Preparation method of large-size polymer hollow microspheres with high crosslinking degrees

A technology of hollow microspheres and high cross-linking degree, which is applied in the field of preparation of high-cross-linking degree hollow polymer microspheres and high-cross-linking degree polymer hollow microspheres, can solve problems such as unclean cavities, and avoid unnecessary problems. Stable, diameter-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

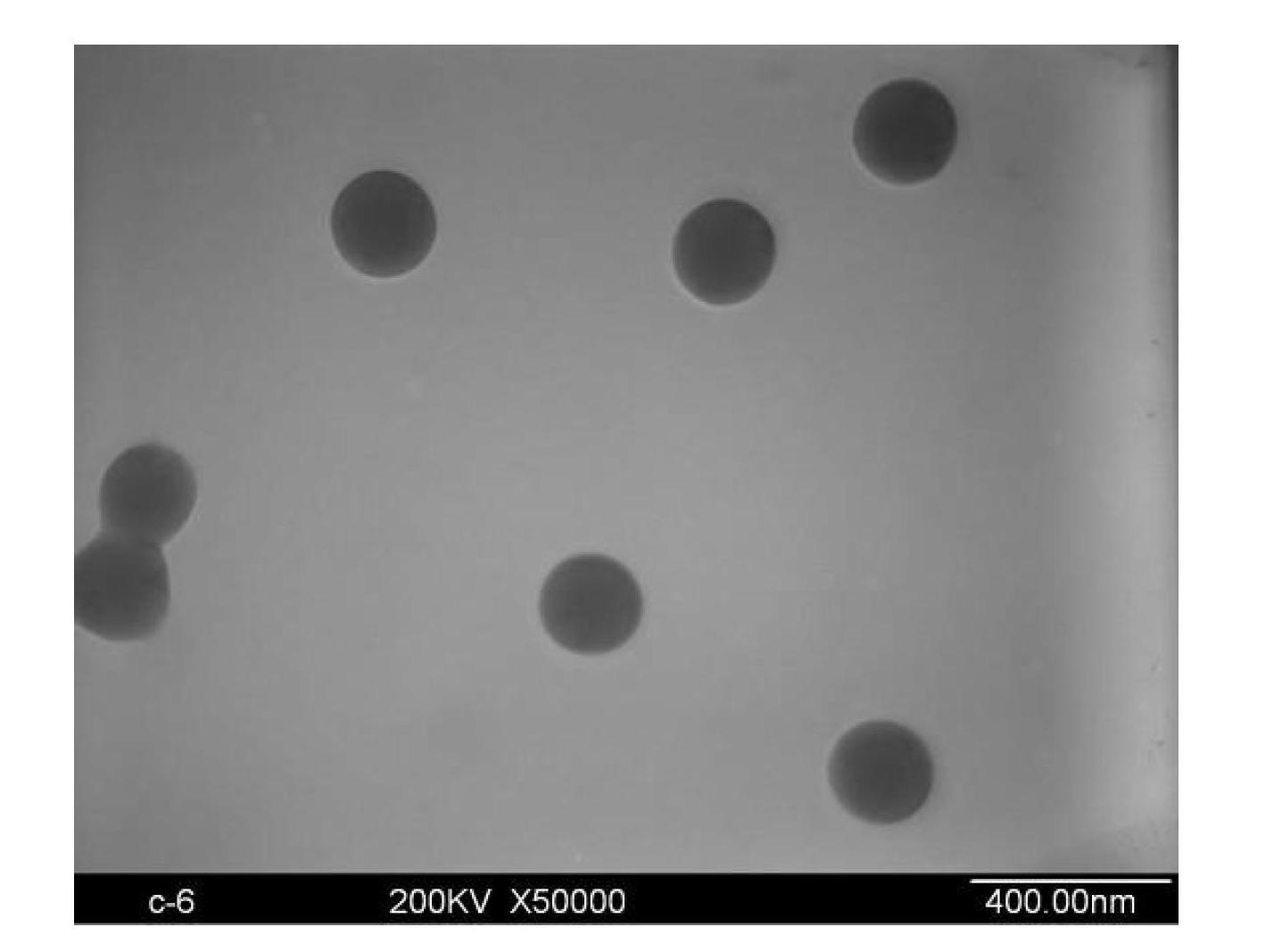

example 1

[0019] (1) Preparation of seed emulsion: Add 0.15g of emulsifier sodium dodecyl biphenyl sulfonate (DSB) and 260g of deionized water to a 500ml four-port tube equipped with stirring, reflux condenser, thermometer and nitrogen inlet tube In the bottle, after stirring for 10 minutes, add 21g methyl methacrylate (MMA), 7.5g butyl methacrylate (BA), 1.5g methacrylic acid (MAA) mixed monomer; heat up to 70°C, add 0.165g An aqueous solution of ammonium persulfate (APS) and 5 g of water and an aqueous solution of 0.075 g of sodium bisulfite (SBS) and 5 g of water were incubated for 2 hours to obtain seed latex particles, which were cooled for later use.

