Multistage serially-connected biochemical reaction device and flow type anaerobic fermentation method

A biochemical reaction and series technology, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical cleaning device, etc., can solve the problem of slow growth of anaerobic microorganisms, no industrial value, Anaerobic equipment start-up and processing time are too long to achieve the effect of solving energy shortage, shortening processing time and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

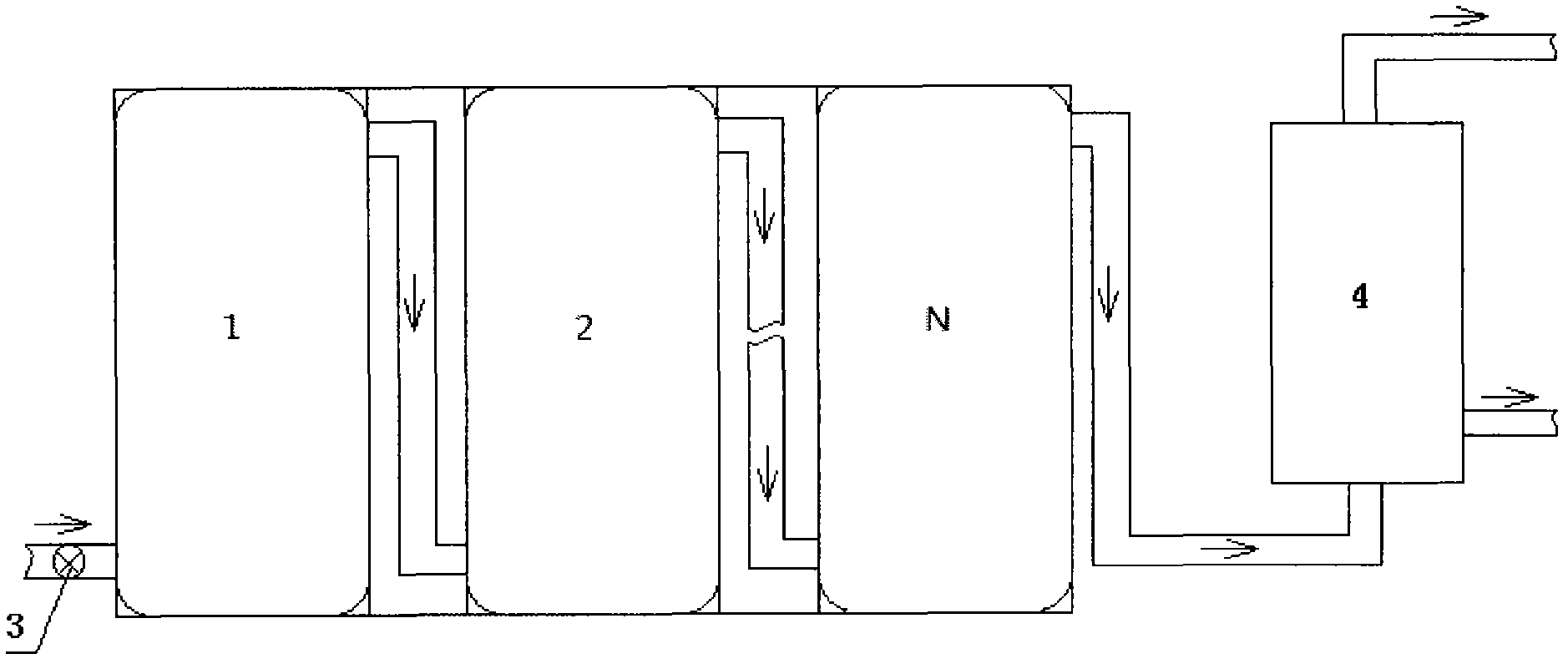

[0035] Such as figure 1 As shown, a multi-stage serial biochemical reaction device includes at least two reaction areas, each reaction area is provided with a biological support, and microorganisms of different strains are attached to the biological supports in different reaction areas. In the same reaction area Microorganisms of the same type of bacteria are attached to the biological support of each reaction zone; inlets and outlets are respectively provided at the lower and upper parts of each reaction zone, and the outlet of the former reaction zone is connected with the inlet of the latter reaction zone through pipelines. The multi-stage serial biochemical reaction device also includes a pump 3, which provides power for raw materials to flow into the multi-stage serial biochemical reaction device from the inlet of the first reaction area 1 of the hydrolysis reaction area, and flows through each reaction area in turn. The outlet of the last reaction zone is connected to th...

