Ultrasonic microwave hydrothermal synergistic strengthening method and equipment for preparing high-purity ammonium paratungstate

A pure ammonium paratungstate, microwave hydrothermal technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of inability to carry out production, rising production costs, increasing difficulty in operation, etc., and achieve accurate maintenance of constant temperature and heating rate. Fast and efficient heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

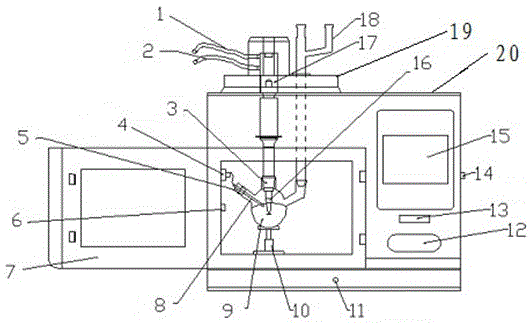

[0042] In order to make the technical means, creative features, work flow, and use methods of the present invention achieve the purpose and effect easily understood, the present invention will be further described below in conjunction with specific illustrations.

[0043] like image 3As shown, the equipment for the preparation of high-purity ammonium paratungstate by ultrasonic microwave hydrothermal synergistic strengthening, that is, the crystallizer, includes a microwave oven, and the microwave oven includes a furnace door 7 and a furnace body 20, and the furnace body 20 is provided with a magnetic stirrer, a microwave generator device 25 and fault detection module 24, a tray 10 is provided in the inner cavity of the furnace body 20, a three-necked flask 8 is placed on the pressure sensor 21 provided on the tray 10, and a sensor socket 4 and a camera 6 are arranged on the side wall of the inner cavity. Sensor socket 4 connects temperature sensor 8, and temperature sensor 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com