Method for preparing cefixime dispersible tablets

A technology of cefixime and dispersible tablets, which is applied in the field of preparation of anti-infective cefixime dispersible tablets and cefixime dispersible tablets, can solve the problem of slow dissolution rate, insufficient bioavailability and failure to achieve complete Dissolution and other problems, to achieve the effect of complete dissolution and fast dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

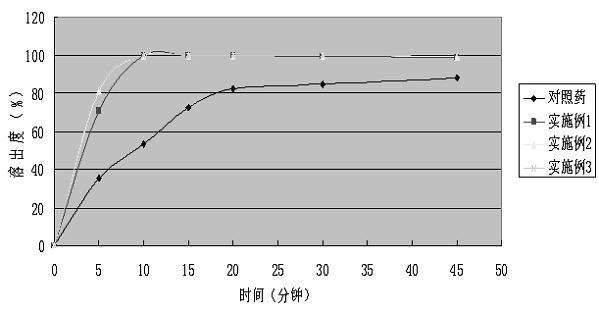

Image

Examples

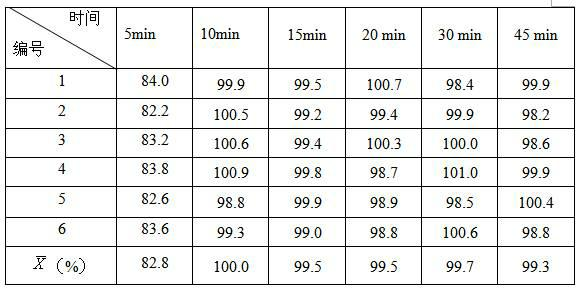

Embodiment 1

[0040] Example 1 Cefixime Dispersible Tablet Prescription Ⅰ:

[0041] Cefixime 500g (18.7%)

[0042] Microcrystalline Cellulose 850g (31.8%)

[0043] Pregelatinized starch 190g (7.1%)

[0044] Sodium starch glycolate 300g (11.2%)

[0045] 2% hypromellose aqueous solution 800g (29.9%)

[0046] Magnesium Stearate 15g (0.56%)

[0047] Sodium Lauryl Sulfate 20g (0.75%)

[0048] Made into 10000 pieces

[0049] The preparation process is as follows:

[0050]500g of cefixime bulk drug was micronized into a powder with a particle size between 20 μm and 120 μm, mixed evenly with 200 g of microcrystalline cellulose, and dried into dry granules by a dry granulator to obtain material 1. 16 g of hydroxypropyl methylcellulose (another name called hypromellose) and 20 g of sodium lauryl sulfate were dissolved in 764 g of water to obtain a binder solution. The...

Embodiment 2

[0051] Example 2 Cefixime Dispersible Tablets Prescription Ⅱ:

[0052] Cefixime 500g (17.6%)

[0053] Microcrystalline Cellulose 200g (7.1%)

[0054] Lactose 1000g (35.3%)

[0055] Crospovidone 300g (10.6%)

[0056] 2% hypromellose aqueous solution 800g (28.2%)

[0057] Magnesium Stearate 15g (0.5%)

[0058] Tween 80 20g (0.7%)

[0059] Made into 10000 pieces

[0060] The preparation process is as follows:

[0061] 500g of cefixime bulk drug was micronized into a powder with a particle size between 20 μm and 120 μm, mixed evenly with 200 g of lactose, and dried into dry granules by a dry granulator to obtain material 1. 16 g of hypromellose and 20 g of Tween 80 were dissolved in 764 g of water to obtain a binder solution. Mix the remaining 1000g of lactose with 200g of microcrystalline cellulose and 200g of crospovidone evenly, use t...

Embodiment 3

[0062] Example 3 Cefixime Dispersible Tablets Prescription Ⅲ:

[0063] Cefixime 500g

[0064] Starch 800g

[0065] Lactose 500g

[0066] Croscarmellose Sodium 200g

[0067] 5% povidone K30 aqueous solution 800g

[0069] Tween 80 20g

[0070] Made into 10000 pieces

[0071] The preparation process is as follows:

[0072] 500g of cefixime bulk drug was micronized into a powder with a particle size between 20 μm and 120 μm, mixed evenly with 300 g of starch, and dried into dry granules by a dry granulator to obtain material 1. 40 g of povidone K30 and 20 g of Tween 80 were dissolved in 740 g of water to obtain a binder solution. Mix the remaining 500g of lactose with 500g of starch and 100g of croscarmellose sodium evenly, use the above-mentioned adhesive to make wet granules, dry and granulate the wet granules to obtain ...

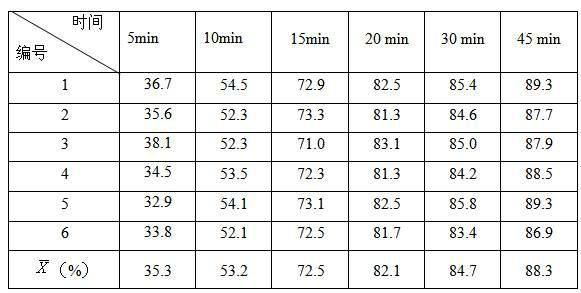

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com