Magnetically supported silver bromide photochemical catalysis material and preparation method thereof

A photocatalytic material, silver bromide technology, applied in the field of photocatalysis, can solve problems such as difficult to recycle and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

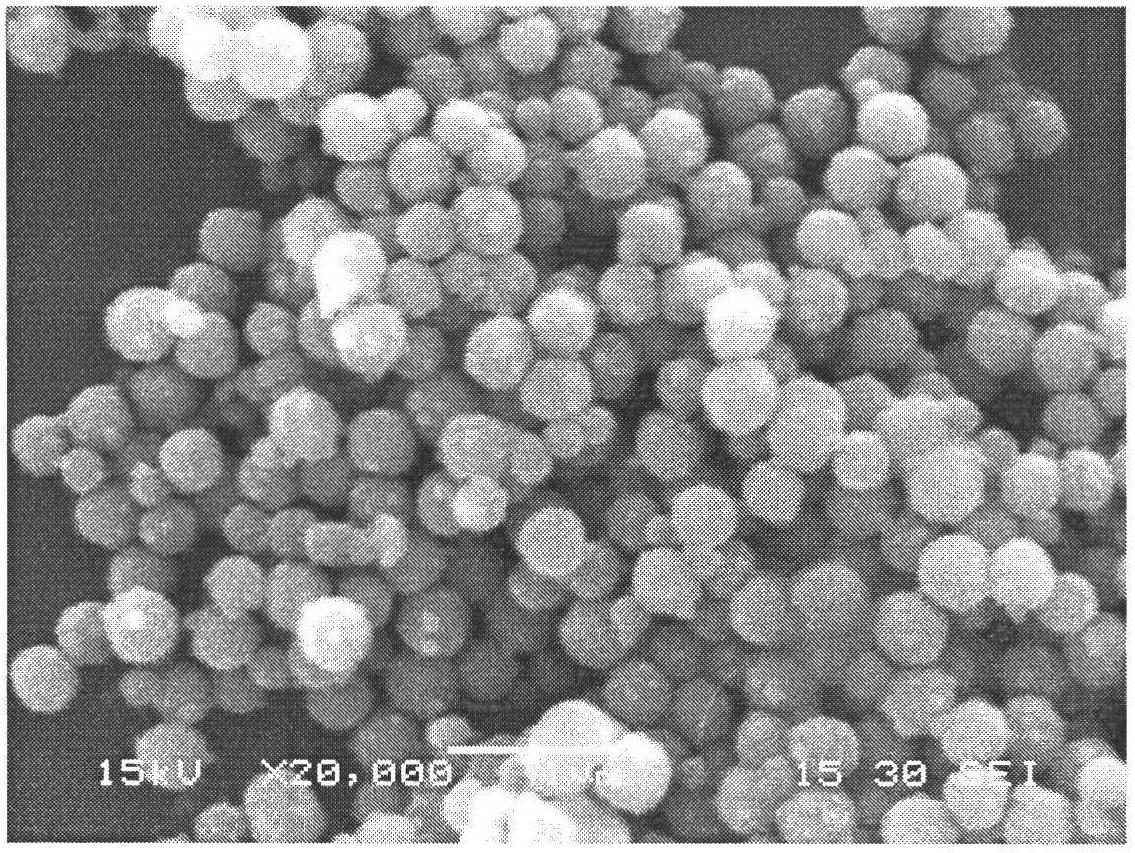

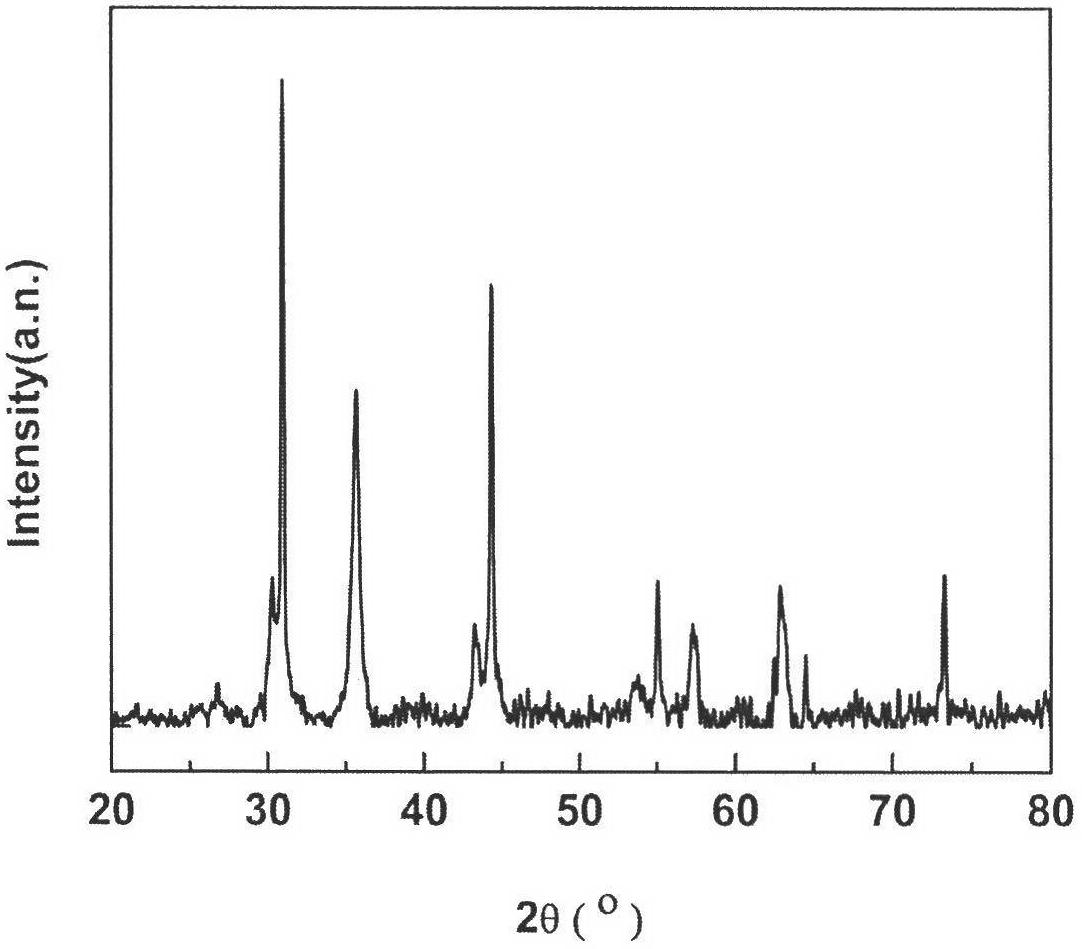

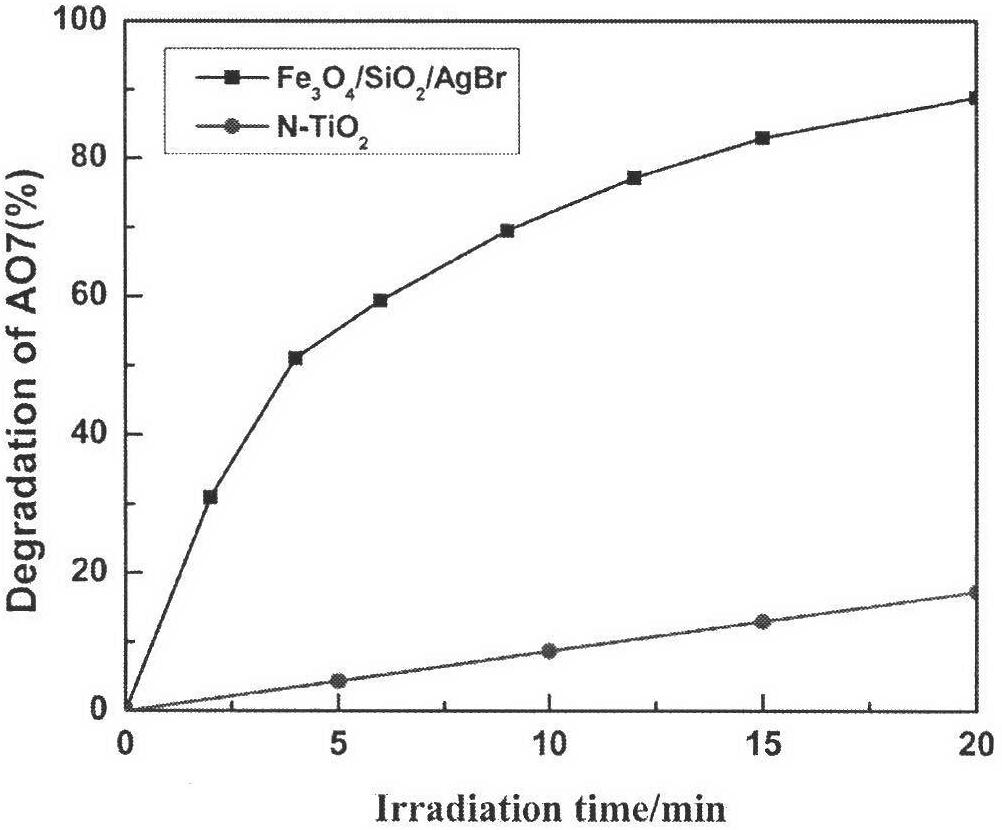

Embodiment 1

[0022] Dissolve ferric chloride in ethylene glycol, add anhydrous sodium acetate and 24g / L polyethylene glycol, stir the mixture vigorously for 30 minutes, and then carry out hydrothermal reaction. After the reaction, wash three times with absolute ethanol and secondary water respectively, and disperse in absolute ethanol; take the above-mentioned ethanol solution, add absolute ethanol, secondary water, ultrasonically disperse, and slowly add dropwise ethyl orthosilicate ( The molar ratio of ethyl orthosilicate to ferric oxide is 1:1), quickly add ammonia water dropwise, and keep ultrasonic reaction at room temperature. After the end, wash with absolute ethanol and secondary water several times, magnetically separate, and