Catalytic gasification of organic matter in supercritical water

A technology of supercritical water and organic matter, applied in the direction of physical/chemical process catalyst, gasification process, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of incomplete conversion, complex and expensive process equipment, etc. Achieve easy storage and transportation, reduce complexity and cost, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

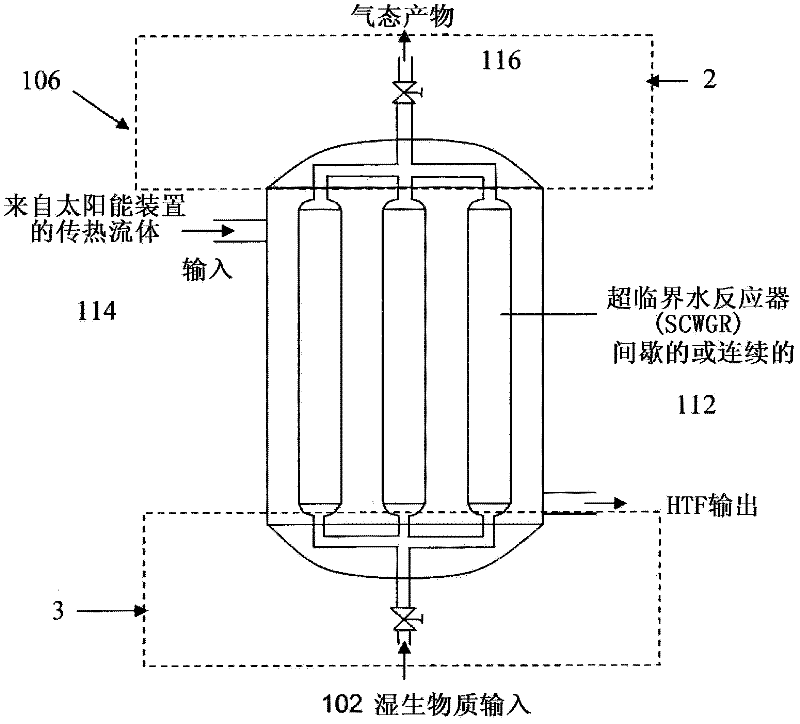

[0083] The present invention provides a suitable catalyst system for converting organic matter with high efficiency and in a relatively short time. It is understood that under SCWG conditions, when known systems of said type are operated for a long time, the efficiency of the catalyst is reduced due to the oxidation of the metal components in the process environment, the sintering of metal particles, the formation of coke and tar, and the decomposition of the matrix.

[0084] Alkaline catalysts (such as sodium carbonate) [9] have been used to increase the gasification efficiency of cellulose. Known such as K 2 CO 3 , KOH, NaOH and Na 2 CO 3 and other bases can also catalyze the water gas shift reaction to form H 2 and CO 2 (instead of CO). Other catalysts such as Pt and Pd with lower activity were also tested. Copper, molybdenum, tungsten, chromium and zinc metals were also tested, although these also showed very low levels of catalytic activity. such as CeO 2 , (CeZr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| isentropic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com