[0020] (2) Preparation of core latex particles: Add 25g of seed latex particles and 185g of deionized water into a 500ml four-necked bottle equipped with stirring, reflux condenser, thermometer and nitrogen inlet tube, and 40.5g of methyl methacrylate (MMA ), 22.5g butyl methacrylate (BA) and 27g methacrylic acid (MAA) were mixed, 0...

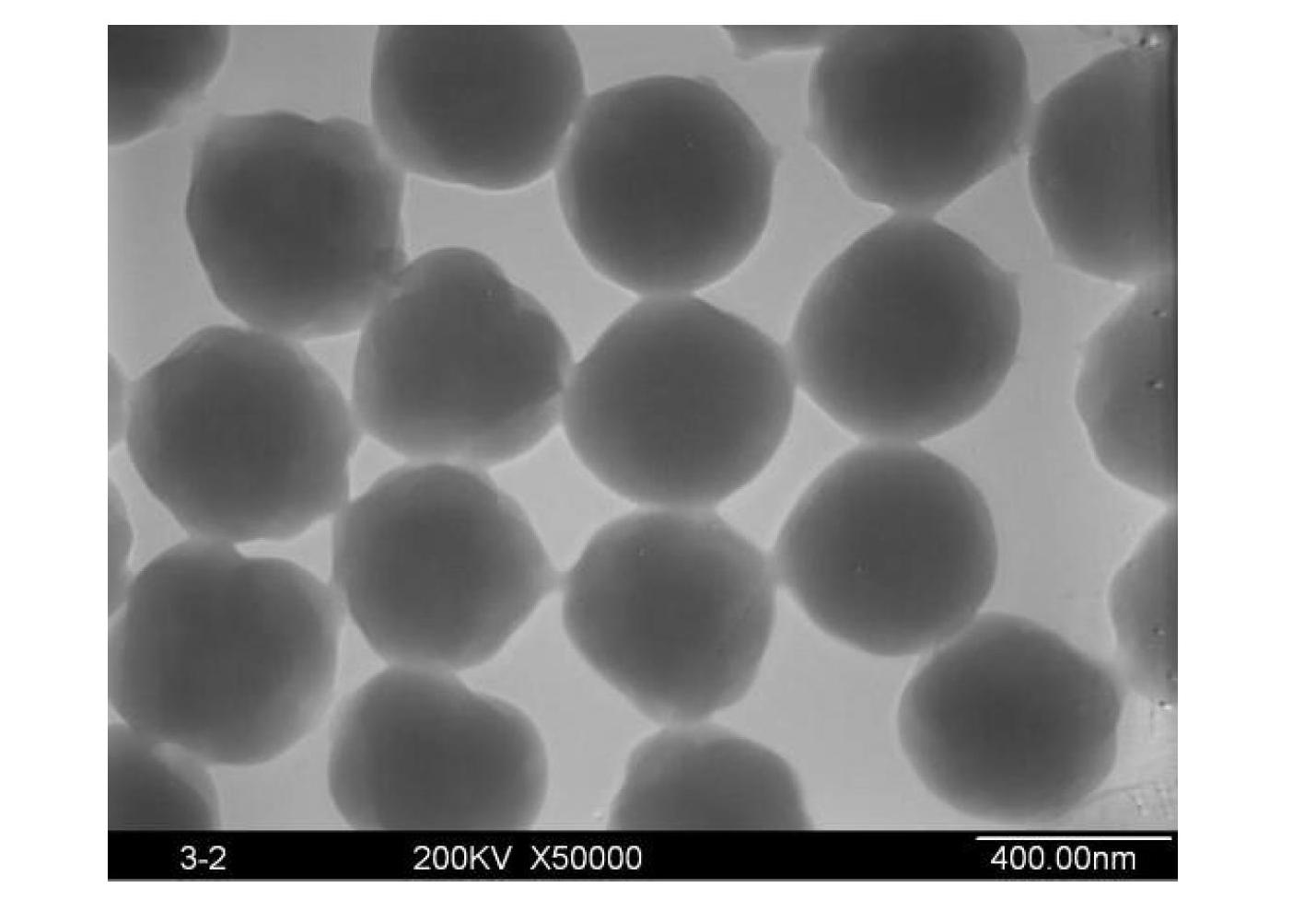

example 2

[0026] (1) Preparation of seed latex particles: same as Example 1.

[0027](2) Preparation of core latex particles: Add 25g of seed latex particles and 185g of deionized water into a 500ml four-necked bottle equipped with stirring, reflux condenser, thermometer and nitrogen inlet tube, and 40.5g of methyl methacrylate (MMA ), 22.5g butyl methacrylate (BA), 27g methacrylic acid (MAA) and 0.09g tripropylene glycol diacrylate (TPGDA) mixed, 0.6188g ammonium persulfate (APS), 0.2813g sodium sulfite (SBS) and 20g of deionized water was mixed, and the temperature was raised to 70°C. At the same time, the monomer mixed solution and the initiator mixed solution were added dropwise, and the drop was completed in 2 hours, and then incubated for 2 hours to obtain the core layer latex particles, and the temperature was lowered for later use.

