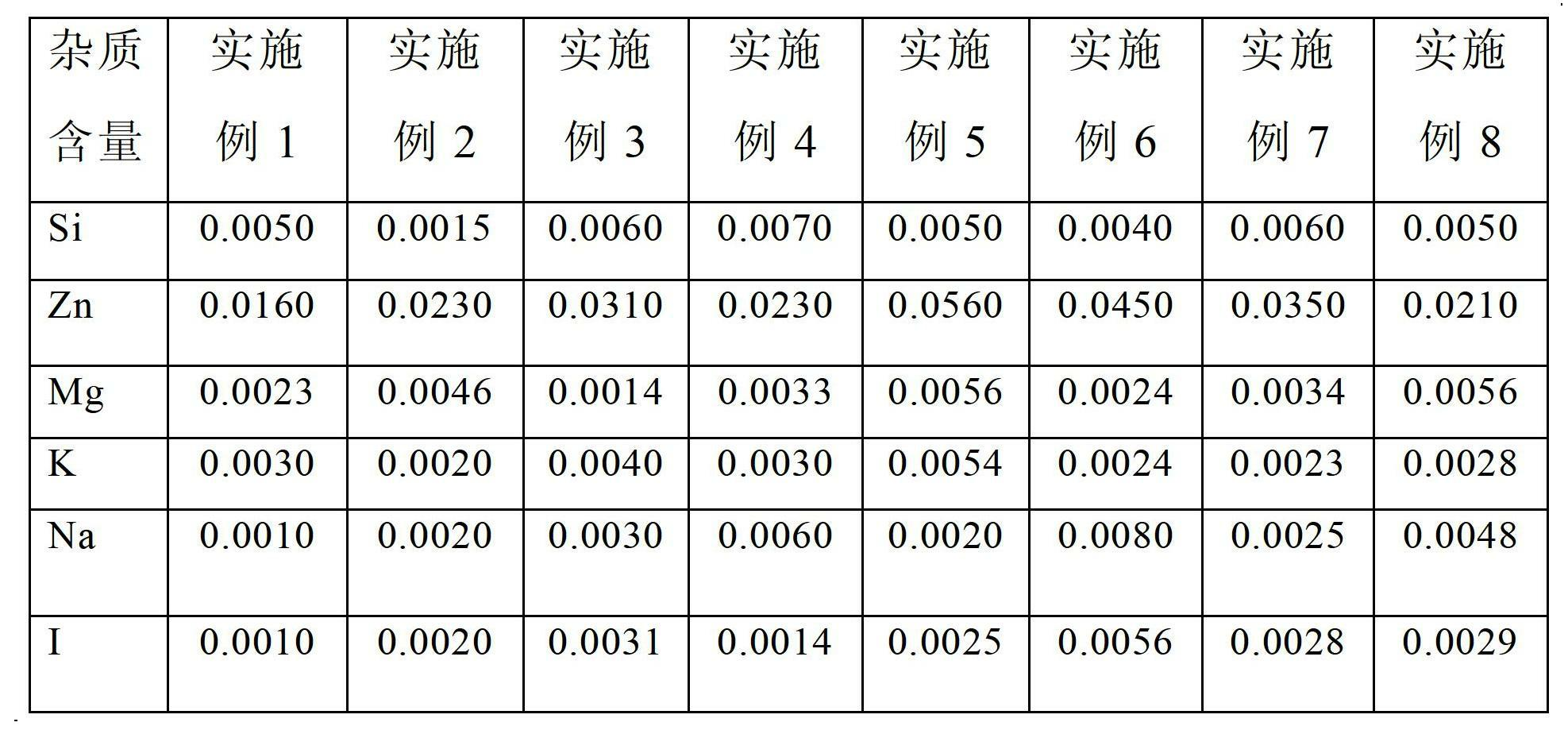

Embodiment 1

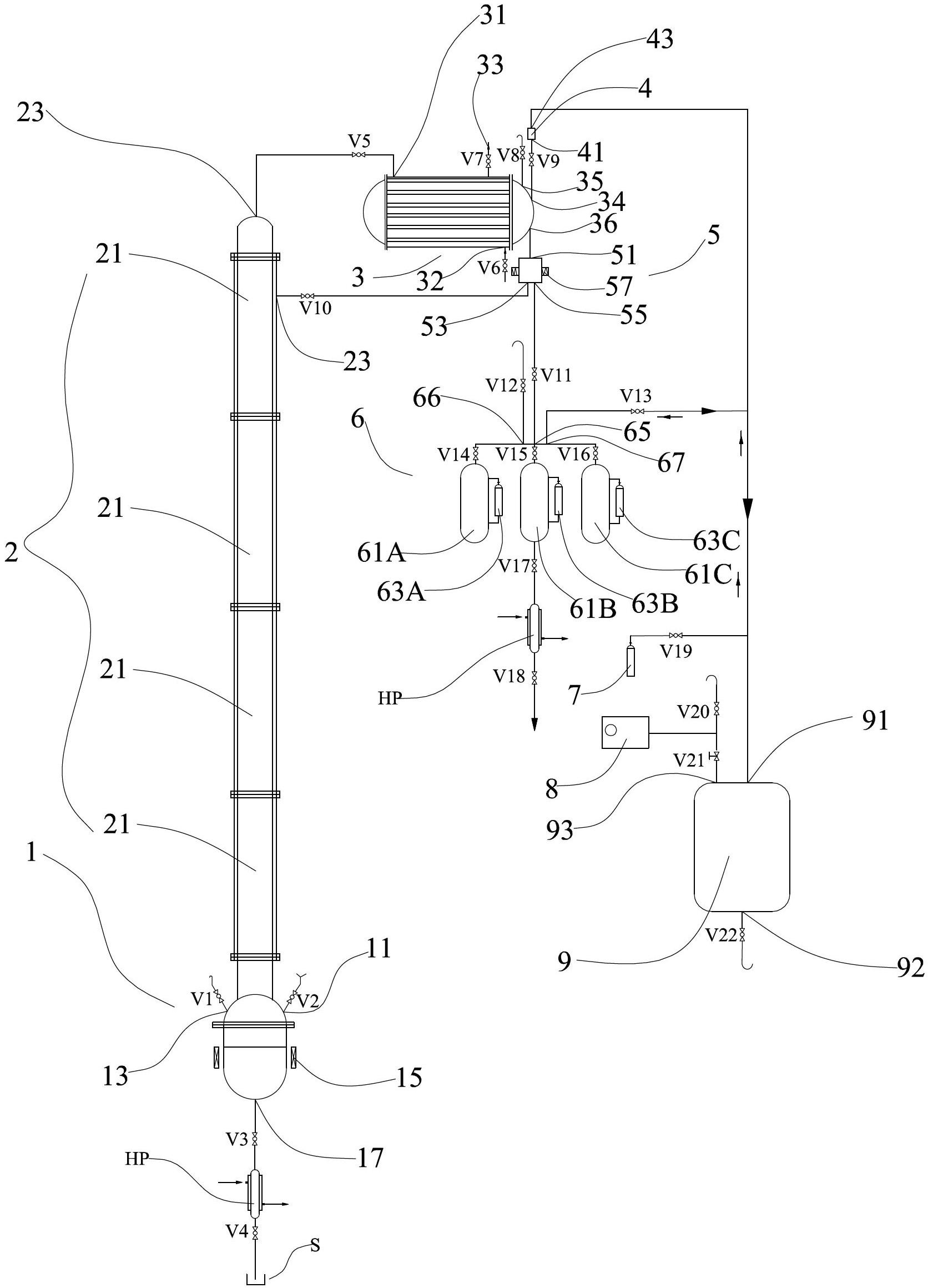

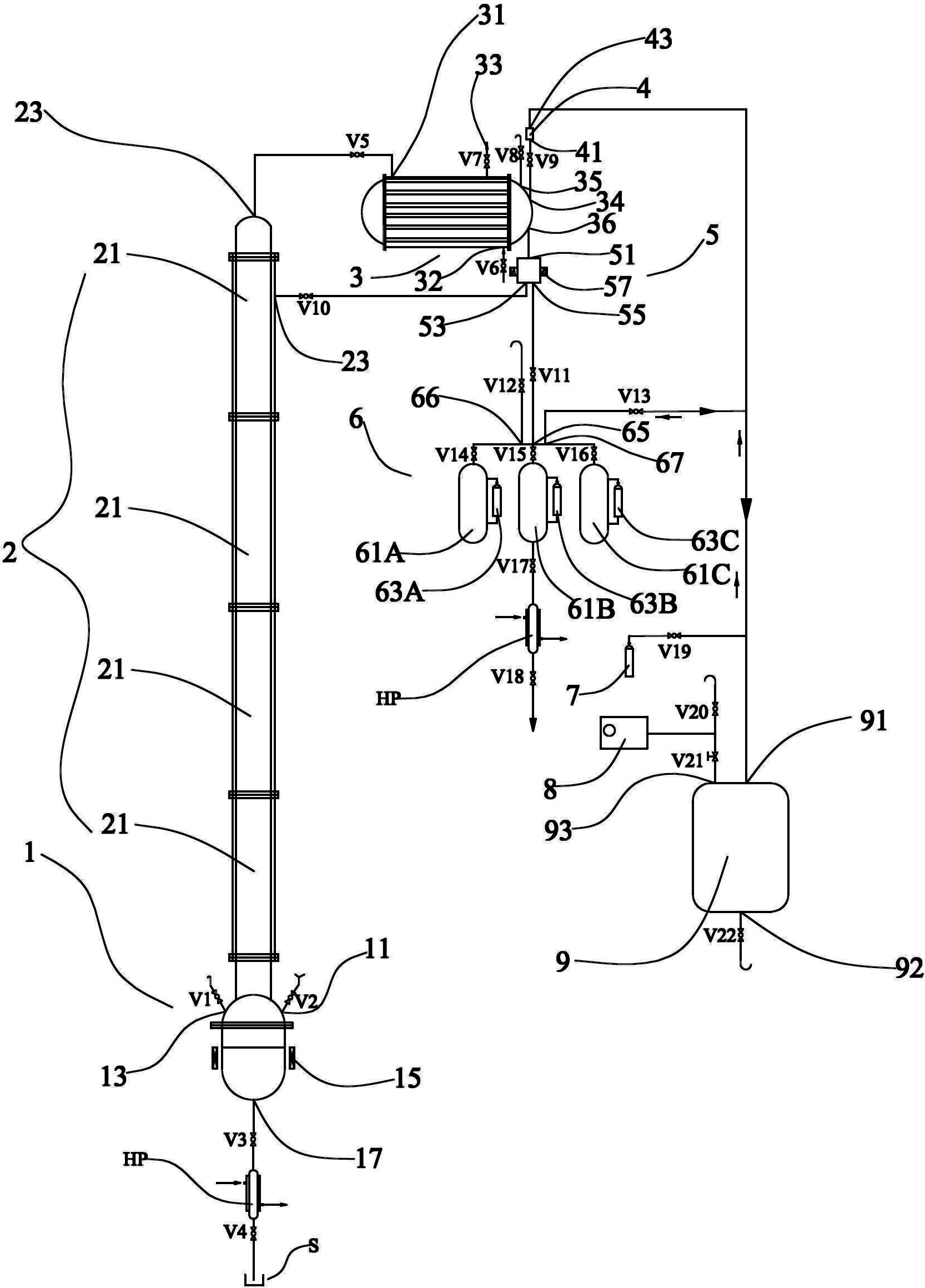

[0053] Through the inert gas supply device 7 using nitrogen and the rotary vane vacuum pump 8 pairs figure 1 The purification system shown (the raw material kettle 1 is a stainless steel batch kettle, the tower column 2 includes four tower sections 21, the condenser 3 uses water as the refrigerant, the cold trap 4 uses water as the refrigerant, and the fraction tank 6 includes The front distillate tank, the middle distillate tank and the rear distillate tank of the earthen tank, and the vacuum buffer tank 9) The whole system has been vacuumed to 10 -1 Pa is then replaced with nitrogen; the 30L trimethylgallium crude product is transferred to the raw material kettle 1 through an inert system using nitrogen, and the column top temperature of the column 2 is controlled at 50 ° C, and the distillation is carried out at atmospheric pressure, and the reflux ratio is 30:1. Middle distillate tank 61B obtains purified trimethylgallium.

