Microwave rapid dissolving method for rhodium powder

A rhodium powder, microwave technology, applied in the field of rapid dissolution of rhodium powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment one: self-produced pure rhodium powder 1# (99.95% rhodium sponge)

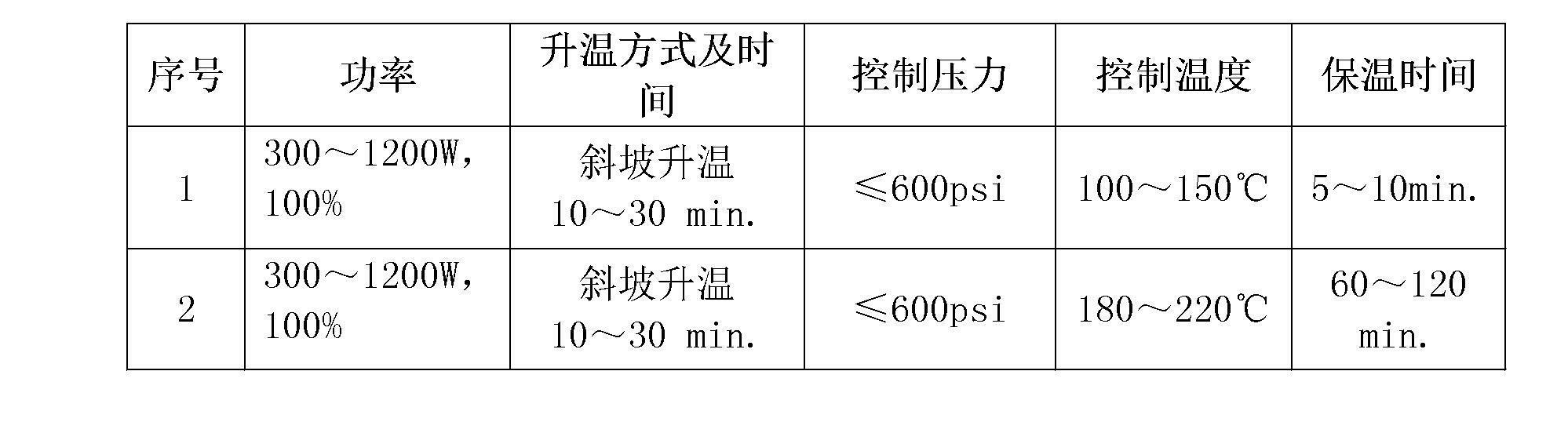

[0023]Weigh 0.3g, put it into an agate mortar and grind it for about 20min, then accurately weigh 0.1000g, put it into a 100mL microwave digestion tank, add 10mL-15mL concentrated HCl, 2mL-5mL 30% over Hydrogen oxide, airtight, dissolve according to the program conditions in Table 1, open the tank to observe after cooling, one program has been completely dissolved. Transfer the solution into a beaker, and finally prepare a pure 1.000mg / mL rhodium standard solution, using YS / T 561-2009 "Methods for Chemical Analysis of Precious Metal Alloys Determination of Rhodium Content in Platinum-Rhodium Alloys" Calibration, the calibration value is 0.9998 mg / mL, which proves that the dissolution is complete.

[0024] In addition, take a little unground pure rhodium powder and ground pure rhodium powder, according to the requirements of GB / T 1421-2004 rhodium powder standard, adopt YS / T 363-2006 emission...

Embodiment 2

[0025] Embodiment two: imported pure rhodium powder 2# (99.98% rhodium powder, coarser particles)

[0026] Weigh 0.3g, put it into an agate mortar and grind it for about 40 min., accurately weigh 0.1000g, put it into a 100 mL microwave digestion tank, add 10 mL~15 mL concentrated HCl, 2 mL~5 mL 30% Hydrogen peroxide, airtight, dissolve according to the program conditions in Table 1, open the tank for observation after cooling, and there is still a little by naked eye observation. Add 2 mL to 5 mL of 30% hydrogen peroxide, seal it tightly, and then dissolve according to the program conditions in Table 1. After cooling, open the tank and observe that it has completely dissolved. Transfer the solution into a beaker, and finally prepare a pure 1.000mg / mL rhodium standard solution, using YS / T 561-2009 "Methods for Chemical Analysis of Precious Metal Alloys Determination of Rhodium Content in Platinum-Rhodium Alloys" Calibration, the calibration value is 0.9999mg / mL, which proves t...

Embodiment 3

[0028] Example 3: High-content rhodium waste 3# (sampled to a particle size of ≤ 150 mesh with a disc mill)

[0029] Accurately weigh 0.1000g, put it into a 100 mL microwave digestion tank, add 10 mL~15 mL concentrated HCl, 2 mL~5 mL 30% hydrogen peroxide, seal it tightly, dissolve according to the program conditions in Table 1, and open the tank after cooling , then add 2 mL ~ 5 mL 30% hydrogen peroxide, airtight, and then dissolve according to the program conditions in Table 1. After cooling, open the can, transfer the solution into a beaker, and finally prepare a 100 mL10% hydrochloric acid medium solution, using YS / T 561-2009 "Chemical Analysis Methods for Precious Metal Alloys Determination of Rhodium Content in Platinum-Rhodium Alloys" Hexaammine Cobalt Nitrate Gravimetric Method "Measuring, the measuring result is that the Rh content is 78.61%. It is 78.58% consistent with the measured value obtained by other dissolution methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com