[0028] (3) Preparation of core-shell latex particles: 75g of core layer latex particles and 128.75g of deionized water were added to a 500ml four-n...

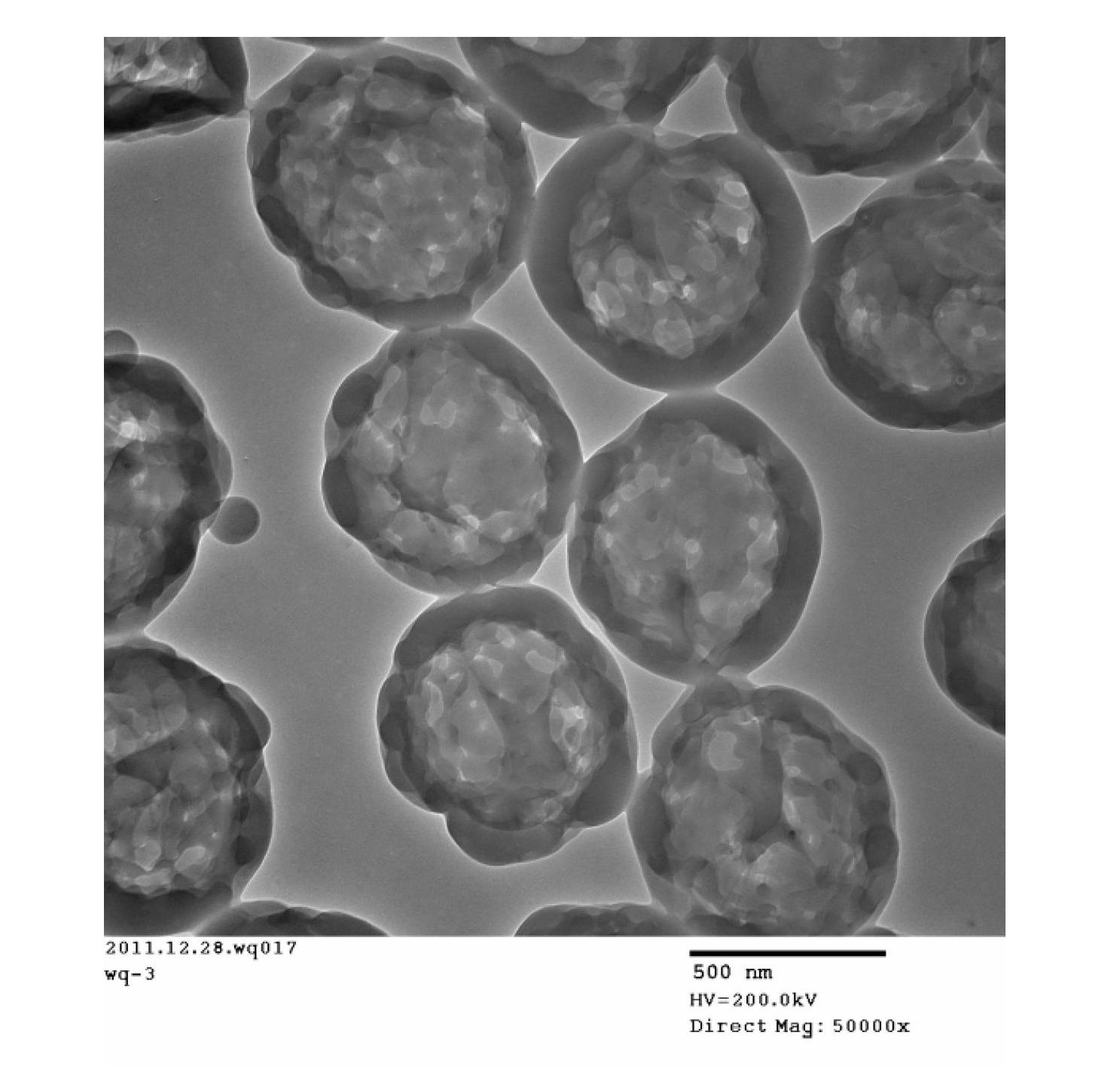

example 3

[0033] (1) Preparation of seed latex particles: same as Example 1.

[0034] (2) Preparation of core layer latex particles: same as example 2

[0035] (3) Preparation of core-shell latex particles: 60g of core layer latex particles and 140g of deionized water were added to a 500ml four-necked bottle equipped with stirring, reflux condenser, thermometer and nitrogen inlet tube, and 54g of styrene (St) , 6g butyl methacrylate (BA) and 0.6g tripropylene glycol diacrylate (TPGDA) mixed, 0.4125g ammonium persulfate (APS), 0.1875g sodium sulfite (SBS) + 0.06g sodium dodecyl biphenyl sulfonate (DSB) was mixed with 20g of deionized water respectively, and the temperature was raised to 70°C. At the same time, the monomer mixed solution and the initiator mixed solution were added dropwise, and the drop was completed in 2 hours, and then continued to heat and mature for 2 hours to obtain core-shell latex particles, which were cooled for later use.

[0036] (4) Alkali / acid gradual expansi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com