Waste liquid crystal display panel treatment and resource recycling method

A technology of liquid crystal display panels and recycling methods, applied in the direction of solid waste removal, etc., can solve the problems of long processing time, secondary pollution, and low efficiency, and achieve the effects of clean processing, high resource utilization rate, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

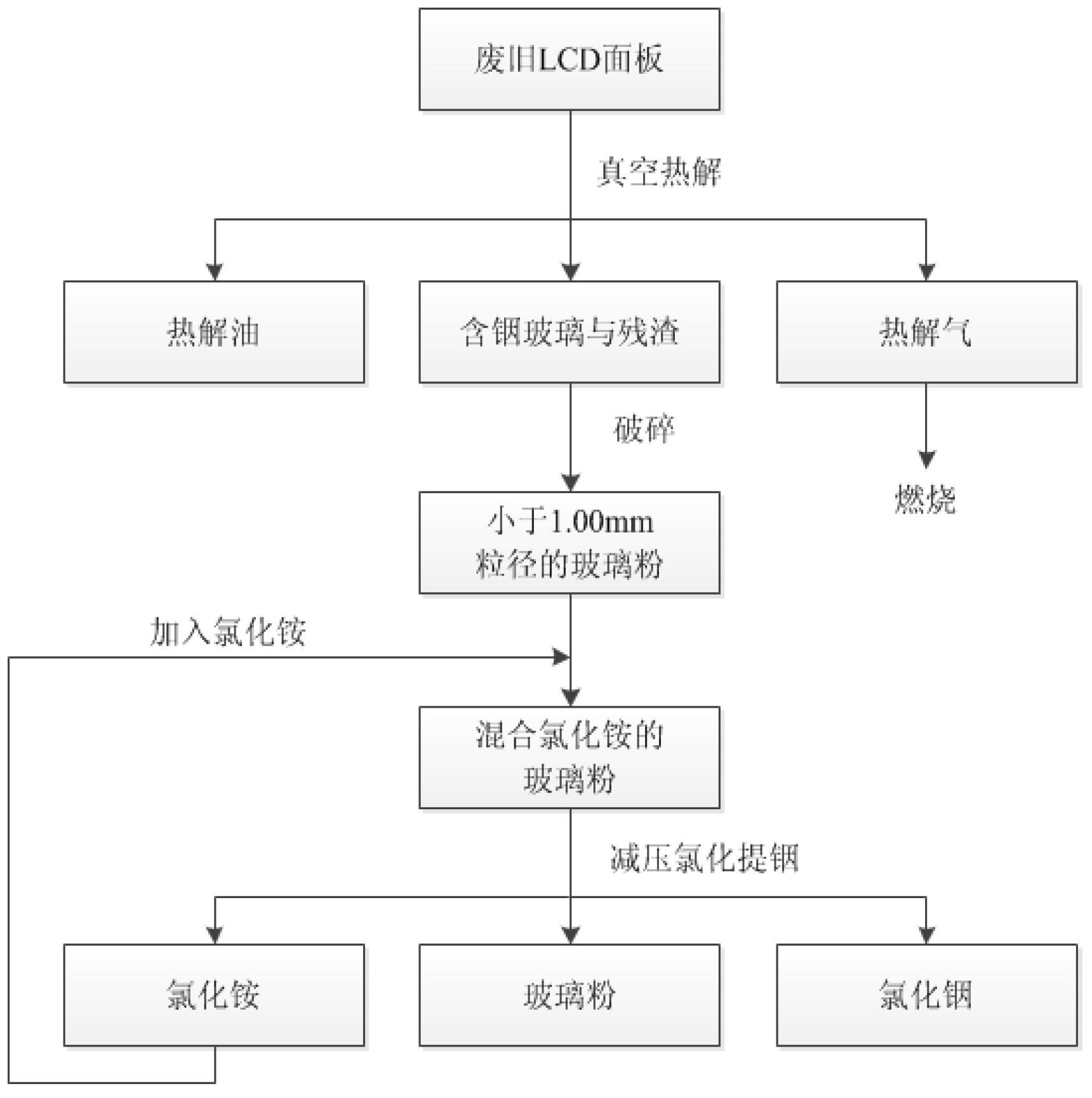

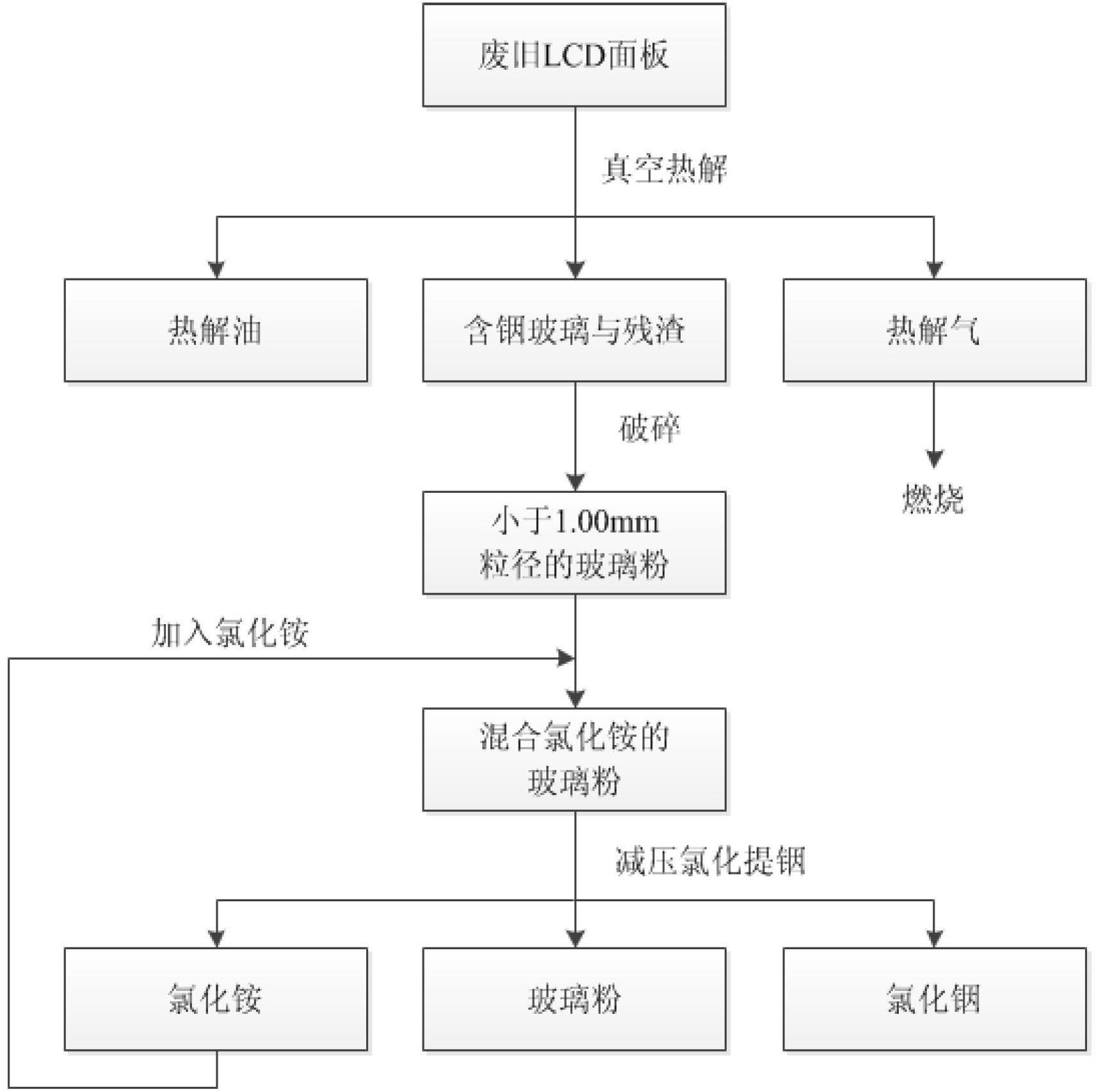

Method used

Image

Examples

Embodiment 1

[0045] First, send the disassembled waste liquid crystal display panel into the vacuum pyrolysis furnace. After the vacuum furnace is sealed, start the vacuum pump to pump air, so that the vacuum degree of the vacuum pyrolysis furnace reaches 1Pa, and the temperature of the condensation part of the vacuum pyrolysis furnace is controlled at 0-50 °C, start the vacuum pyrolysis furnace heater, make the temperature of the heating part reach 550 °C, and carry out pyrolysis for 60 minutes, so that the organic components on the waste liquid crystal display surface are rapidly pyrolyzed and gasified, extracted and condensed and collected. 75.2% pyrolysis oil, 10.7% pyrolysis gas and 14.1% pyrolysis residue were obtained. Afterwards, the remaining indium-containing glass was taken out and crushed to less than 1.00mm, and after the crushing, 50wt% ammonium chloride was added and mixed thoroughly. Heating the raw material reactor of the decompression chlorination and extracting indium eq...

Embodiment 2

