Preparation method of ferric oxide-doped mesoporous molecular sieve smoke suppressant

A technology of mesoporous molecular sieve and iron oxide, which is applied in the direction of fire-resistant coatings, etc., can solve the problems of not many applications in the field of flame-retardant, and achieve the effect of high specific surface area and stable protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

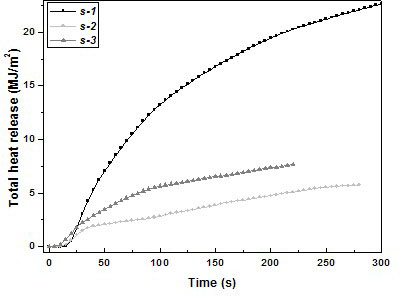

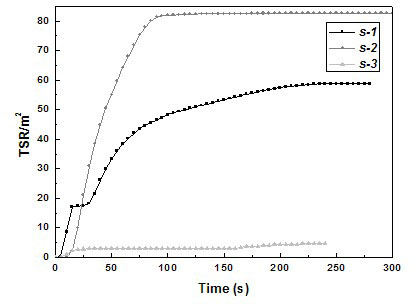

Embodiment 1

[0022] Weigh 17.04g P123 and 14.4g NaCl, add 435ml deionized water and 15mL 37wt% HCI solution, and stir thoroughly at 35°C for 3h. Then slowly add 26.56g of ethyl orthosilicate and 6.06g of vinyltriethoxysilane, and continue to stir for 12h. The above solution is transferred to a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, sealed, 110 o C for 36h, naturally cooled, filtered, and vacuum-dried, the resulting solid powder was heated to 550°C at a rate of 1.0°C / min in a muffle furnace. o C, sintering for 7 hours to remove the P123 template, and obtain a mesoporous molecular sieve with Ia3d mesoporous structure. Weigh 0.845g of ferric chloride hexahydrate, dissolve in 20mL of ethanol and water mixed solution of equal volume ratio, add 2.0g of the above 150 o C The mesoporous molecular sieve after vacuum drying treatment, ultrasonic dispersion 30min, 40 o C is stirred, concentrated and evaporated to remove the solvent, then placed in a reaction furnac...

Embodiment 2

[0024] Weigh 17.04g P123 and 14.4g NaCl, add 435ml deionized water and 15mL 37wt% HCI solution, and stir thoroughly at 35°C for 3h. Then slowly add 26.56g of ethyl orthosilicate and 6.06g of vinyltriethoxysilane, and continue to stir for 24h. The above solution is transferred to a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, sealed, 110 o C for 24 hours, naturally cooled, filtered, and vacuum-dried, the resulting solid powder was heated to 550 °C at a rate of 1.0 °C / min in a muffle furnace. o C, sintering for 7 hours to remove the P123 template, and obtain a mesoporous molecular sieve with Ia3d mesoporous structure. Weigh 0.34g of ferric chloride hexahydrate, dissolve in 20mL of ethanol and water mixed solution of equal volume ratio, add 2.0g of the above 150 o C The mesoporous molecular sieve after vacuum drying treatment, ultrasonic dispersion 30min, 40 o C was stirred, concentrated and evaporated to remove the solvent, then placed in the reacti...

Embodiment 3

[0026] Weigh 11.25g of P123, add 396g of deionized water and 10.8g of NaCl, stir and dissolve at 35°C. Then add 54ml of HCl solution with a concentration of 37wt%, and continue to disperse for 3h, then slowly add 23.4g of ethyl orthosilicate and 6mL of n-butanol, and continue stirring for 24h. The above solution was placed in a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, sealed, and hydrothermally treated at 110°C for 24h. Cool down naturally, filter, and vacuum-dry, and raise the temperature of the obtained solid powder to 550 °C at a rate of 1.0 °C / min in a muffle furnace. o C, sintering for 7 hours to remove the P123 template, and a mesoporous molecular sieve with a P6mm mesoporous structure can be obtained. Weigh 1.01g of ferric nitrate hexahydrate, dissolve in 20mL of ethanol and water mixed solution of equal volume ratio, add 2.0g of the above 150 o C The mesoporous molecular sieve after vacuum drying treatment, ultrasonic dispersion 30min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com