Lutein ester soft candy and production method thereof

A technology of lutein ester and soft candy, which is applied in the direction of confectionery, confectionery industry, food science, etc., can solve the problem of insufficient quantity and achieve the effect of moderate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

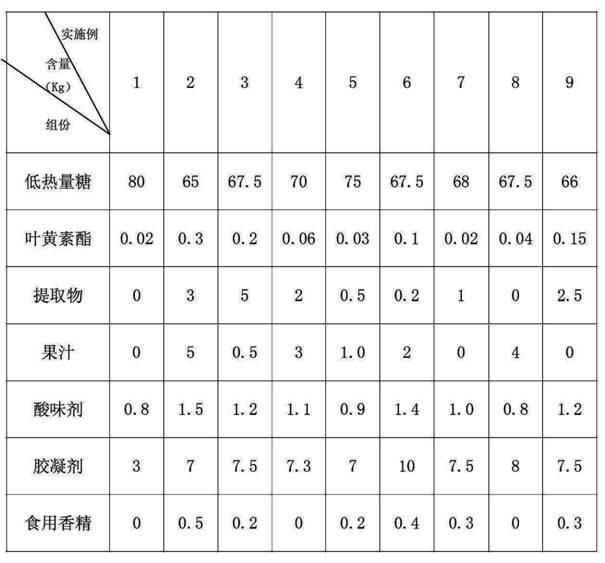

Examples

Embodiment 1

[0057] Preparation:

[0058] (1) Boil sugar: Take 100 Kg of maltitol syrup (80wt%) and add 10 kg of water, put it in a sugar pot with a stirrer, and cook at a controlled temperature of 105°C to 120°C under stirring until the sugar liquid is clear and transparent , continue to boil to contain solids 86Brix, to the end of boiling sugar.

[0059] (2) Chemical glue: Take 3Kg of pectin into the chemical glue tank, add purified water 25 times the mass of pectin, and slowly heat up to 70-100°C while stirring, and continue stirring until the pectin swells completely to obtain a transparent homogeneous Colloidal sol. (3) Add 0.5Kg of water-soluble lutein ester powder (4wt%) to 3 times of water at 70-80°C to dissolve for later use.

[0060] (4) Preparation of sour agent solution: Take 0.3Kg of malic acid and 0.5Kg of citric acid and add appropriate amount of purified water to prepare a 50wt% solution for later use.

[0061] (5) Material-liquid mixing: Add the swollen pectin solution ...

Embodiment 2

[0064] Preparation:

[0065] (1) Boil sugar: Take 65 Kg of maltitol and add 7KG of water, put it in a sugar pot with a stirrer, and cook at a controlled temperature of 105°C to 120°C under stirring until the sugar solution is clear and transparent, and continue to boil until it contains Solids 88Brix, until the end of boiling sugar.

[0066] (2) Chemical glue: Take 6Kg of gelatin into the chemical glue tank, add 1.5 times of purified water, slowly heat up to 60°C-70°C, swell while stirring, until the swelling is complete, and it becomes a transparent homogeneous sol; take another 0.5Kg of agar , to another gel tank, add purified water 22 times the weight of the agar, slowly raise the temperature to 100°C, cook while stirring, until the agar swells and completely gels.

[0067] (3) Add 2.0Kg of lutein ester microcapsules (15wt%) into 5Kg of concentrated orange juice (100wt%), dissolve evenly, and set aside.

[0068] (4) Add 0.5Kg of bilberry extract and 2.5Kg of water-soluble...

Embodiment 3

[0073] Preparation:

[0074] (1) Boil sugar: Take 15Kg of isogalacto-oligosaccharide, 15Kg of fructo-oligosaccharide, 50 Kg of isomalto-oligosaccharide syrup (75wt%), add 8KG, put it in a sugar pot with a stirrer, and stir it. Control the temperature at 105°C to 120°C and boil until the sugar liquid is clear and transparent, continue to boil until the solid content is 85 Brix, and reach the end of the sugar boil.

[0075] (2) gelatinization: get 7 Kg of gelatin and put it into the tank, and melt the gelatin liquid in the same step as in Example 2; get 0.5 Kg of agar in addition and melt in the same step in Example 2 to obtain the agar liquid.

[0076] (3) Take 2.0Kg of water-soluble lutein ester powder (10wt%), add 3 times of it to 70-80°C water and dissolve it for later use.

[0077] (4) Add 5 Kg of collagen to 0.625Kg of concentrated apple juice (80wt%), stir until uniform, and set aside.

[0078] (5) Preparation of sour agent solution: Take 0.6Kg of malic acid and 0.6Kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com