[0047] First, send the disassembled waste liquid crystal display panel into the vacuum pyrolysis furnace. After the vacuum furnace is sealed, start the vacuum pump to pump air, so that the vacuum degree of the vacuum pyrolysis furnace reaches 50Pa, and the temperature of the condensation part of the vacuum pyrolysis furnace is controlled at 0-50 °C, start the vacuum pyrolysis furnace heater, make the temperature of the heating part reach 600 °C, and carry out pyrolysis for 100 minutes, so that the organic components on the waste liquid crystal display surface are quickly pyrolyzed and gasified, extracted and condensed and collected. 71.9% of pyrolysis oil, 13.2% of pyrolysis gas and 14.9% of pyrolysis residue were obtained. Afterwards, the remaining indium-containing glass was taken out and crushed to less than 1.00mm, and after the crushing, 60wt% ammonium chloride was added and mixed thoroughly. Heating the raw material reactor of the decompression chlorination and extractin...

Embodiment 3

[0049] First, send the disassembled waste liquid crystal display panel into the vacuum pyrolysis furnace. After the vacuum furnace is sealed, start the vacuum pump to pump air, so that the vacuum degree of the vacuum pyrolysis furnace reaches 100Pa, and the temperature of the condensation part of the vacuum pyrolysis furnace is controlled at 0-50 °C, start the vacuum pyrolysis furnace heater, make the temperature of the heating part reach 700 °C, and carry out pyrolysis for 120 minutes, so that the organic components on the waste liquid crystal display surface are quickly pyrolyzed and gasified, extracted and collected by condensation. 70.1% of pyrolysis oil, 13.26% of pyrolysis gas and 16.64% of pyrolysis residue were obtained. Afterwards, the remaining indium-containing glass was taken out and crushed to less than 1.00mm, and after crushing, 70wt% ammonium chloride was added and mixed thoroughly. Heating the raw material reactor of the decompression chlorination and extracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com