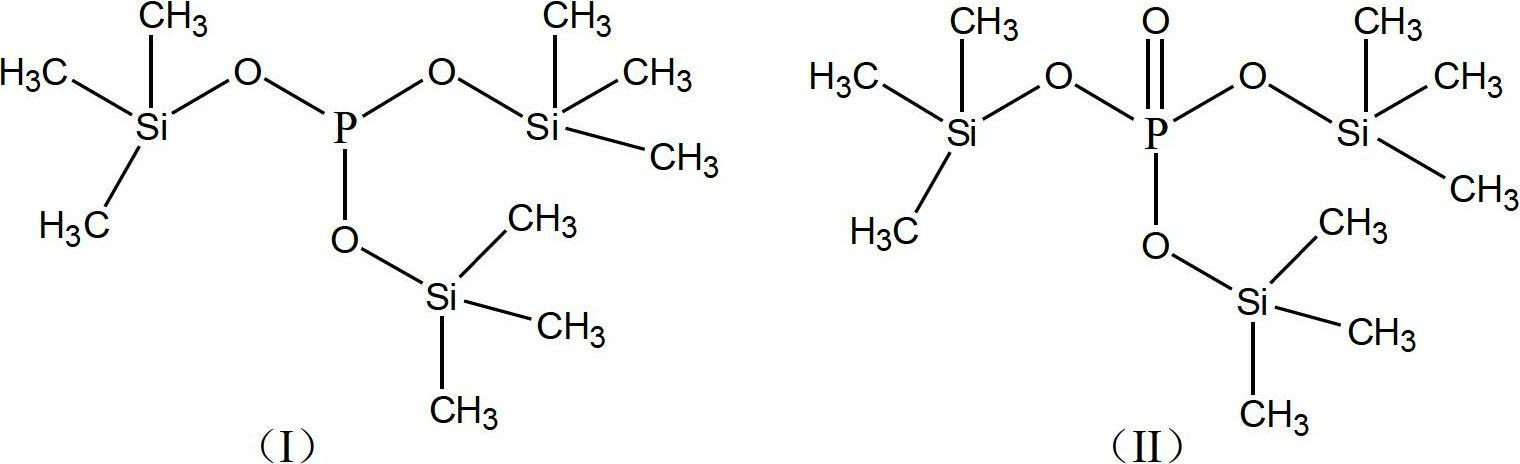

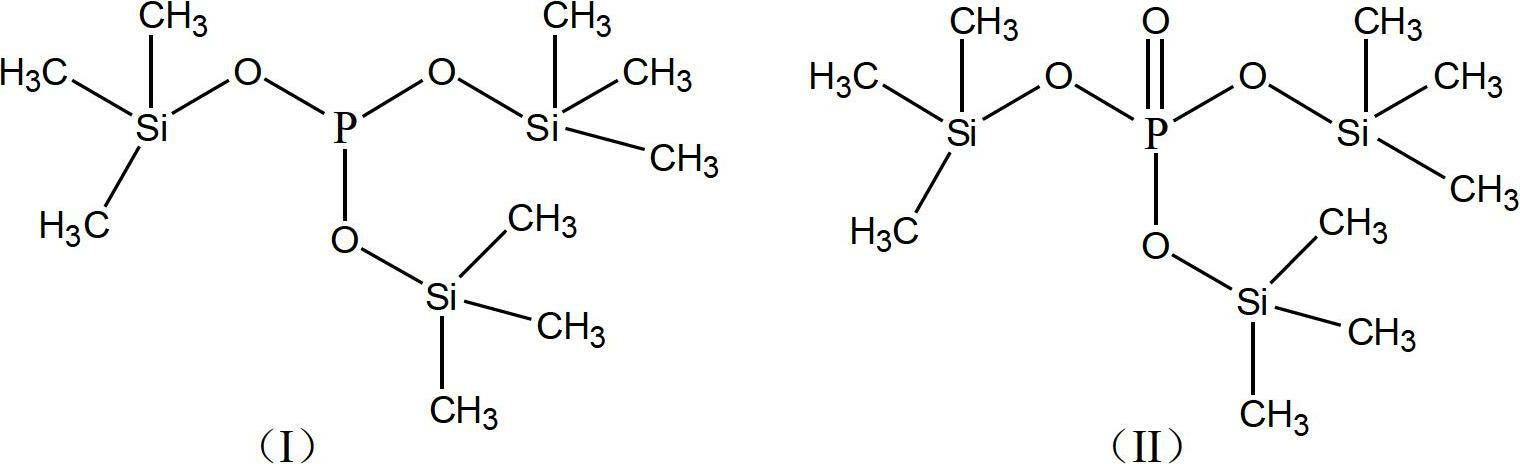

Purification method of tri (trimethylsililyl) phosphite ester and tri (trimethylsililyl) phosphate ester

A technology of trimethylsilyl and phosphite, which is applied in chemical instruments and methods, phosphorus organic compounds, compounds of Group 5/15 elements of the periodic table, etc. High-purity products, unstable product quality, etc., to achieve the effect of being conducive to stable storage or long-distance transportation, environment-friendly, and not easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Under the protection of nitrogen, add 1680g of tris(trimethylsilyl)phosphate with a content of 60% to a 2000mL three-necked flask, the water content is 2600ppm, add 168g of phenothiazine, and pass through a rectification device with an adjustable reflux ratio under normal pressure. Carry out fractional distillation and purification, collect fractions at 115~120°C / 0.2~5KPa to obtain 825g of tris(trimethylsilyl)phosphate, and the content of the product measured by gas chromatography (GC-2014, purchased from Shimadzu company) is 99.9035% , The content of phenothiazine is 112ppm.

Embodiment 2

[0024] Under nitrogen protection, add 1550g of tris(trimethylsilyl)phosphate with a content of 90% to a 2000mL three-necked flask with a water content of 800ppm, add 1.6g of 2,6-di-tert-butyl p-cresol, and adjust the The rectification device with the reflux ratio conducts fractional distillation and purification under reduced pressure, collects the fraction at 125~128°C / 5~10KPa, and obtains 1182g of tris(trimethylsilyl)phosphate, which is passed through a gas chromatograph (GC-2014, purchased from Shimadzu Company) measured that the content of the product was 99.9216%, and the content of 2,6-di-tert-butyl-p-cresol was 18ppm.

Embodiment 3

[0026] Under nitrogen protection, 758g of tris(trimethylsilyl)phosphite with a content of 96% was added to a 1000mL three-necked flask, and the water content was 128ppm. 7g of butylhydroxyanisole and 5g of tert-butylhydroquinone were added, Fractional distillation and purification were carried out under reduced pressure through a rectification device with an adjustable reflux ratio, and the fraction at 80~86°C / 2~5KPa was collected to obtain 662g of tris(trimethylsilyl)subite, which was passed through a gas chromatograph (GC-2014 , purchased from Shimadzu company) measured product content is 99.9525%, butylated hydroxyanisole content is 21ppm, tertiary butyl hydroquinone content is 45ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com