Ion nanometer material with fluid behavior at room temperature and preparation method thereof

A technology of nanomaterials and fluids, applied in the field of ionic nanomaterials and its preparation, to achieve good manufacturability and simple preparation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

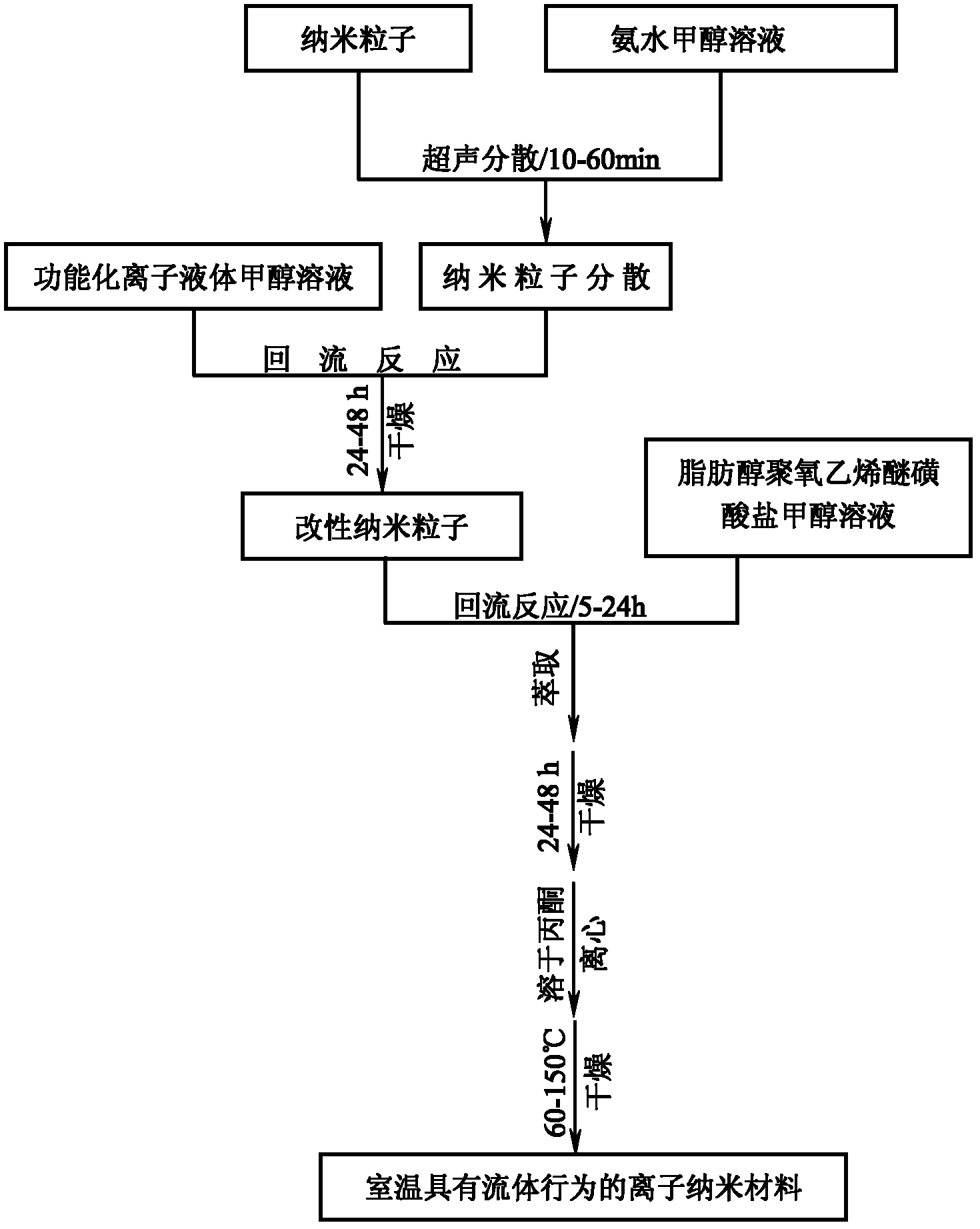

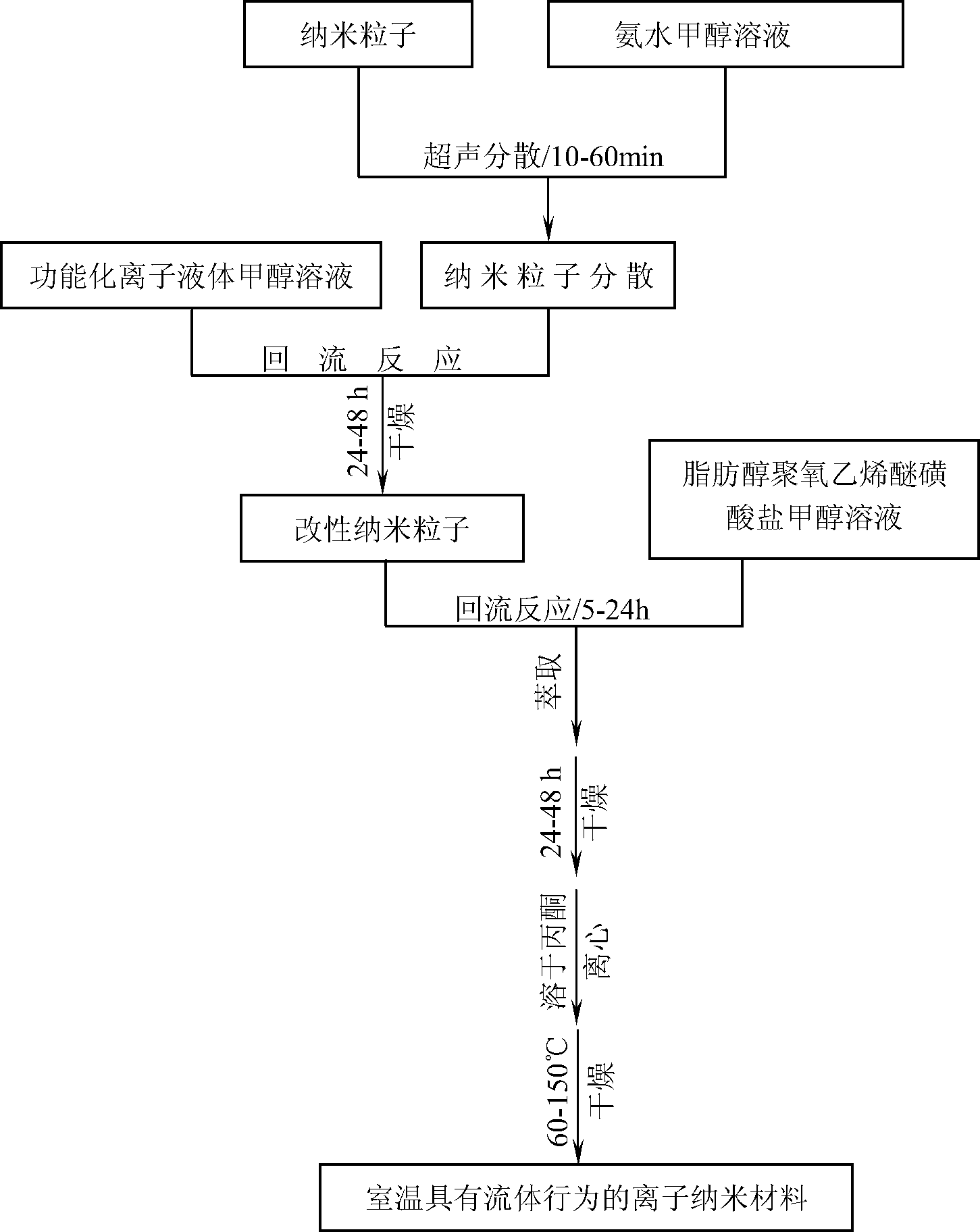

Method used

Image

Examples

Embodiment 1

[0021] Take 1g of titanium dioxide with a particle size of ≤50nm and disperse it in 10g of ammonia water methanol solution (pH=7), sonicate for 30min, add 6g of functionalized ionic liquid [(CH 3 O) 3 Si(CH 2 ) 3 (C 5 h 9 NO)] + Cl - Methanol solution, reflux reaction for 7 hours, the product was repeatedly washed with methanol, and vacuum-dried to constant weight; the dried product was dissolved in tetrahydrofuran, and allowed to stand for 5 minutes, the upper suspension was taken, and vacuum-dried to constant weight; the dried product was added to a concentration of 40g 8% (mass ratio) of C 9 h 19 -C 6 h 4 -(OCH 2 CH 2 ) 20 (CH 2 ) 3 SO 3 - K + Methanol solution, reacted at 70±10°C for 24 hours, extracted the product with toluene, dried in vacuum to constant weight; then dispersed in 15g deionized water, extracted repeatedly with toluene, dried in vacuum to constant weight; dispersed the dried product in acetone , centrifuged, and vacuum-dried to constant ...

Embodiment 2

[0023] Take 1g of titanium dioxide with a particle size of ≤50nm and disperse it in 10g of ammonia methanol solution (pH=10), ultrasonicate for 30min, and add 6g of functionalized ionic liquid [(CH 3 O) 3 Si(CH 2 ) 3 (C 5 h 9 NO)] + Cl - Methanol solution, reflux reaction for 7 hours, the