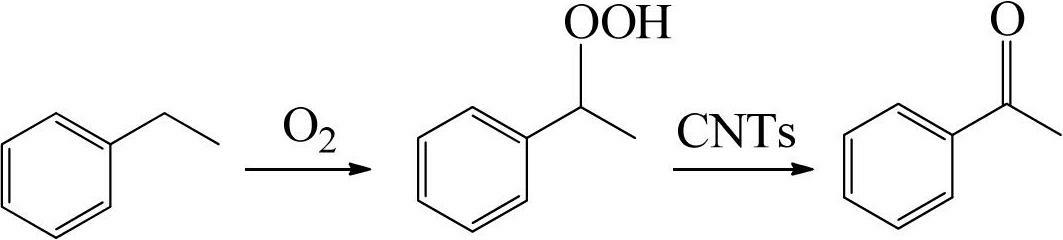

Method for producing acetophenone through catalytic oxidation of ethylbenzene

A technology for catalytic oxidation and acetophenone, which is applied in the preparation of carbonyl compounds by oxidation, organic chemistry, etc., can solve the problems of difficult separation and recovery of catalysts, inability to recycle and reuse, loss of active components, etc., and achieve easy separation and recycling , Avoid equipment corrosion, strong corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 8.7 g of ethylbenzene and acetonitrile, tert-butyl hydroperoxide and multi-walled carbon nanotubes were added into a closed reaction kettle and mixed to form a mixed suspension. Wherein, the weight ratio of acetonitrile to ethylbenzene is 5.5:1, the weight ratio of multi-walled carbon nanotubes to ethylbenzene is 0.0229:1, and the weight ratio of tert-butyl hydroperoxide to ethylbenzene is 0.03:1. The mixed suspension is heated to 155°C under stirring, and oxygen is introduced to 1.5MPa. Since the reaction process continuously consumes oxygen in a stoichiometric ratio, it is continuously replenished through a pressure stabilizing device and a flow meter connected to an oxygen source during the reaction. Oxygen and keep the pressure constant at 1.5MPa. After reacting for 4 hours, the liquid-solid phase mixture was discharged from the bottom of the reaction kettle, and it was filtered to obtain a solid catalyst and a liquid phase mixture. The liquid phase mixture was anal...

Embodiment 2

[0036] Add 8.7g of ethylbenzene, acetonitrile, and multi-walled carbon nanotubes into a closed reaction kettle and mix to form a mixed suspension. Wherein, the weight ratio of acetonitrile to ethylbenzene is 5.5:1, and the weight ratio of multi-walled carbon nanotubes to ethylbenzene is 0.0229:1. The mixed suspension was heated to 155° C. with stirring, and oxygen was introduced to 1.0 MPa. Oxygen is continuously replenished and kept at a constant pressure of 1.0 MPa through a pressure stabilizing device and a flow meter connected to an oxygen source during the reaction process because oxygen is continuously consumed in a stoichiometric ratio. After reacting for 4 hours, the liquid-solid phase mixture was discharged from the bottom of the reaction kettle, and it was filtered to obtain a solid catalyst and a liquid phase mixture. The liquid phase mixture was analyzed to determine the conversion rate and selectivity of the reaction. The separation and analysis methods of the pr...

Embodiment 3

[0038]8.7 g of ethylbenzene and acetonitrile, phenylethyl hydroperoxide and multi-walled carbon nanotubes were added into a closed reaction kettle and mixed to form a mixed suspension. Among them, the weight ratio of acetonitrile to ethylbenzene is 5.5:1, the weight ratio of multi-walled carbon nanotubes to ethylbenzene is 0.0229:1, and the weight ratio of phenylethyl hydroperoxide to ethylbenzene is 0.03:1. The mixed suspension was heated to 155° C. with stirring, and oxygen was introduced to 2.5 MPa. Oxygen is constantly replenished and kept at a constant pressure of 2.5 MPa through a pressure stabilizing device and a flow meter connected to an oxygen source during the reaction process because oxygen is continuously consumed in a stoichiometric ratio. After reacting for 4 hours, the liquid-solid phase mixture was discharged from the bottom of the reaction kettle, and it was filtered to obtain a solid catalyst and a liquid phase mixture. The liquid phase mixture was analyzed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com