Embodiment 2

[0055] Through the inert gas supply device 7 using nitrogen and the rotary vane vacuum pump 8 pairs figure 1 The purification system shown (the raw material kettle 1 is a stainless steel batch kettle, the tower column 2 includes four tower sections 21, the condenser 3 uses water as the refrigerant, the cold trap 4 uses water as the refrigerant, and the fraction tank 6 includes The front distillate tank, the middle distillate tank and the rear distillate tank of the earthen tank, and the vacuum buffer tank 9)) The whole system has been vacuumed to 10 -2 Pa is then replaced with nitrogen; the 30L trimethylgallium crude product is transferred to the raw material kettle 1 through an inert system using nitrogen, and the column top temperature of the column 2 is controlled at 60 ° C, and the distillation is carried out at atmospheric pressure, and the reflux ratio is 40:1. Middle distillate tank 61B obtains purified trimethylgallium.

Embodiment 3

[0057] Through the inert gas supply device 7 using nitrogen and the rotary vane vacuum pump 8 pairs figure 1 The purification system shown (the raw material kettle 1 is a stainless steel batch kettle, the tower column 2 includes four tower sections 21, the condenser 3 uses water as the refrigerant, the cold trap 4 uses water as the refrigerant, and the fraction tank 6 includes The front distillate tank, the middle distillate tank and the rear distillate tank of the earthen tank, and the vacuum buffer tank 9)) The whole system has been vacuumed to 10 -3 Pa is then replaced with nitrogen; the 30L trimethylgallium crude product is transferred to the raw material kettle 1 through an inert system using nitrogen, and the column top temperature of the column 2 is controlled at 70 ° C, and the distillation is carried out at atmospheric pressure, and the reflux ratio is 50:1. Middle distillate tank 61B obtains purified trimethylgallium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com