product was washed repeatedly with methanol, and vacuum-dried to constant weight; the dried product was dissolved in tetrahydrofuran, and left to stand for 5 minutes, and the upper suspension was taken, and vacuum-dried to constant weight; the dried product was added to a concentration of 15g 15% (mass ratio) of C 9 h 19 -C 6 h 4 -(OCH 2 CH 2 ) 20 (CH 2 ) 3 SO 3 - K + Methanol solution, react at 70±10°C for 24 hours, extract the product with toluene, dry in vacuum to constant weight; then disperse in 20g deionized water, extract repeatedly with toluene, dry in vacuum to constant weight; disperse the dried product in acetone , centrifugal separation, and vacuum drying to con...

Embodiment 3

[0025] Take 1g of titanium dioxide with a particle size of ≤50nm and disperse it in 20g of ammonia water methanol solution (pH=12), sonicate for 30min, add 3g of functionalized ionic liquid [(CH 3 O) 3 Si(CH 2 ) 3 (C 5 h 9 NO)] + Cl - Methanol solution, reflux reaction for 7 hours, the product was washed repeatedly with methanol, and vacuum-dried to constant weight; the dried product was dissolved in tetrahydrofuran and left to stand for 5 minutes, the upper layer suspension was taken, and vacuum-dried to constant weight; the dried product was added to a concentration of 8g 20% (mass ratio) of C 9 h 19 -C 6 h 4 -(OCH 2 CH 2 ) 20 (CH 2 ) 3 SO 3 - K+ Methanol solution, react at 70±10°C for 24 hours, extract the product with toluene, dry it in vacuum to constant weight; then disperse it in 25g deionized water, extract it repeatedly with toluene, dry it in vacuum to constant weight; disperse the dried product in acetone , centrifuged, and vacuum-dried to constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com