disperse in water; under ultrasonic and mechanical stirring conditions, take the above-mentioned product, add silver nitrate and ammonia water quickly, and slowly add potassium bromide (bromide) The molar ratio of potassium to ferric oxide is 1:1) aqueous sol...

Embodiment 2

[0025] Dissolve ferric chloride in ethylene glycol, add anhydrous sodium acetate and 12g / L polyethylene glycol, stir the mixture vigorously for 30 minutes, and then carry out hydrothermal reaction. After the reaction, wash three times with absolute ethanol and secondary water respectively, and disperse in absolute ethanol; take the above-mentioned ethanol solution, add absolute ethanol, secondary water, ultrasonically disperse, and slowly add dropwise ethyl orthosilicate ( The molar ratio of ethyl orthosilicate to ferric oxide is 1:1), quickly add ammonia water dropwise, and keep ultrasonic reaction at room temperature. After the end, wash with absolute ethanol and secondary water several times, magnetically separate, and disperse in water; under ultrasonic and mechanical stirring conditions, take the above-mentioned product, add silver nitrate and ammonia water quickly, and slowly add potassium bromide (bromide) The molar ratio of potassium to ferric oxide is 1:1) aqueous sol...

Embodiment 3

[0027] Dissolve ferric chloride in ethylene glycol, add anhydrous sodium acetate and 24g / L polyethylene glycol, stir the mixture vigorously for 30 minutes, and then carry out hydrothermal reaction. After the reaction, wash three times with absolute ethanol and secondary water respectively, and disperse in absolute ethanol; take the above-mentioned ethanol solution, add absolute ethanol, secondary water, ultrasonically disperse, and slowly add dropwise ethyl orthosilicate ( The molar ratio of ethyl orthosilicate to ferroferric oxide is 1.2:1), quickly add ammonia water dropwise, and keep ultrasonic reaction at room temperature. After the end, wash with absolute ethanol and secondary water several times, magnetically separate, and disperse in water; under ultrasonic and mechanical stirring conditions, take the above-mentioned product, add silver nitrate and ammonia water quickly, and slowly add potassium bromide (bromide) The molar ratio of potassium to ferric oxide is 1:1) aque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com