Embodiment 2

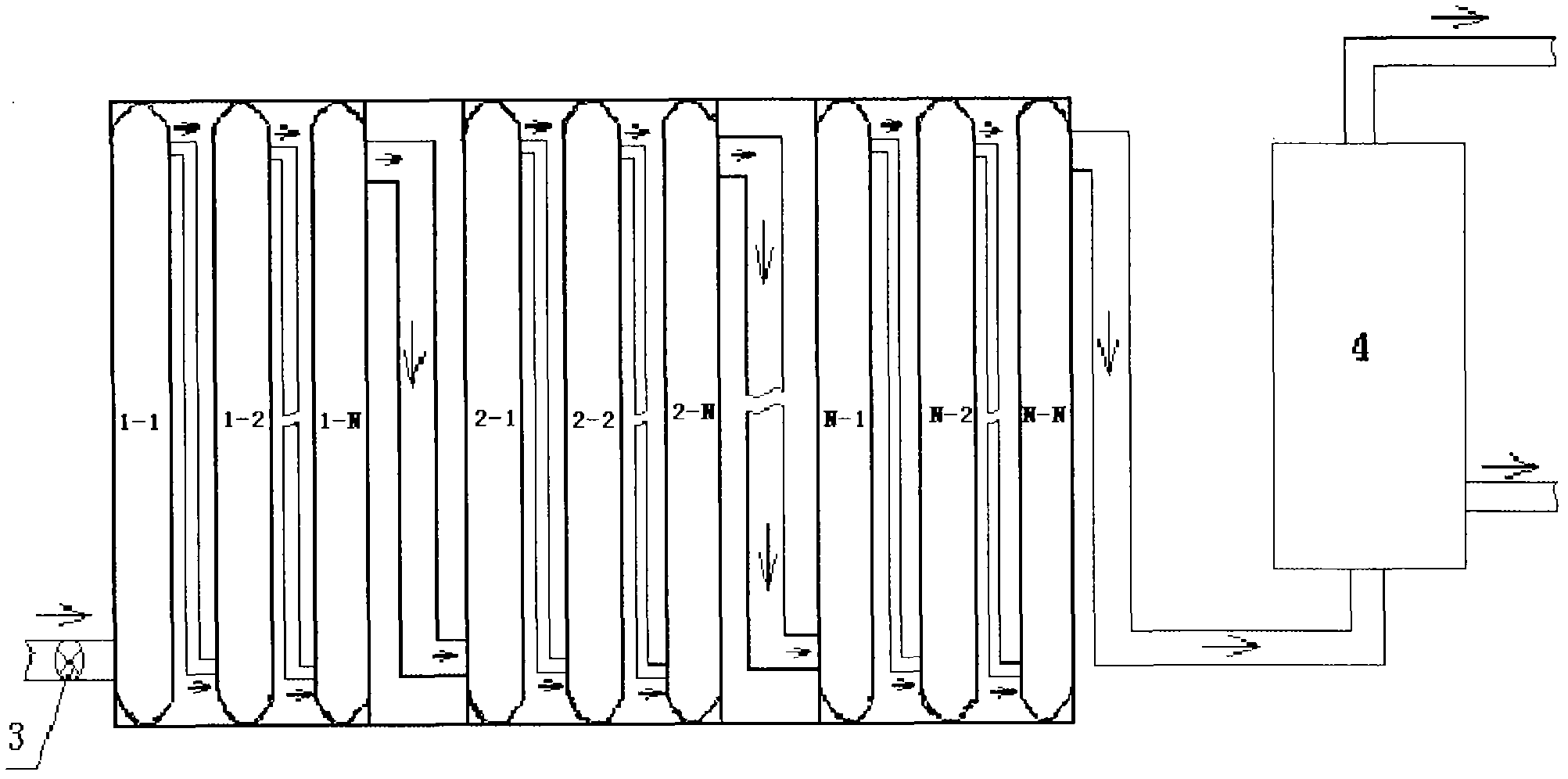

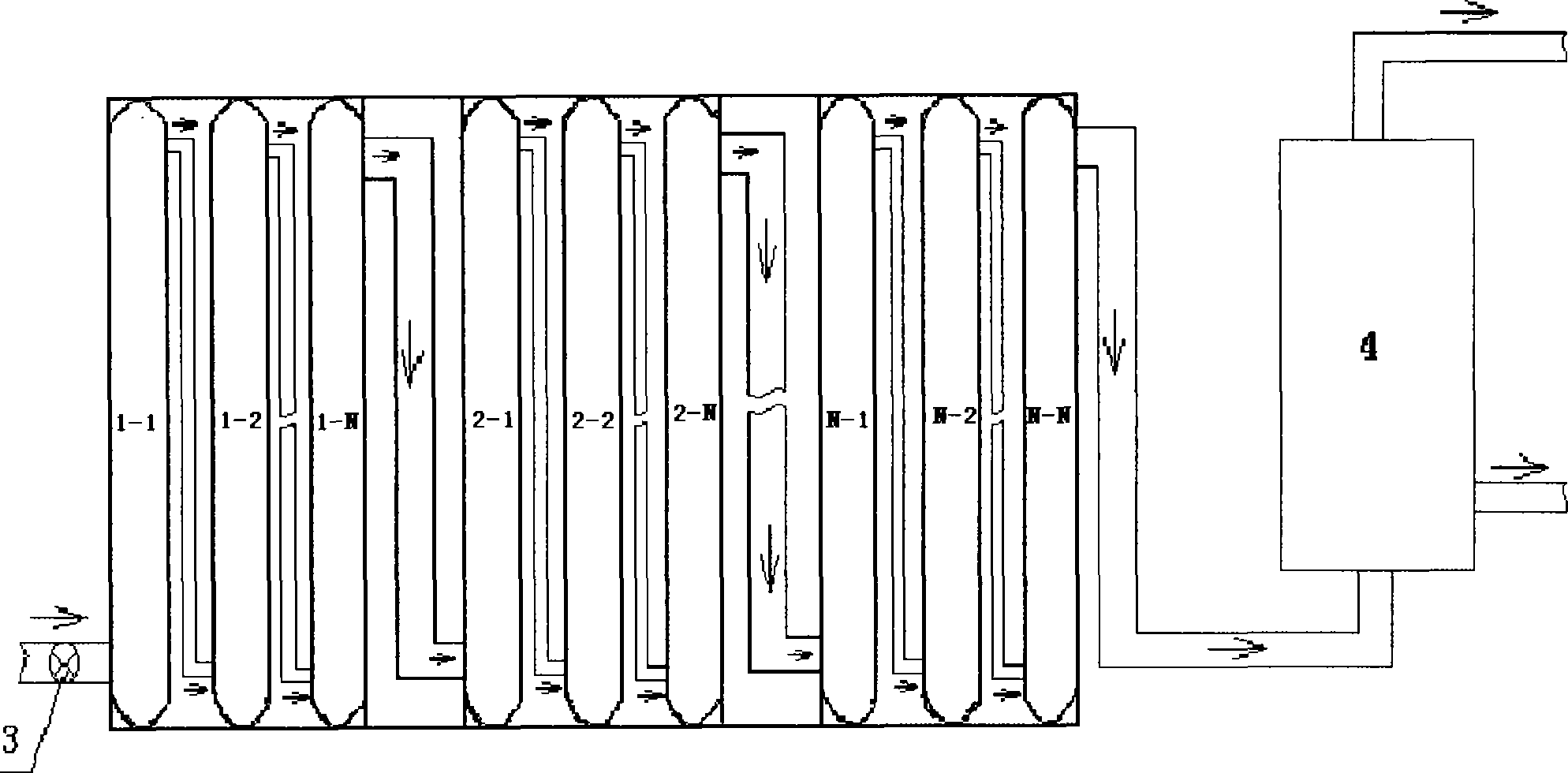

[0037] Such as figure 2 As shown, a multi-stage serial biochemical reaction device includes at least two reaction areas, at least two small reaction areas are arranged in each of the reaction areas, and inlets are respectively provided at the lower and upper parts of each small reaction area and the outlet, the outlet of the former small reaction area is connected with the inlet of the latter small reaction area through pipelines; microorganisms of different types of bacteria are attached to the biological support in different reaction areas, and the organisms in the small reaction area of the same reaction area Microorganisms of the same type of bacteria are arranged on the bracket. The multi-stage serial biochemical reaction device also includes a pump 3, and the pump 3 provides power for the raw material to flow into the multi-stage serial biochemical reaction device from the entrance of the first small reaction area 1-1 in the first reaction area, and flows through the ...

Embodiment 3

[0039] Such as figure 2 As shown, a multi-stage serial biochemical reaction device is used for producing biogas and biogas slurry, and the multi-stage serial biochemical reaction device includes a hydrolysis reaction area, an acidification reaction area and a methane reaction area. In the hydrolysis reaction area, at least two small reaction areas are provided, and an inlet and an outlet are respectively arranged at the bottom and upper part of each small reaction area, and the outlet of the previous small reaction area is connected with the inlet of the latter small reaction area through a pipeline, and the Hydrolytic bacteria are attached to the biological support in each small reaction area of the hydrolysis reaction area; at least two small reaction areas are provided in the acidification reaction area, and inlets and outlets are provided at the lower and upper parts of each small reaction area. The outlet of the small reaction area is connected with the inlet of the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com